The MK1 Steam Engine

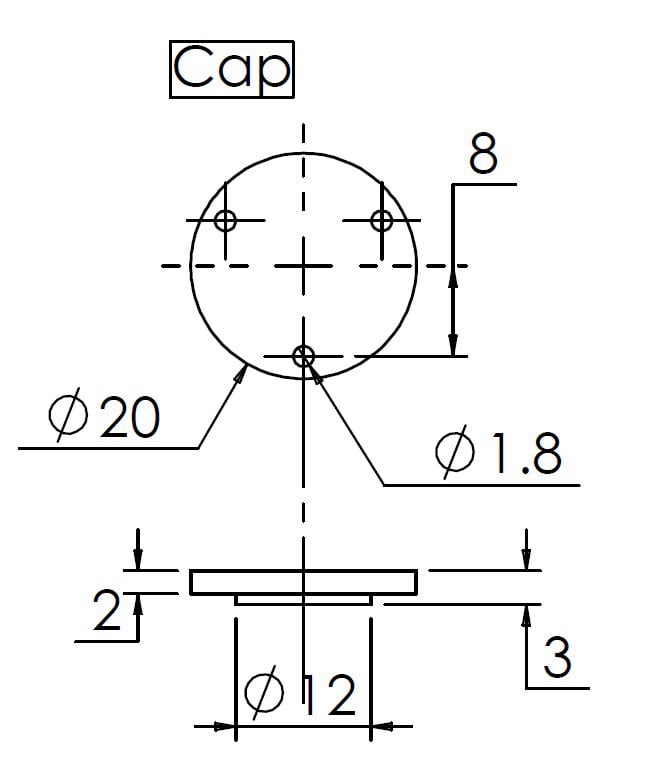

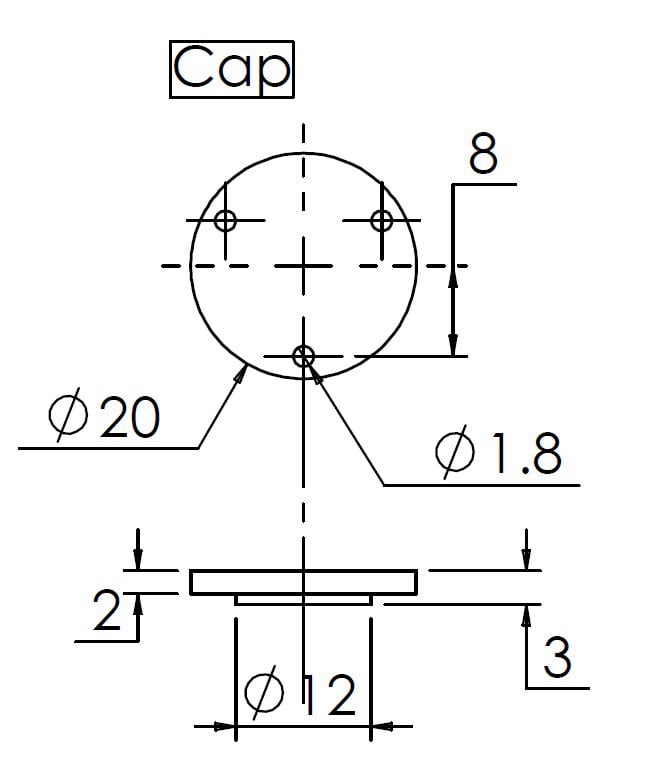

Cylinder Cap

The end cap is simple turning job from a short piece of bar.

It has no critical dimensions, but it helps for the shoulder to sit snug inside the cylinder bore to aid location and sealing.

The end cap is simple turning job from a short piece of bar.

It has no critical dimensions, but it helps for the shoulder to sit snug inside the cylinder bore to aid location and sealing.

