Stuart Victoria

The Eccentric and Strap

The eccentric strap was machined first and then the eccentric itself was machined to be a close running fit in the strap.

The eccentric strap was machined first and then the eccentric itself was machined to be a close running fit in the strap.

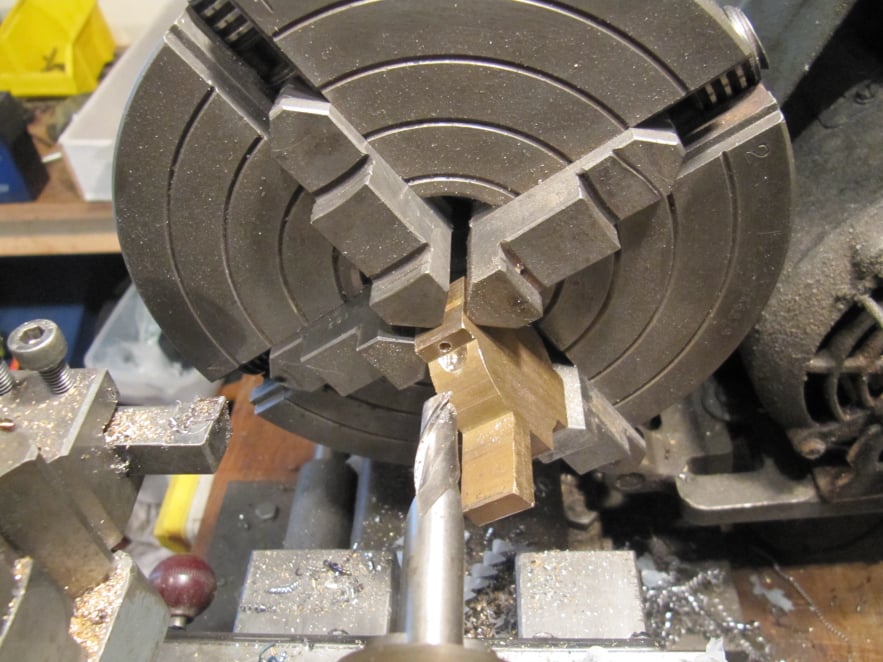

The holes to take the clamping screws were drilled first using the 4-jaw chuck to ensure the holes were square to the sides of the part.

Each hole was marked with a centre punch to enable centring in the chuck. Then the holes were centre drilled and drilled. Finally an end mill was used to add some clearance around the bolt head.

The strap part was sliced along the mark provided using a slitting saw in the milling machine.

