Lathe Techniques

The page documents some processes to follow to create simple but accurate features and components.

There are 3 basic operations which cover many of the tasks done on the lathe.

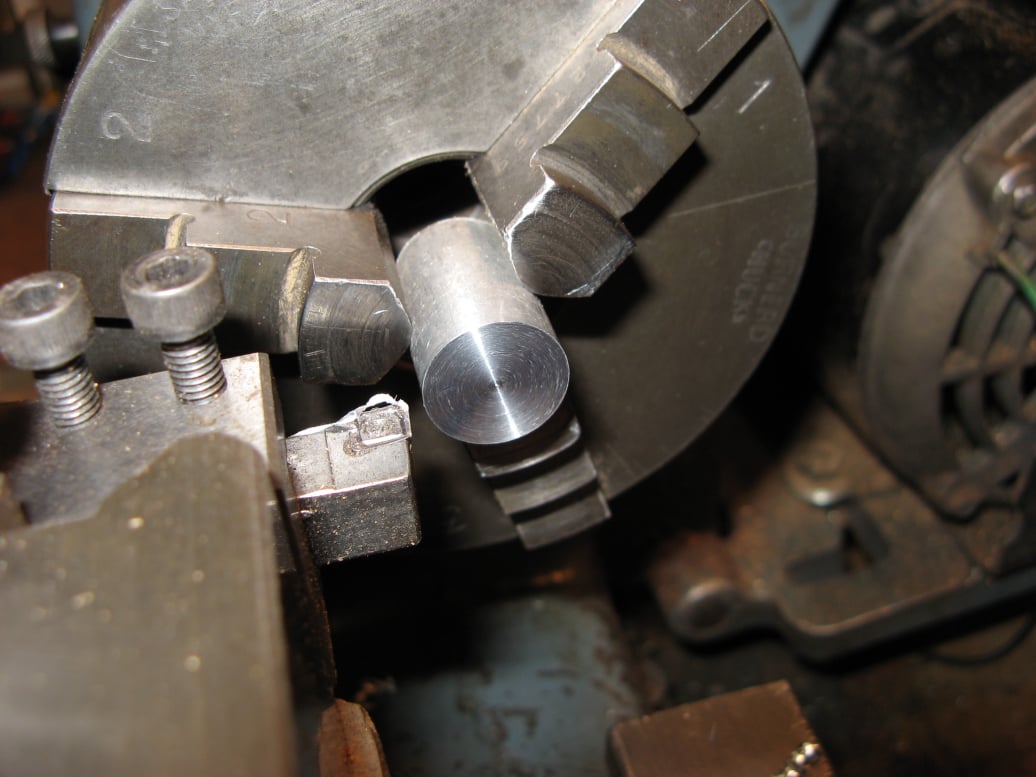