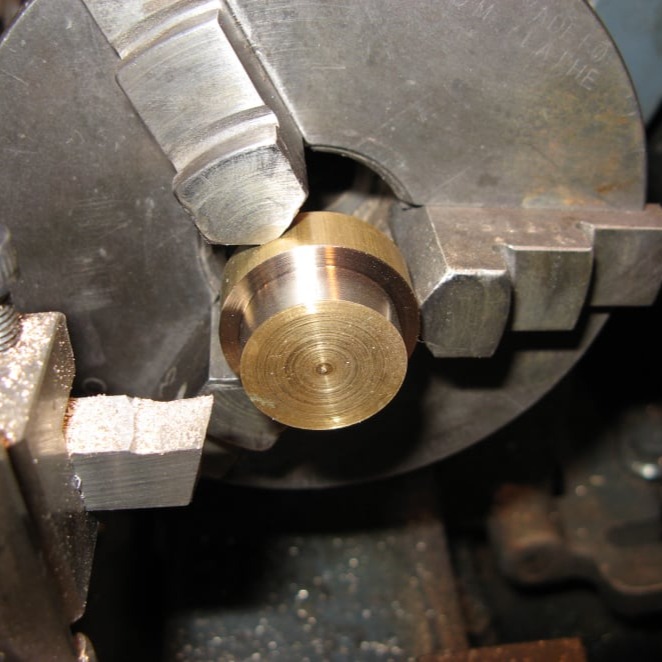

First the outer diameter of the cap should be turned.

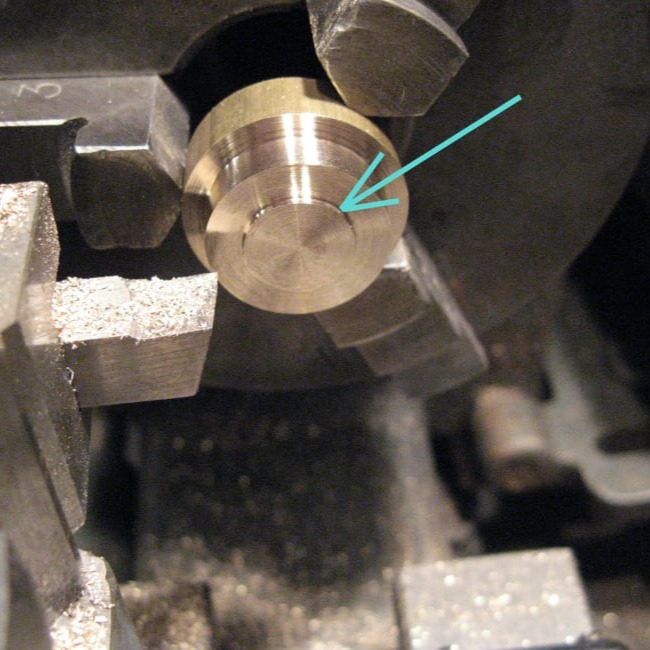

Then the shoulder added, using the cylinder bore as a gauge to get the correct diameter. A sharp tool is needed here, to eliminate any radius between the shoulder and the cap (arrowed).

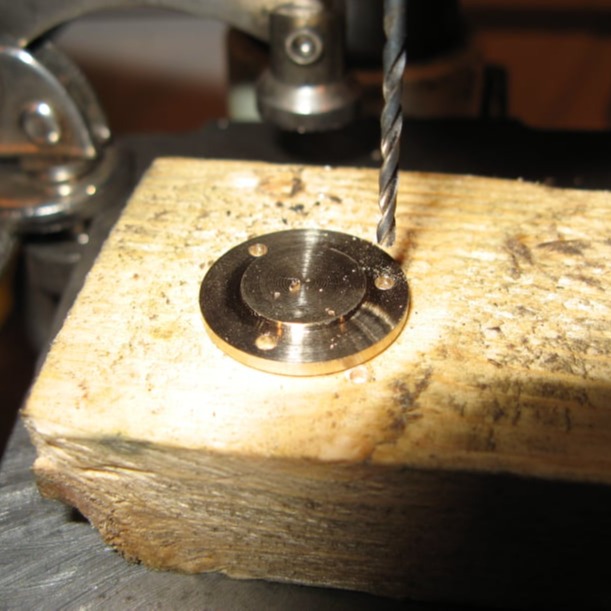

As with the bearing, 3 evenly space holes can be marked around the cap using a spirit level and a punch mounted in the tool post.

The cap should be parted from the bar using a slow speed and feed on the lathe. Part way through the tool can be retracted and a file touched against the work to remove any burrs. Then the part can be parted-off completely.

Finally the cap mounting holes can be drilled on the pillar drill using a 1.8mm drill to take the 10BA mounting bolts.

Mobirise