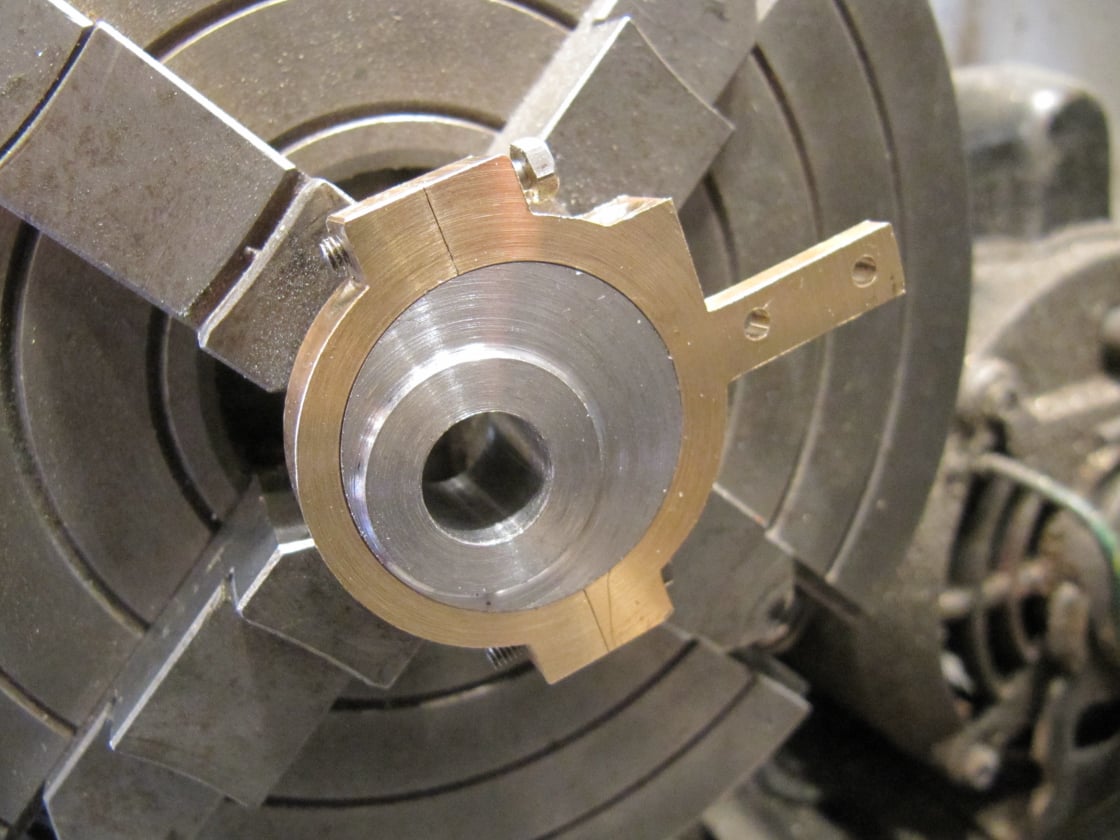

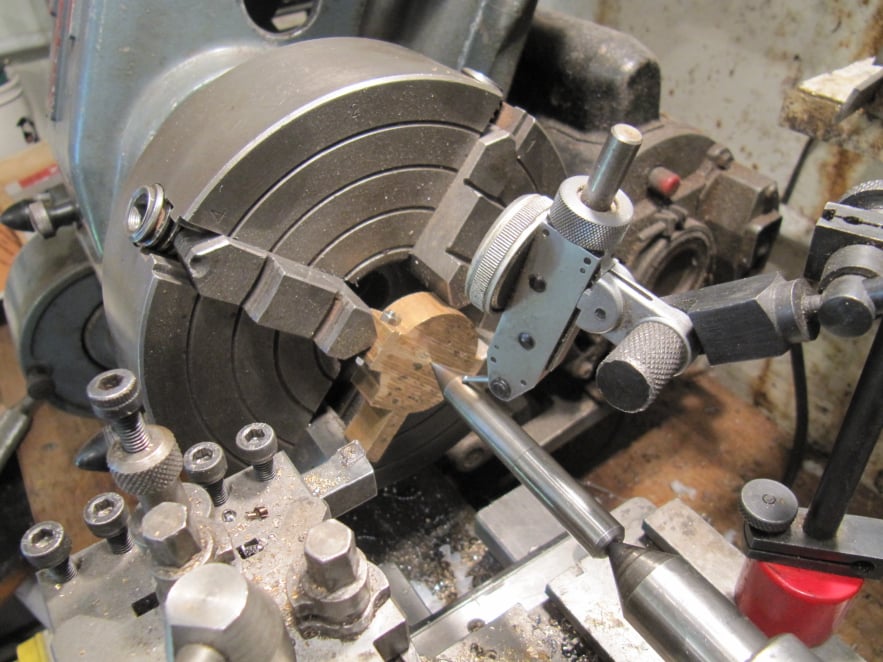

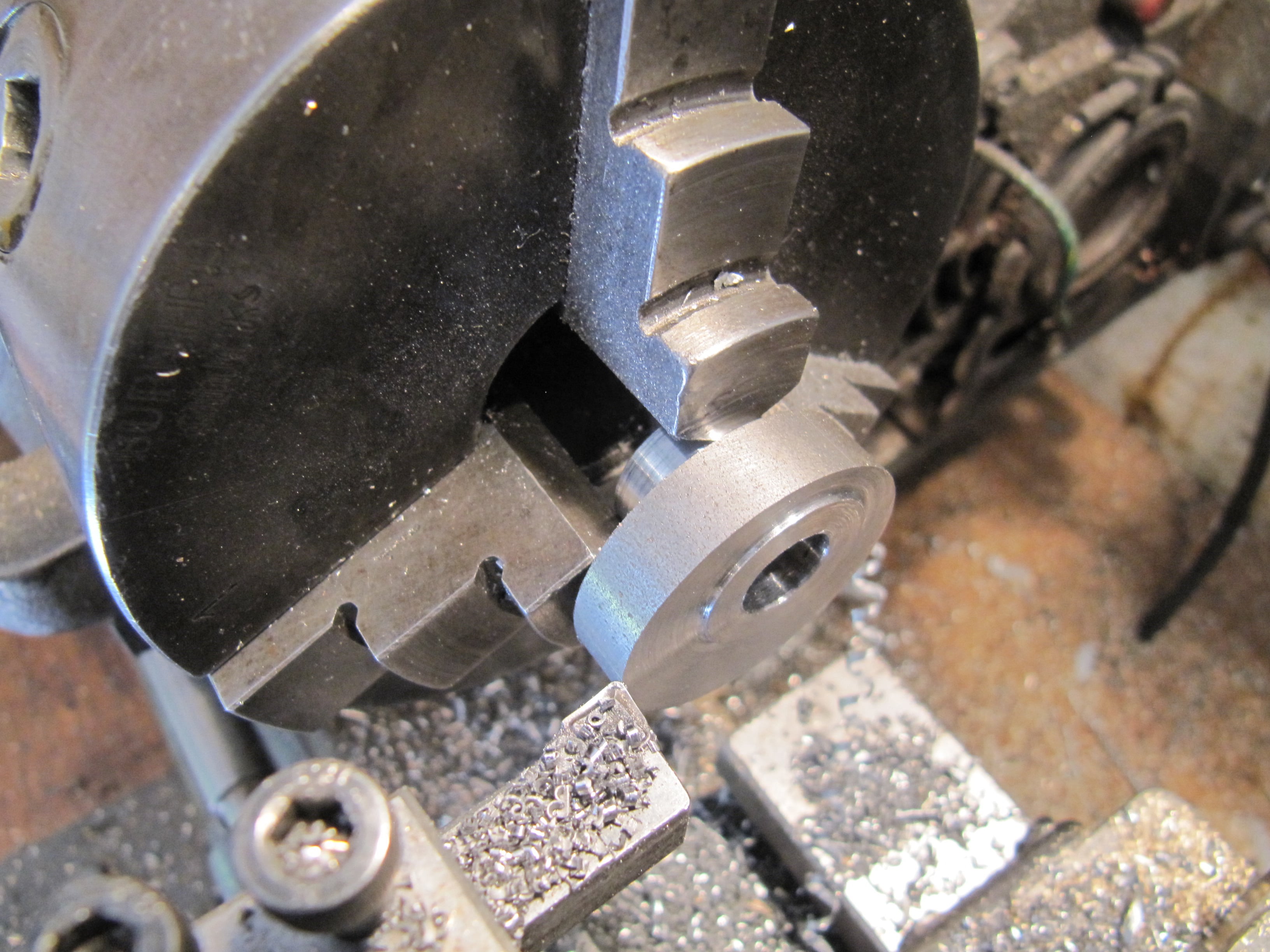

