BMW Tools

The standard BMW tool kit comes with a multitude of tools.

Some of them are quite specific and make maintenance of the bike much easier.

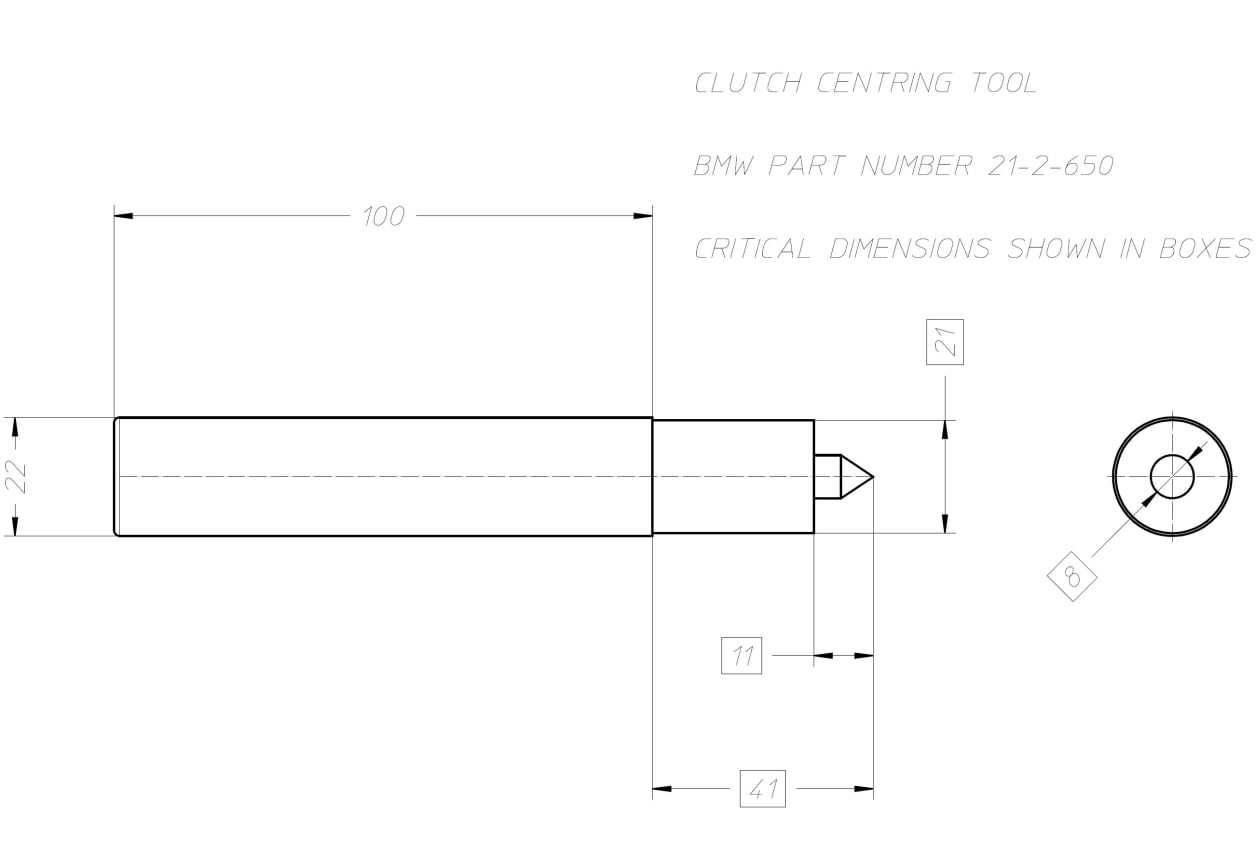

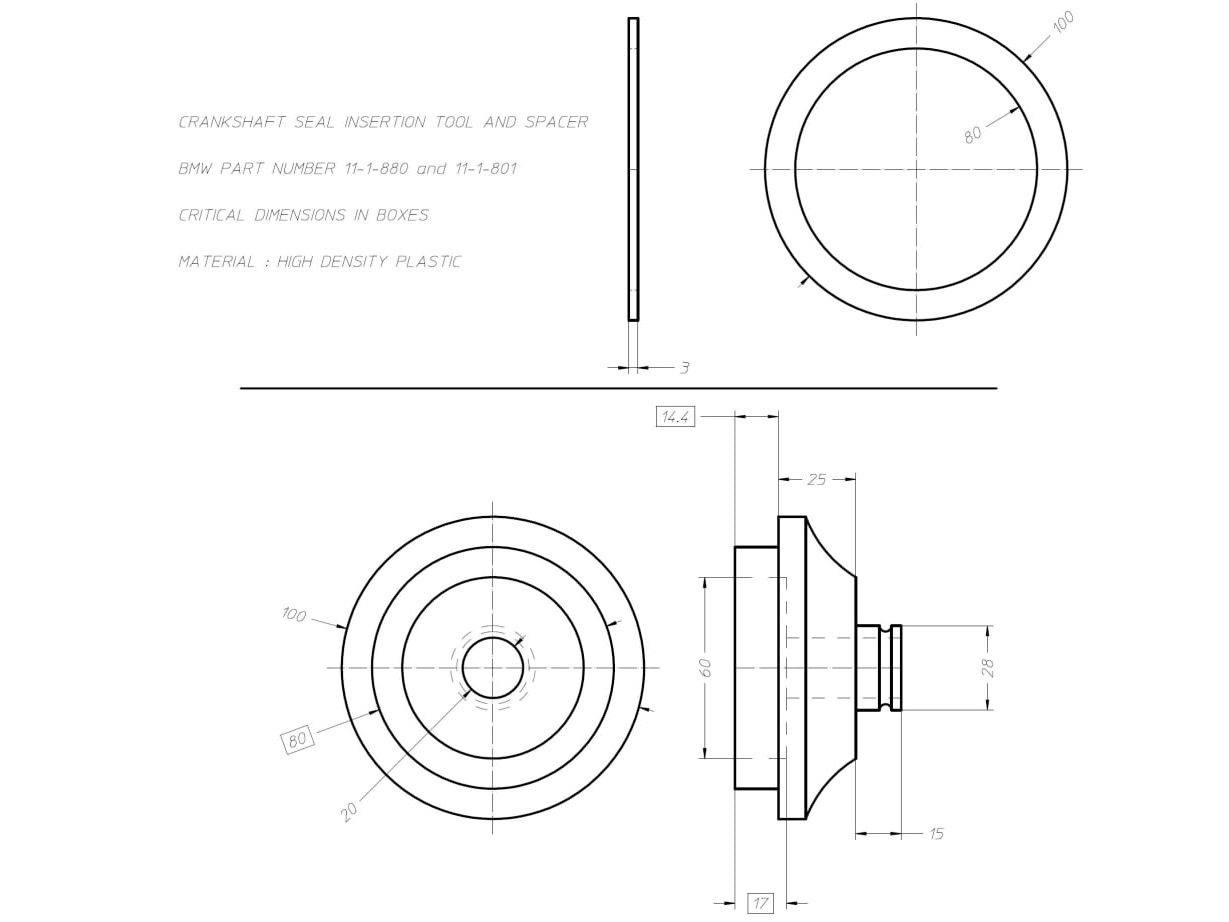

