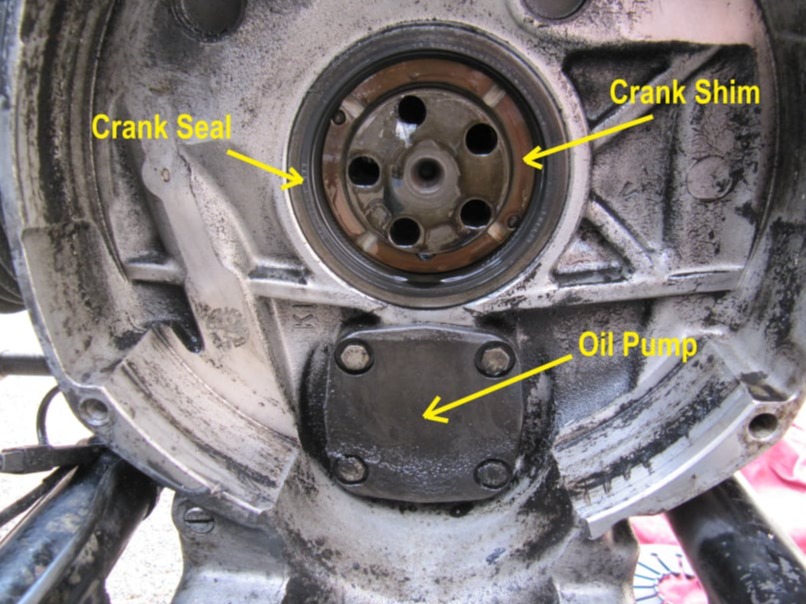

Caution: When the flywheel is removed it is possible for the crank to slide forward and if this happens bearing shims inside the rear engine cover can drop out of place. Refitting the shims is difficult without extensive strip down of the engine and failure to realise the shims have moved can lead to bigger problems. It is, therefore, worth taking steps to ensure the crank cannot slide forward.

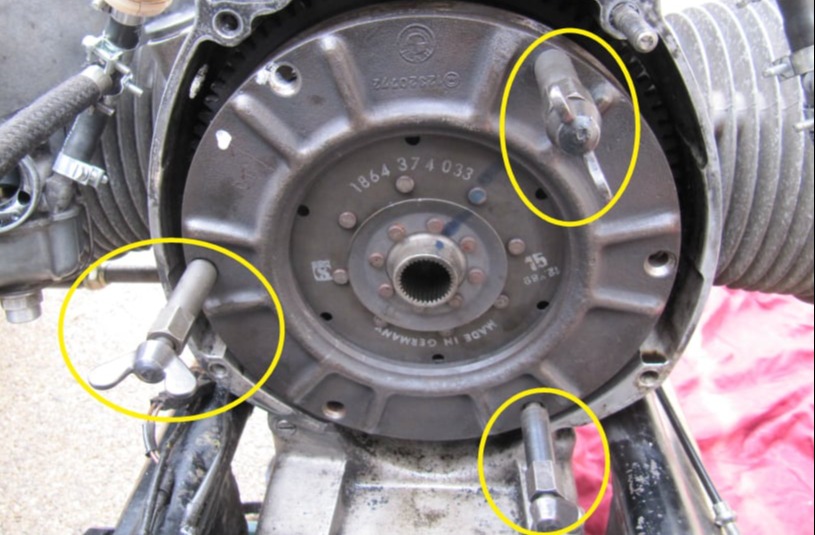

To prevent crank movement, the engine front cover should be removed and a block of wood and a ratchet strap used as shown. The wood should be positioned to press on the end of the alternator bolt.

Only moderate tension of the strap is required.

Warning: The Battery should be disconnected before removing the engine front cover. It is all too easy to cause a short on the regulator board by touching it with the cover which can cause expensive damage.