Stuart 10H Steam Plant

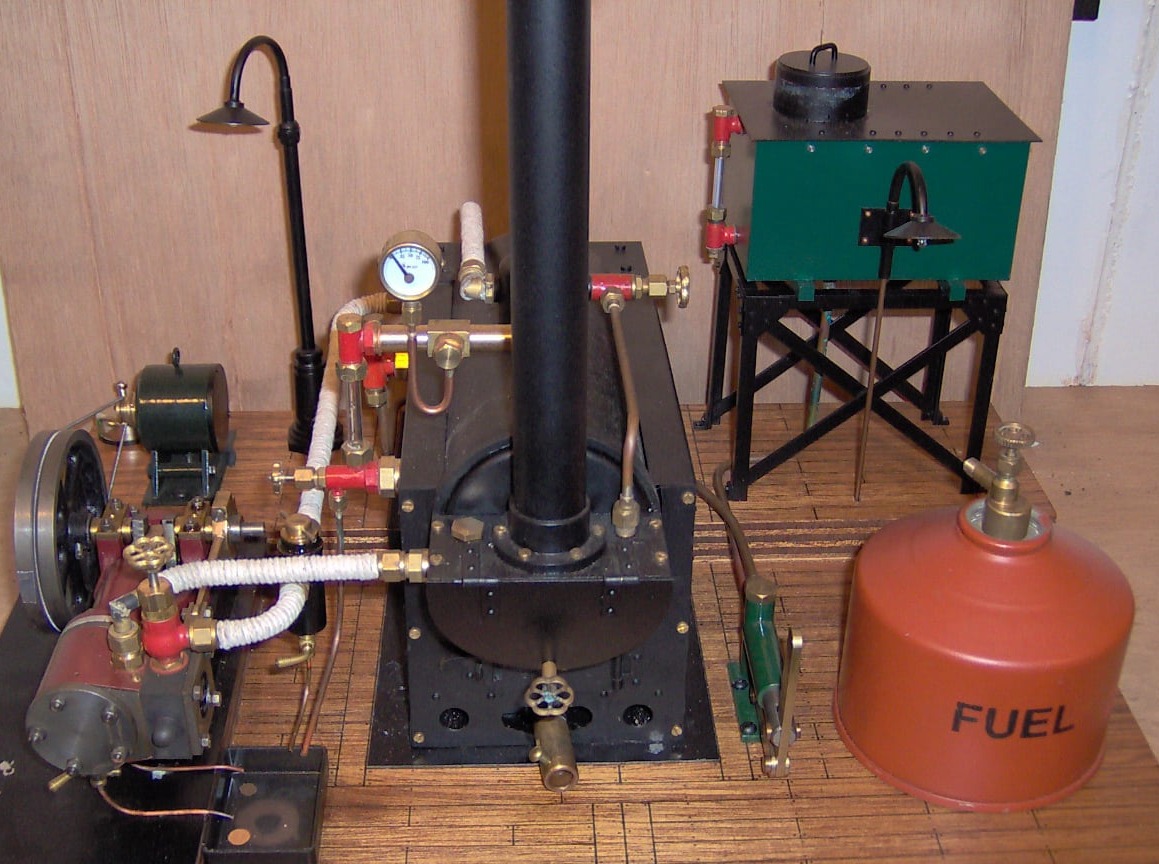

This early model was designed to put the Stuart 10H steam engine to work and included a gas fired boiler, generator, two lamps and a water tower.

This early model was designed to put the Stuart 10H steam engine to work and included a gas fired boiler, generator, two lamps and a water tower.