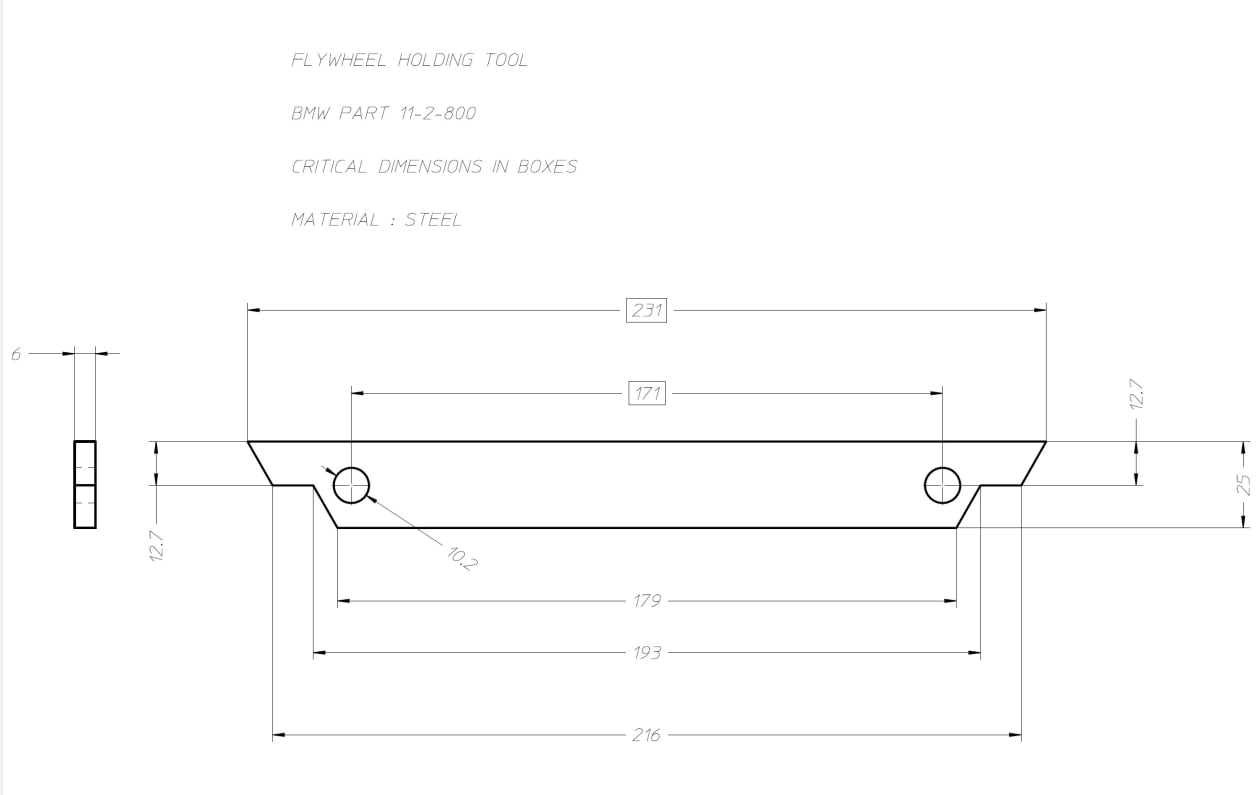

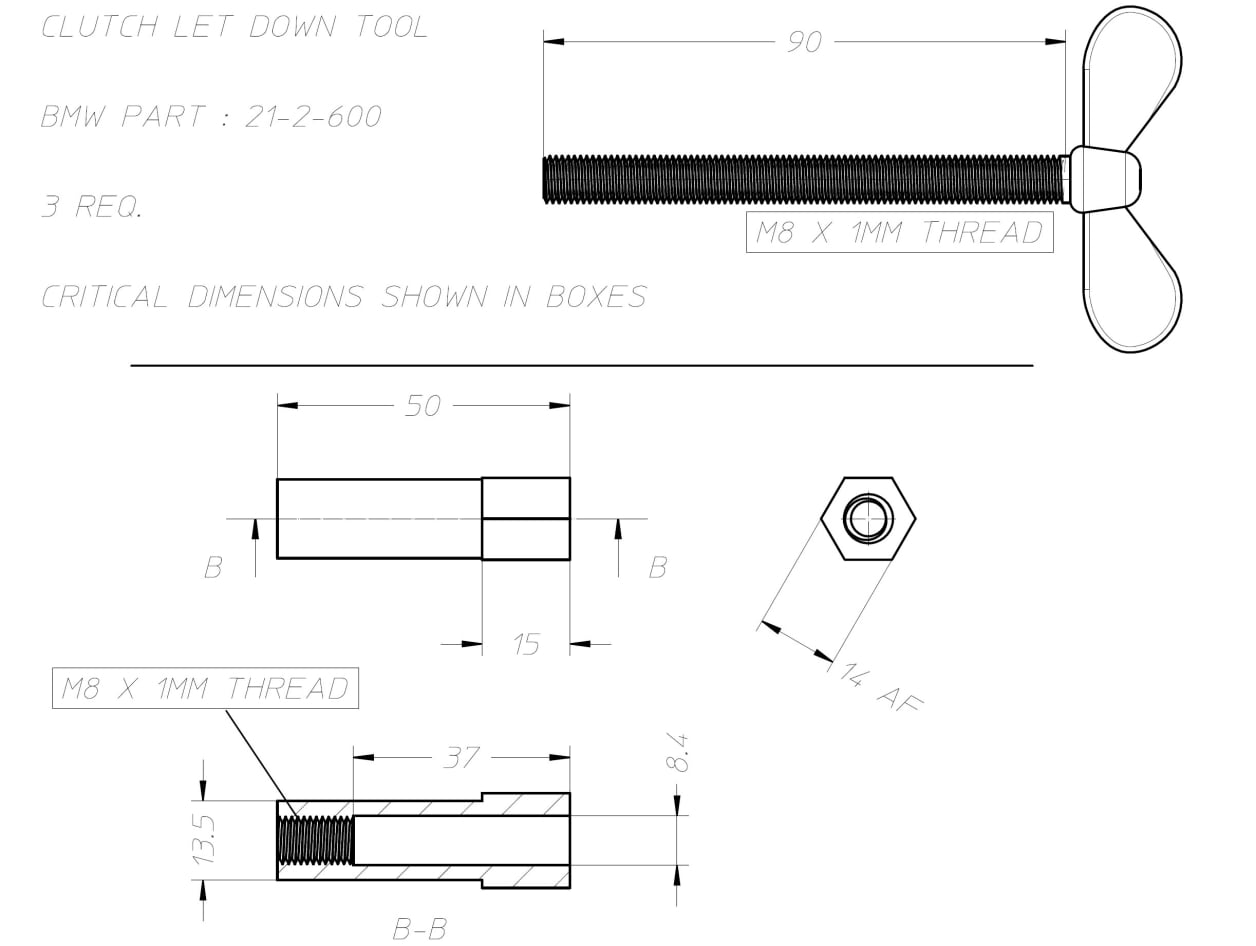

