Gauge 1. Girton - Locomotive

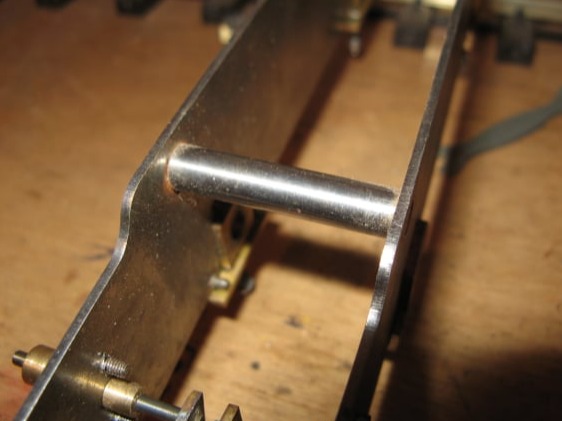

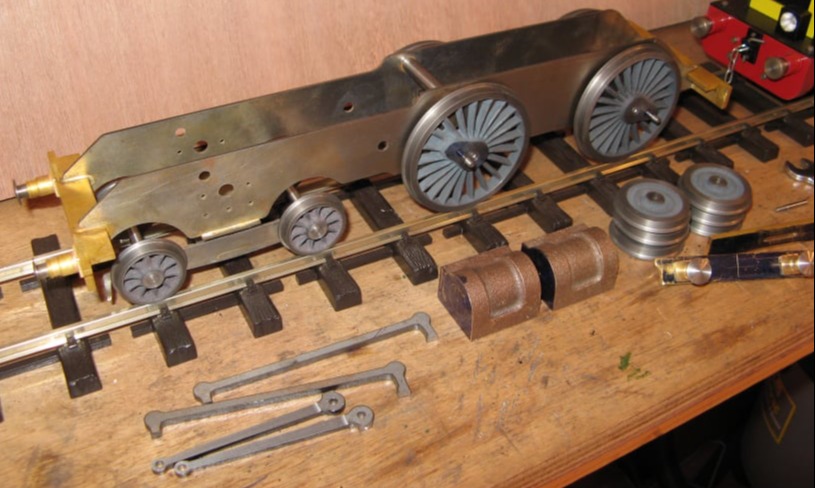

The main locomotive frames and the front bogie frames were all parts supplied in the kit of laser cut parts from Model engineer's Laser.

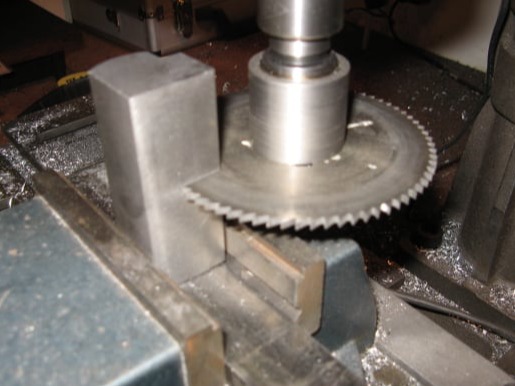

The kit also included some of the motion gear, and the tender frames.

The wheel castings were supplied by Walsall Model Industries.