Checking the Honda S90 Gearbox

Following a couple of test drives, the gearbox was found to be jumping out of second gear.

This page details the investigation and rework that was done to correct the problem.

Following a couple of test drives, the gearbox was found to be jumping out of second gear.

This page details the investigation and rework that was done to correct the problem.

Parts removed to access gearbox.

Inside the gearbox.

The selector forks were worn.

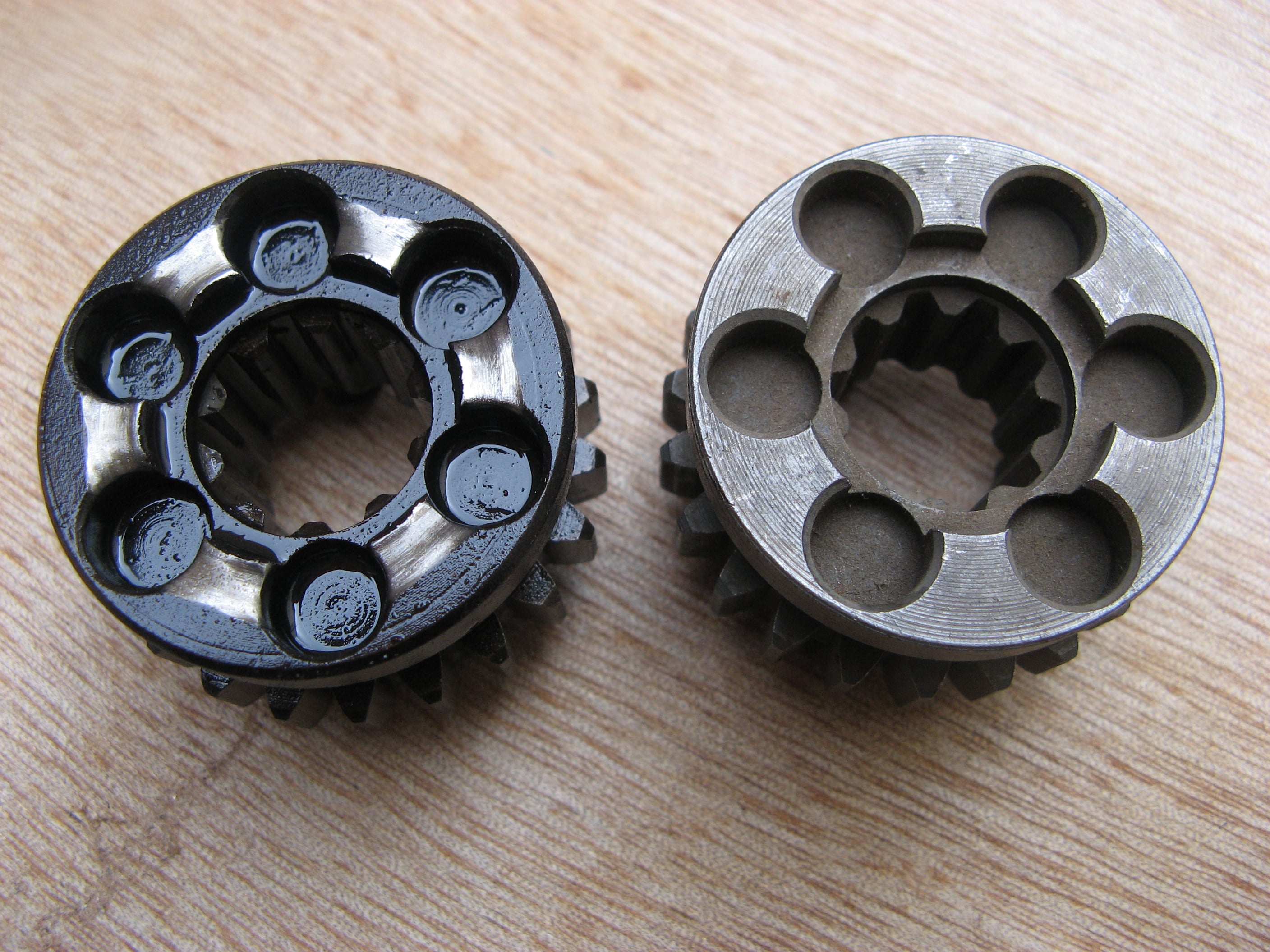

The dog teeth were worn on 2nd gear.

The dog teeth holes in the second gear were worn at the edge.

The replacement parts showed just how worn the old parts were and explained the jumping gear.

The selector drum was inspected for wear. The grooves were supposed to be a maximum width of 6.4mm. They were approximately 6.1mm throughout.

The clearance between the drum and the fork sleeves was acceptable ie: less than 0.025mm.

However, the bolts that rode in the selector barrel were worn, but by good fortune, by swapping them between the selector forks, new faces were exposed to the slot sides to giving a tighter fit in the grooves. This was possible because the start position of the thread was different in each of the forks.

The worn selector fork had brass tips brazed on to build them up.

Now the bike was usable and provided many miles of smiles with some commutes and day trips on quieter roads.

AI Website Builder