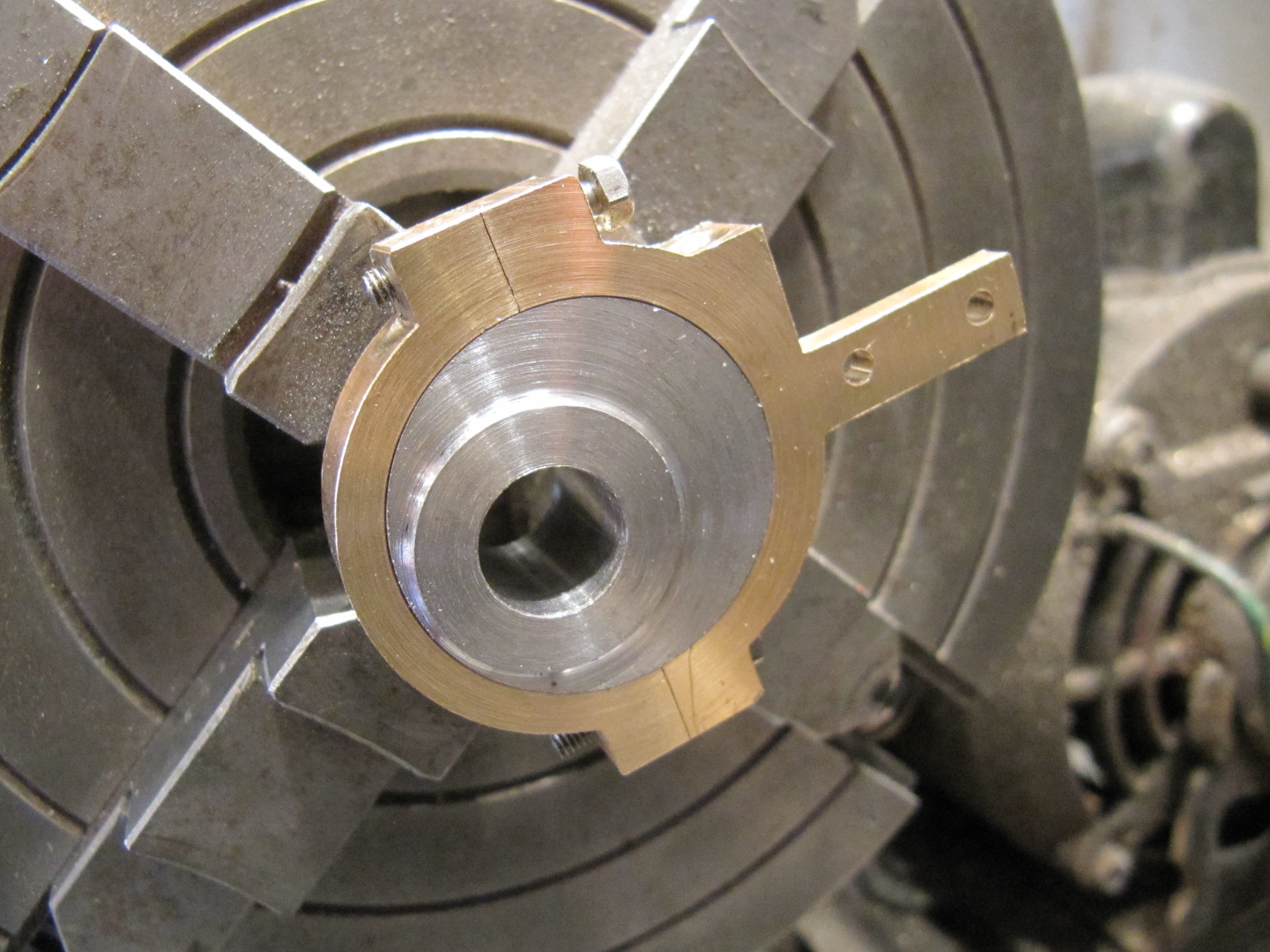

With the two halves bolted back together the centre was marked and the part was mounted in the 4 jaw chuck.

It was centred about the mark and checked to ensure it was upright and level in the chuck jaws.