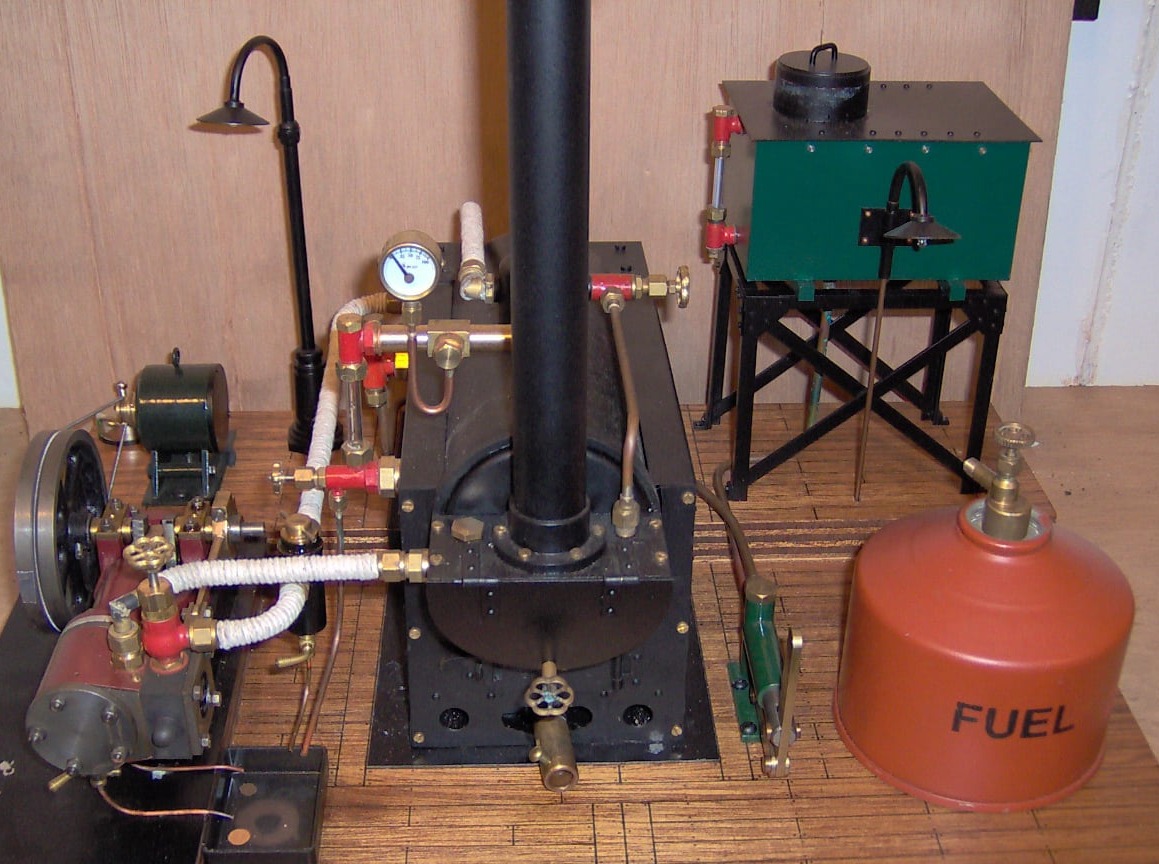

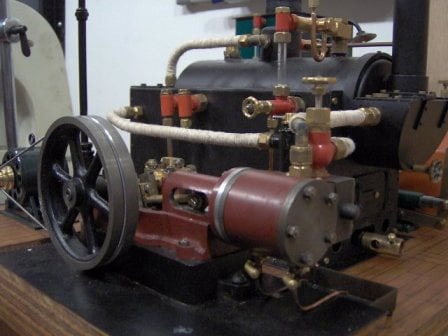

The boiler was a horizontal return tube boiler. This design had both the fire box and smoke box located at the front of the boiler drum. The fire would be placed under the front half of the pressure vessel and the hot gasses would pass to the back of the firebox and return to the front via the fire tubes.

The boiler had a total of 12 fire tubes and design pressure of 60psi.

Other fittings for the boiler included a pressure gauge, water gauge, blower valve, safety valve, super heater and water feed heater.

The boiler design is shown here.

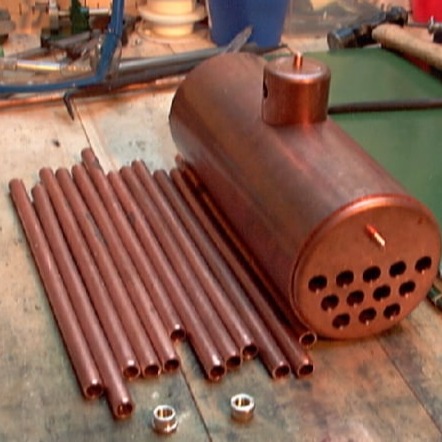

The engine was made from a Stuart 10H Casting kit.

This was the horizontal version of the Stuart 10. The engine had a bore and stroke of 3/4" (19mm) and a flywheel diameter of 3" (75mm). It would run up to 3000rpm, but was most happy at about 800rpm.

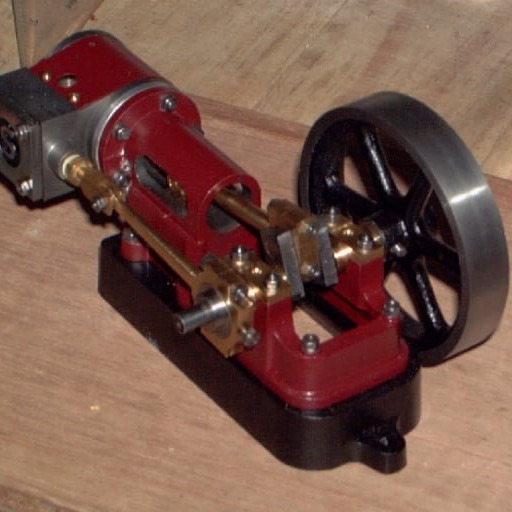

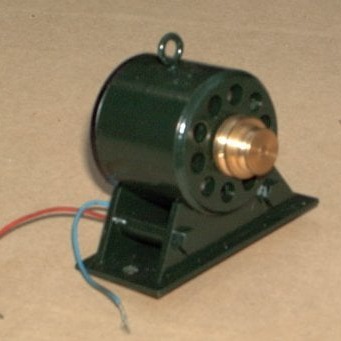

The dynamo for the plant was made from an old tape player motor. The motor was mounted in a housing made from scrap material.

The dynamo was designed to be driven by the engine flywheel and the pulley diameters were calculated to give speeds of 3200 and 4800rpm with the engine running at 800rpm.

The Dynamo was designed to light 2 lamps mounted on the model. There was a tall, floor mounted lamp next to the dynamo and a second lamp mounted on the front of the water tower. The bulbs were 6v grain of wheat bulbs from a model railway and he stands made from off-cuts of hex, round and copper tube.

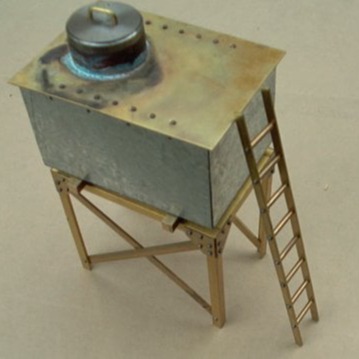

The water tower is shown here before painting.

The underside was fitted with 2 outlets, one for an engine driven pump and one for a manual top-up pump.

An old water gauge was attached to the side of the tank to give a water level reading.

Video of the steam plant in operation.

HTML Website Generator