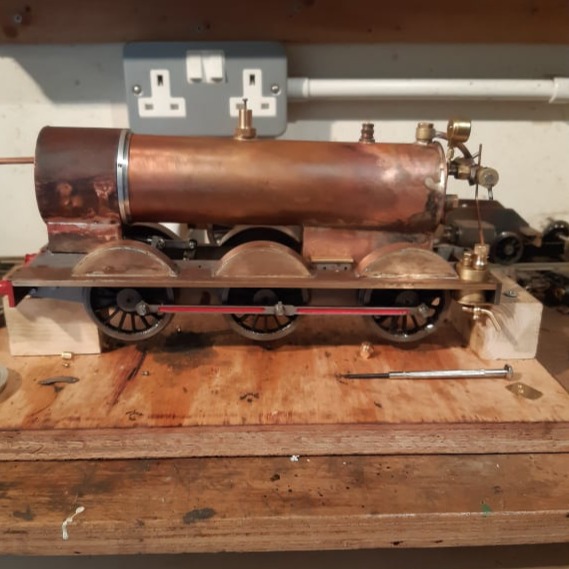

The Project Gauge 1 Locomotive

Following the issue found on Girton chassis. It was decided to follow the Gauge 1 Model Railway Association "Project" book, which was a fully described design for a single cylinder, high pressure locomotive, designed with a beginner in mind.

This page doesn't detail all the building steps for the locomotive, these are best taken from the book, rather, this page just details deviations from the plans or adds comments to the design which might be helpful to other builders.

To get started, the frames and connecting rods were purchased already laser cut. This time from Walsall Model Industries, who also supplied the wheel castings, buffers and a steam dome for the build.