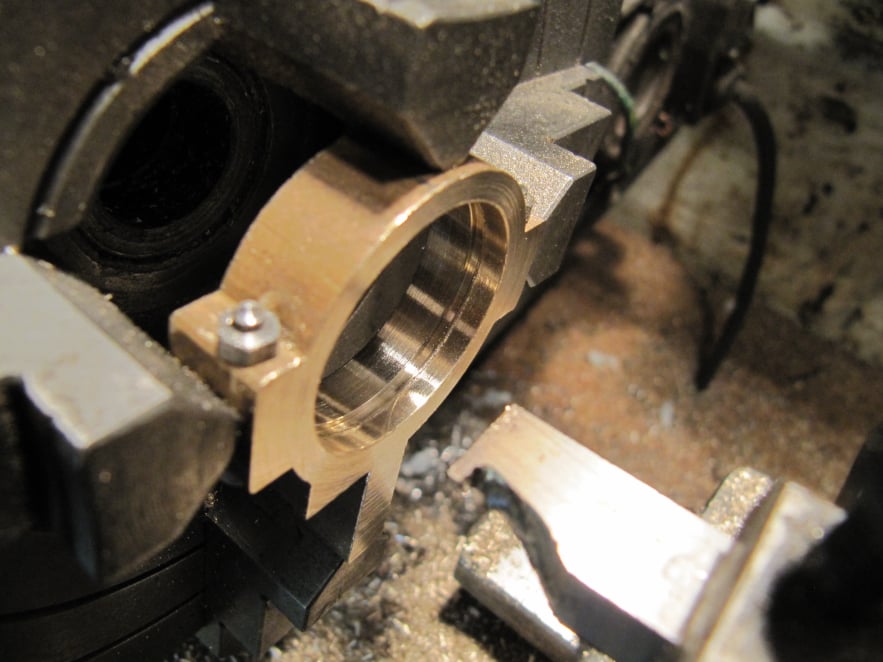

In this setting the part was bored to final size using a boring bar and half the excess thickness removed.

