Using a Sine Bar

A sine bar is a precision fixture for holding work at specific angles.

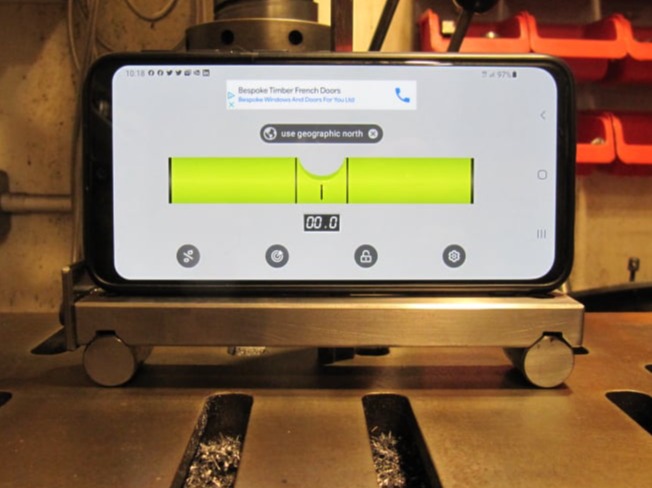

It can be used in the milling vice to produce an angled face or add a chamber to an edge. It can also be used to drill holes at specific angles.

The sine bar used in this case was a 5" one, which is exactly 127mm.

This distance is the measurement between the centre of the two cylinders on the bar.