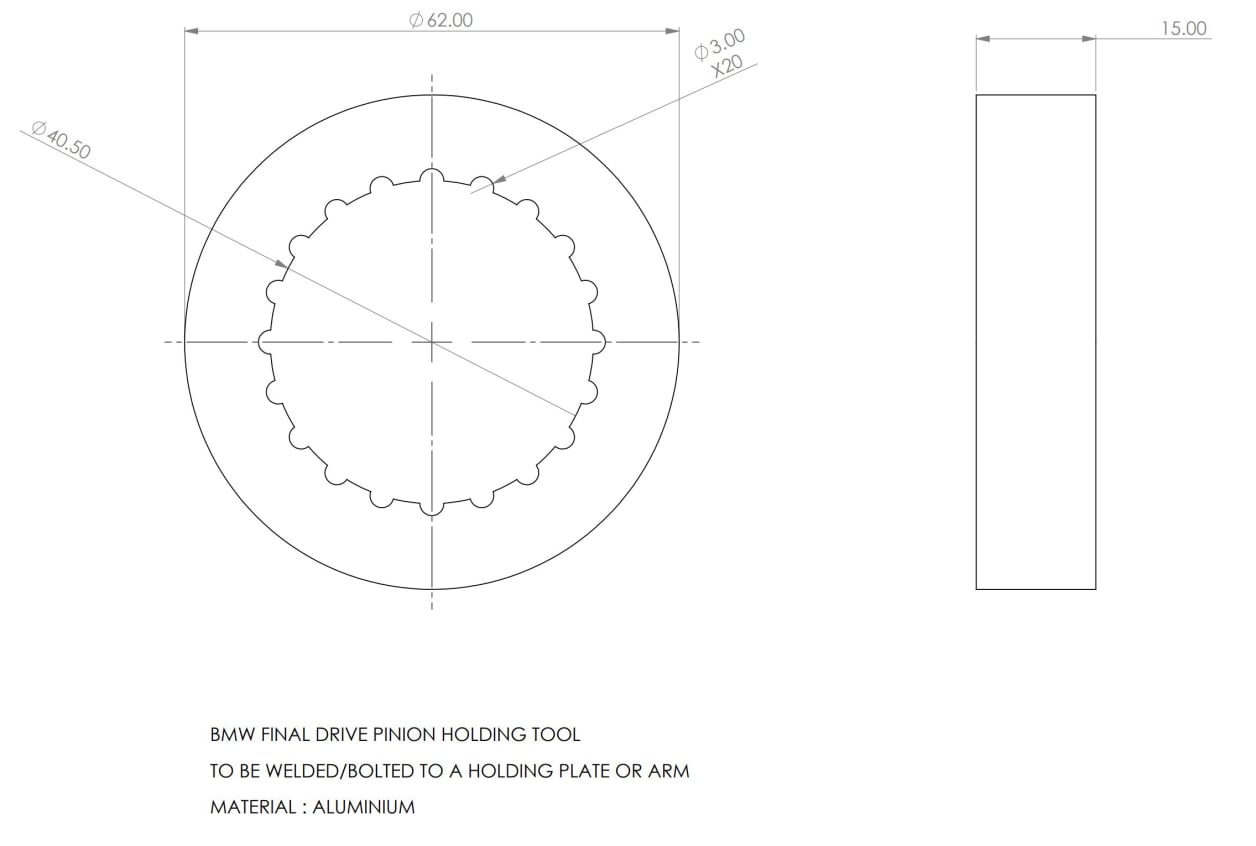

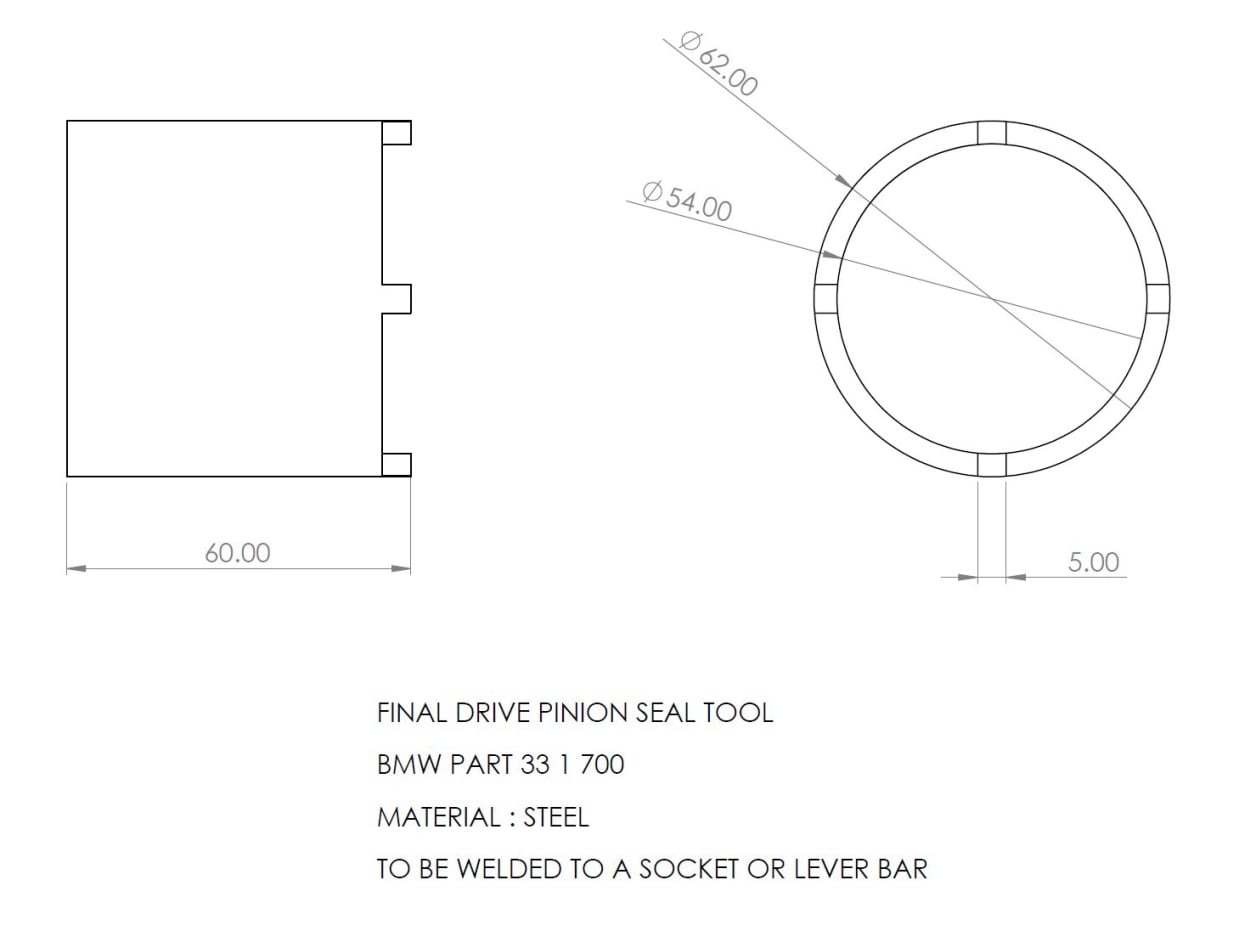

Here are some home made equivalent tools in case they are missing from your kit.

There are also some drawings for official BMW workshop tools.