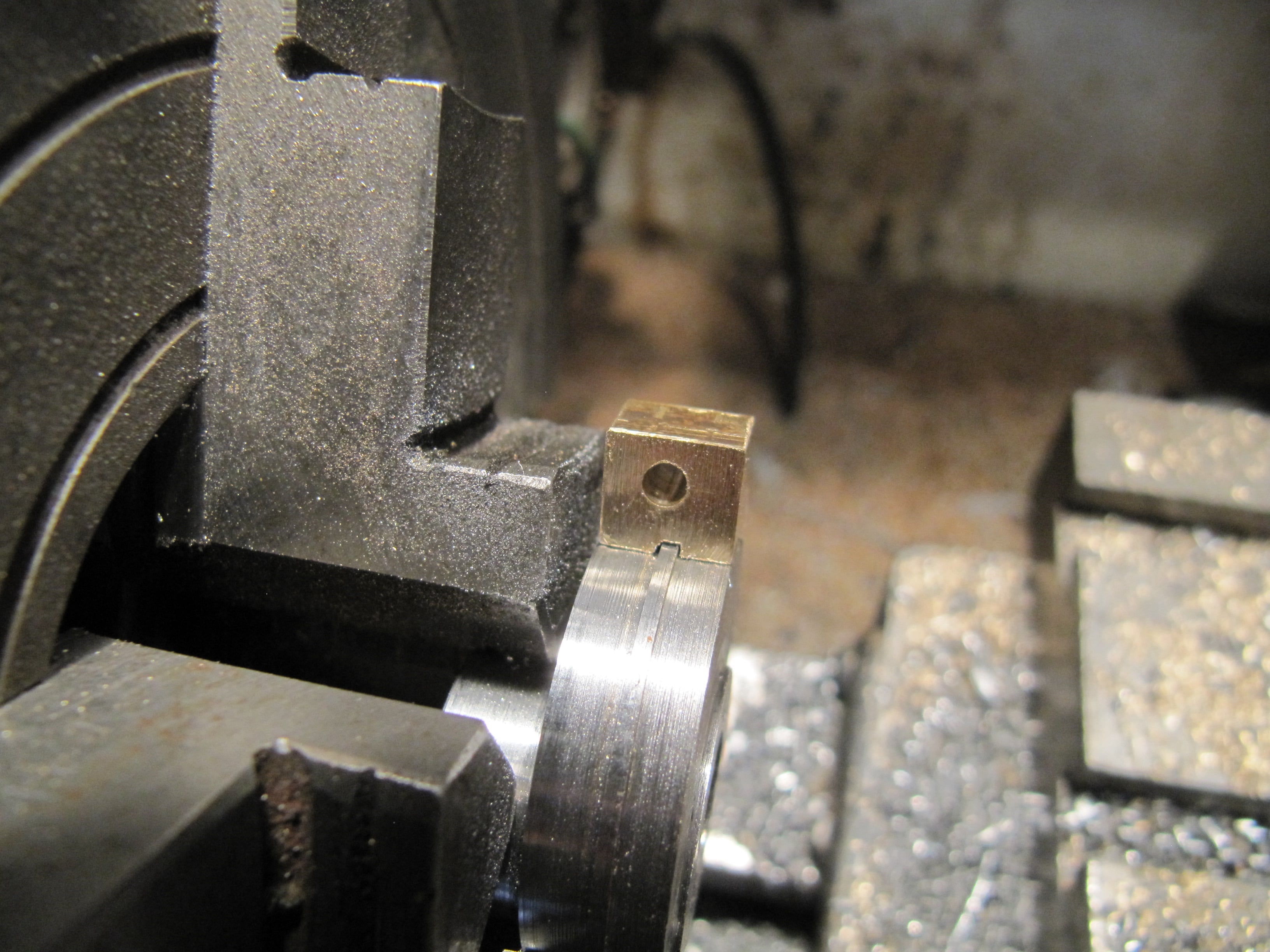

A custom ground tool was then used to add the locating groove on the inside.

The part was reversed in the chuck and set to run without any wobble so that it could then be machined to final thickness.

The milling machine was used to reduce the mounting tab to thickness.

Also an oil hole was added on the drill press. Although not shown by the plans it would be a useful addition and would give the square shoulder of the part a purpose as well.

The eccentric was machined using the strap as a guide.

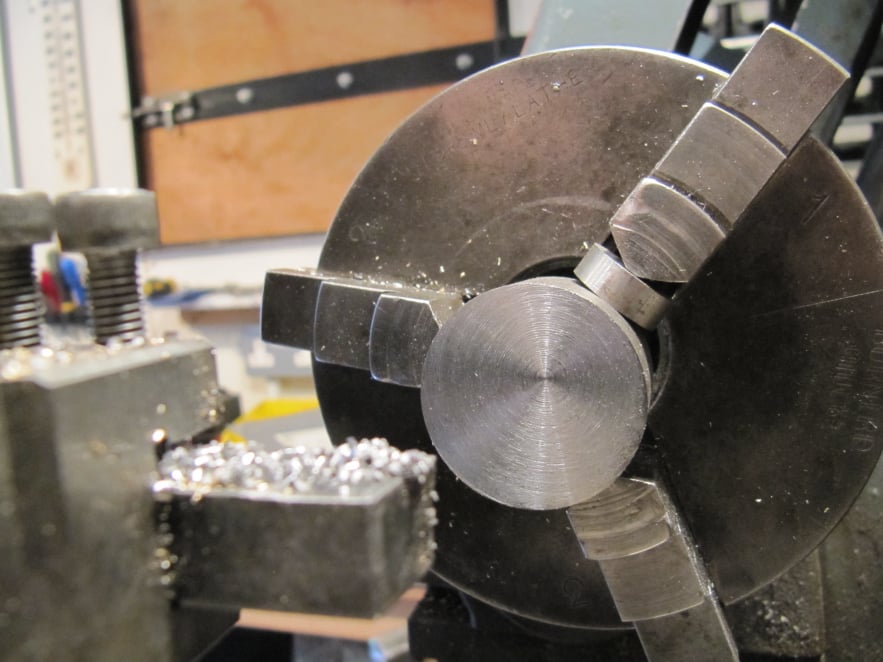

The blank was held in the 3 jaw chuck with a suitable piece of packing to give the required off-set.