Turning a bar to length

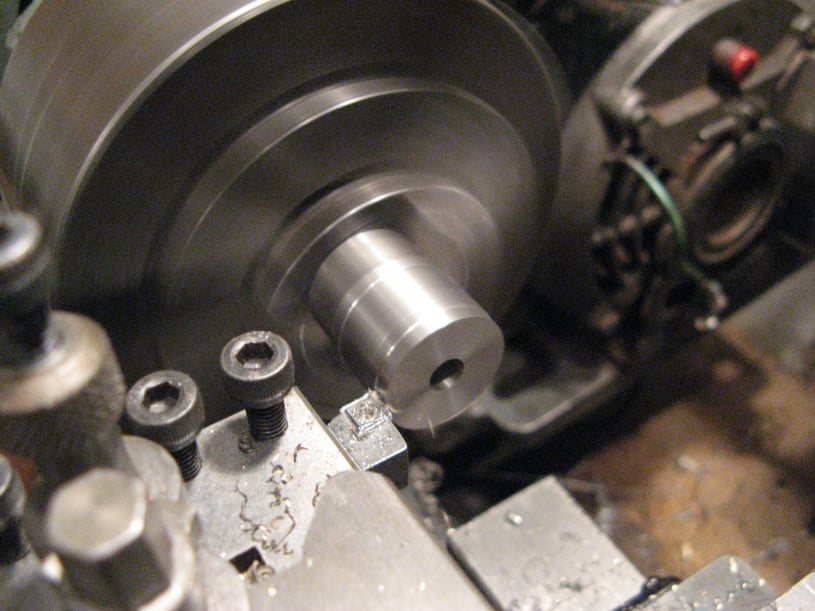

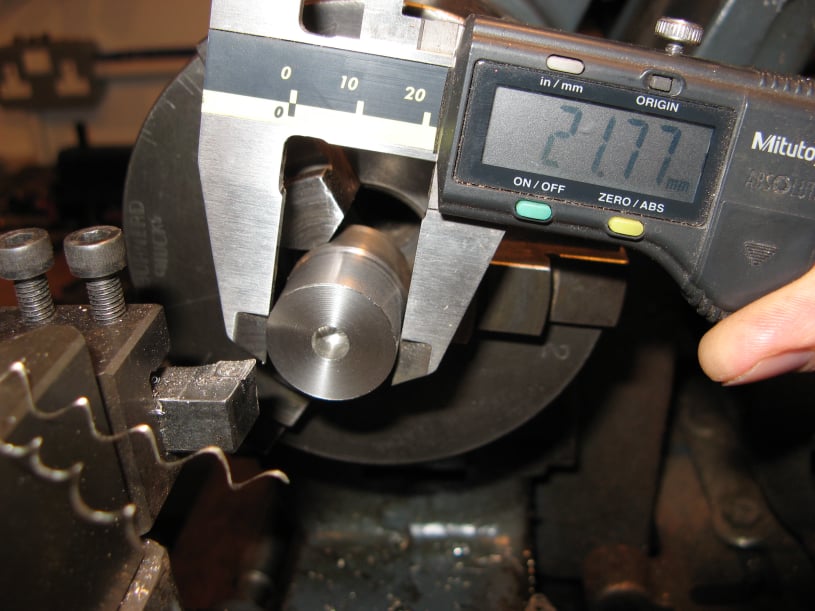

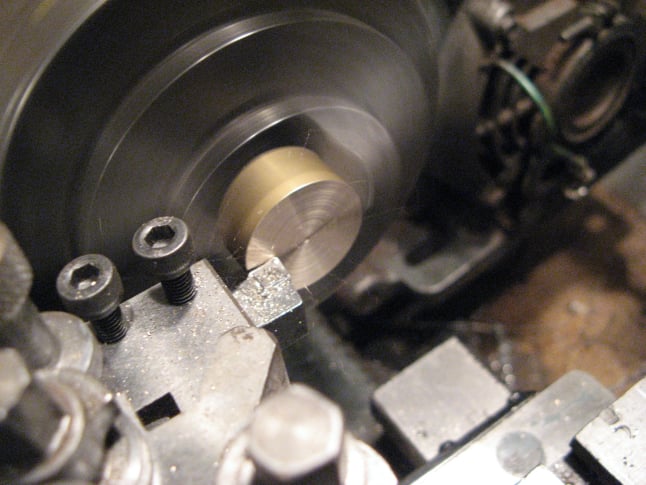

Turning to a required diameter

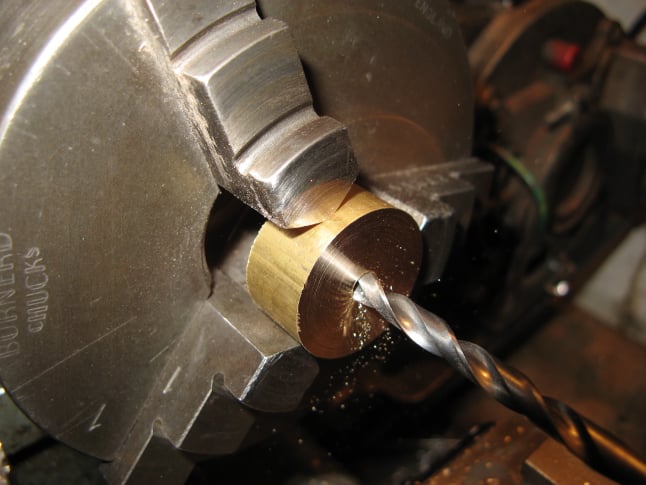

Drilling a hole using the tailstock