The MK1 Steam Engine

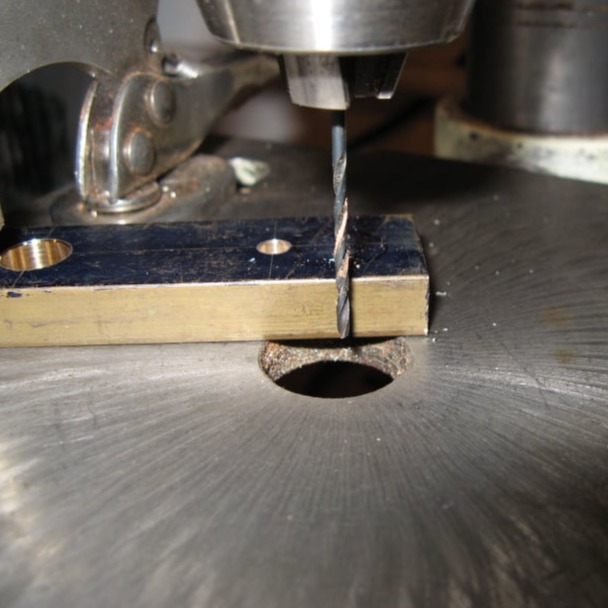

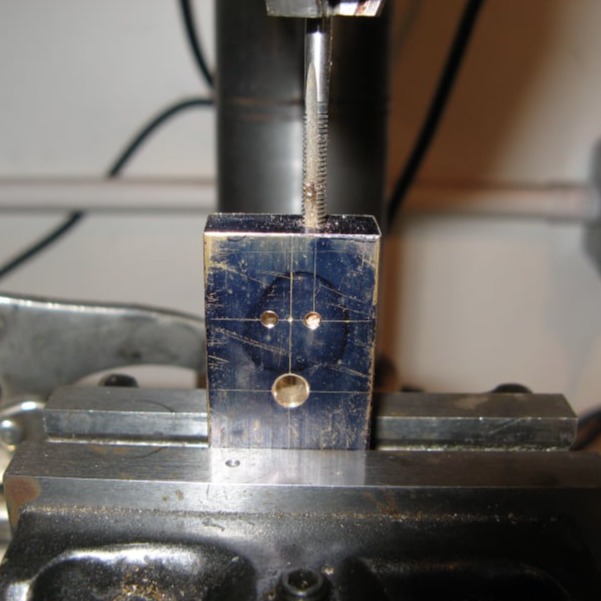

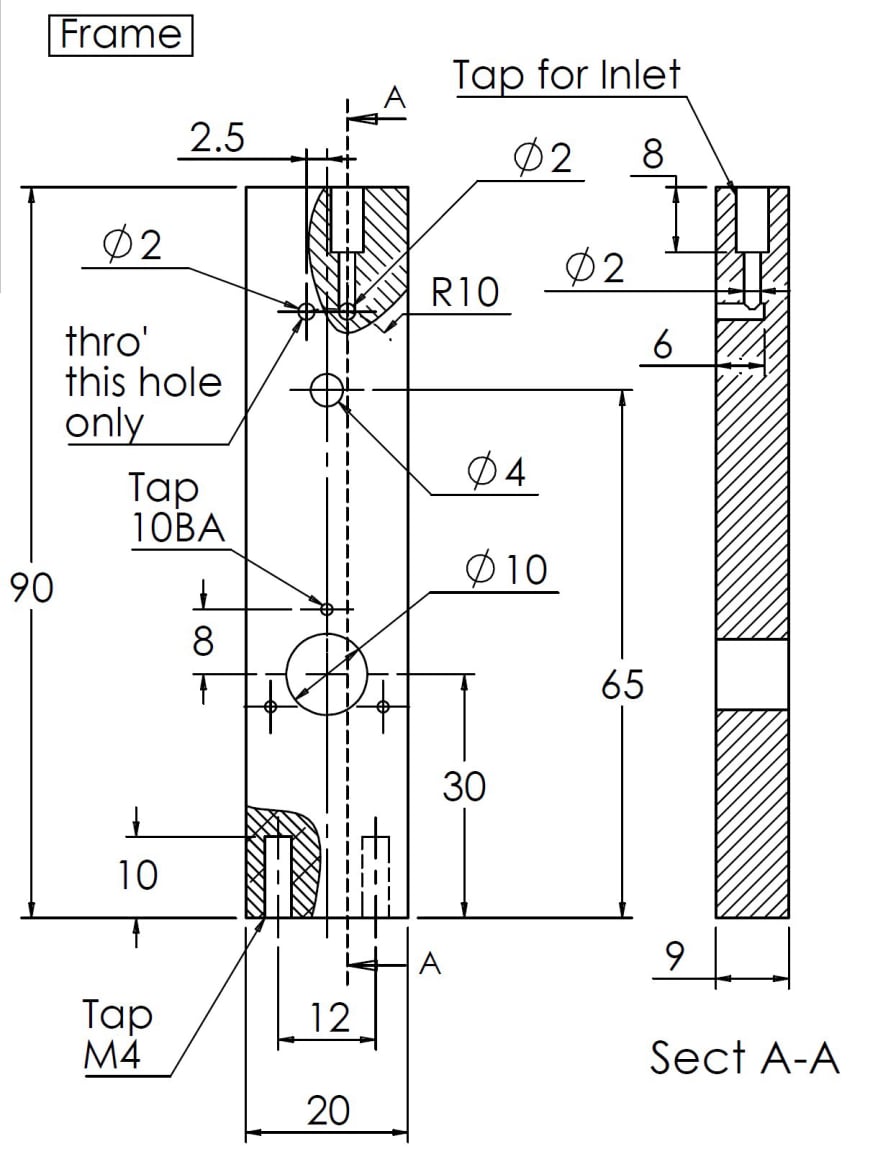

Frame

The frame is made from a thick piece of Brass bar. The plans call for something about 9mm thick and 20mm wide and 90mm tall.

The thickness can be a few millimetres either way, as long as the bearing shoulder length is adjusted to suit.