The calculations for the packing thickness are given here but in short the required meant was for a x.xxpiece.

In this setting the axle hole was drilled and reamed, and the shoulder was added.

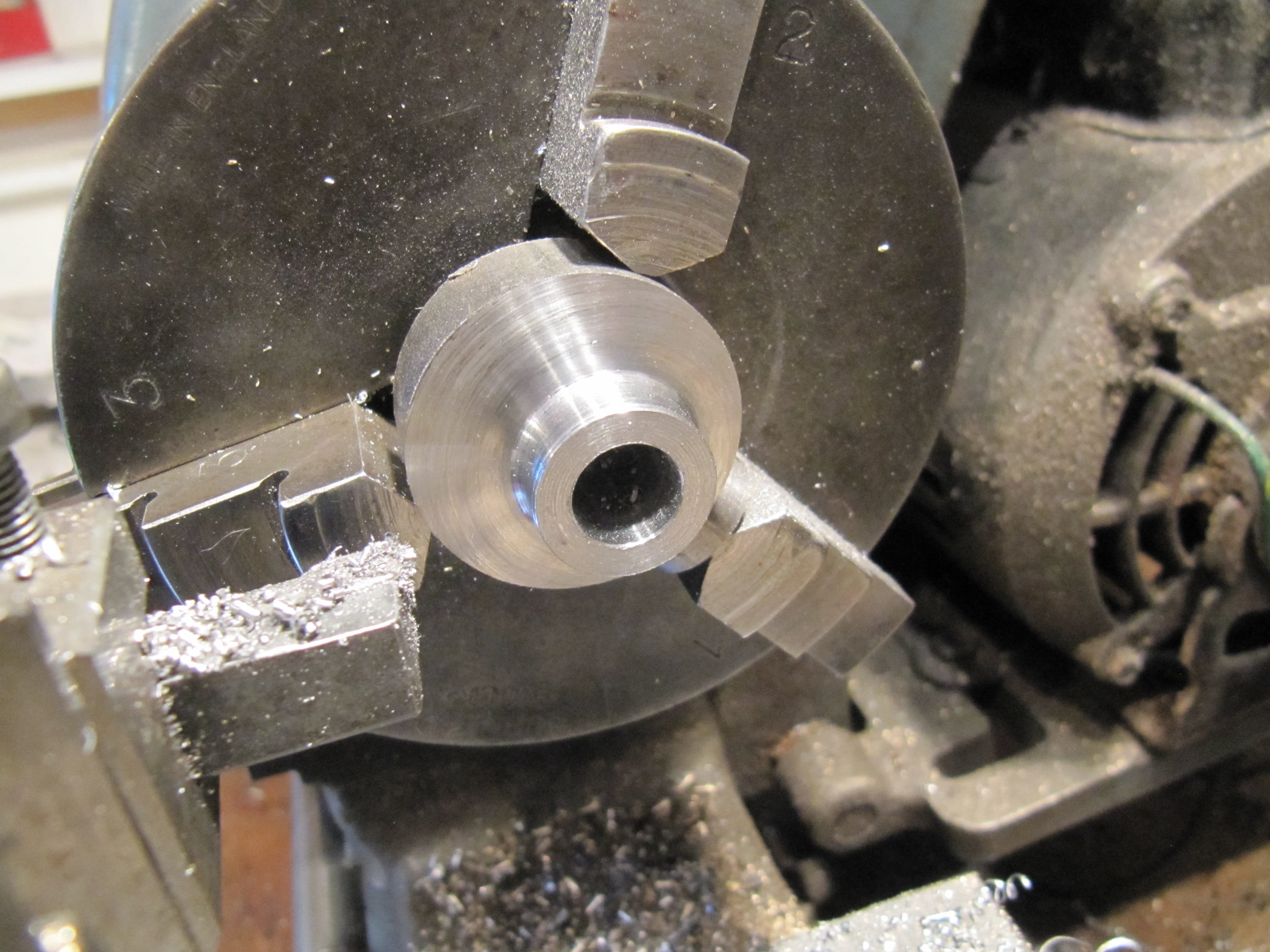

Then the part was reversed in the 3-jaw chuck without packing, to machine a machine a slim clearance shoulder on the other side.

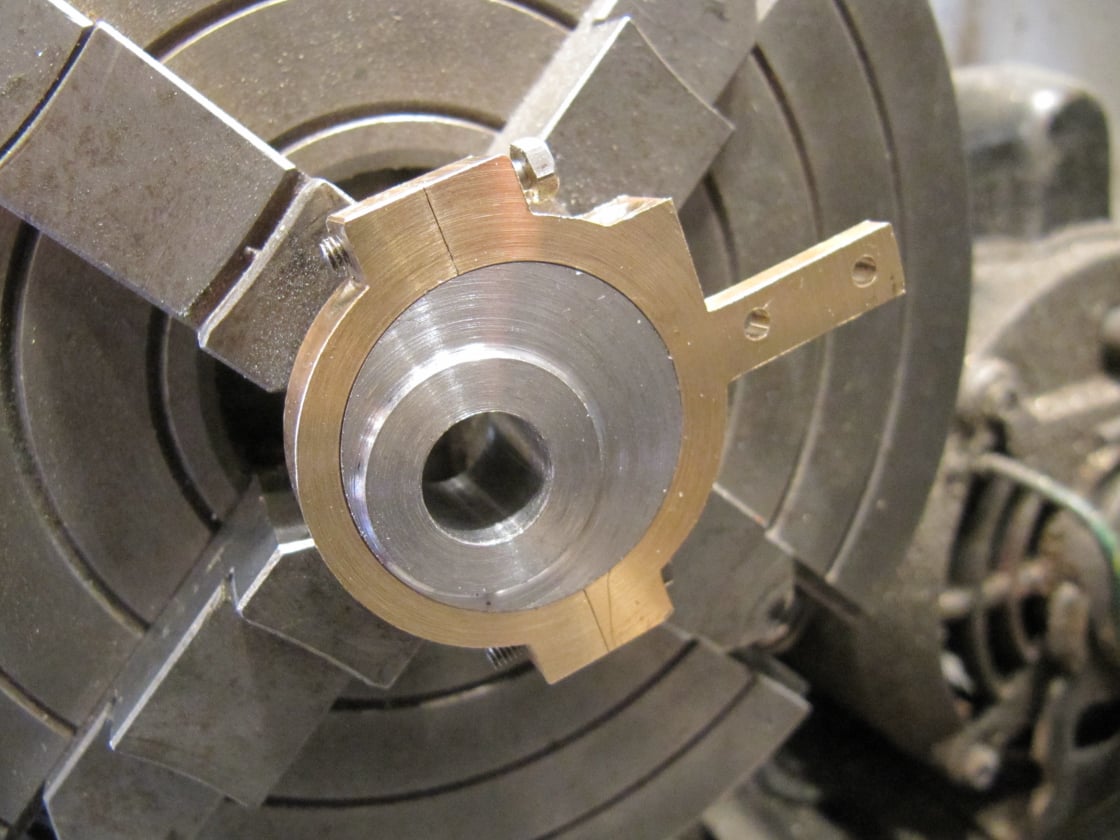

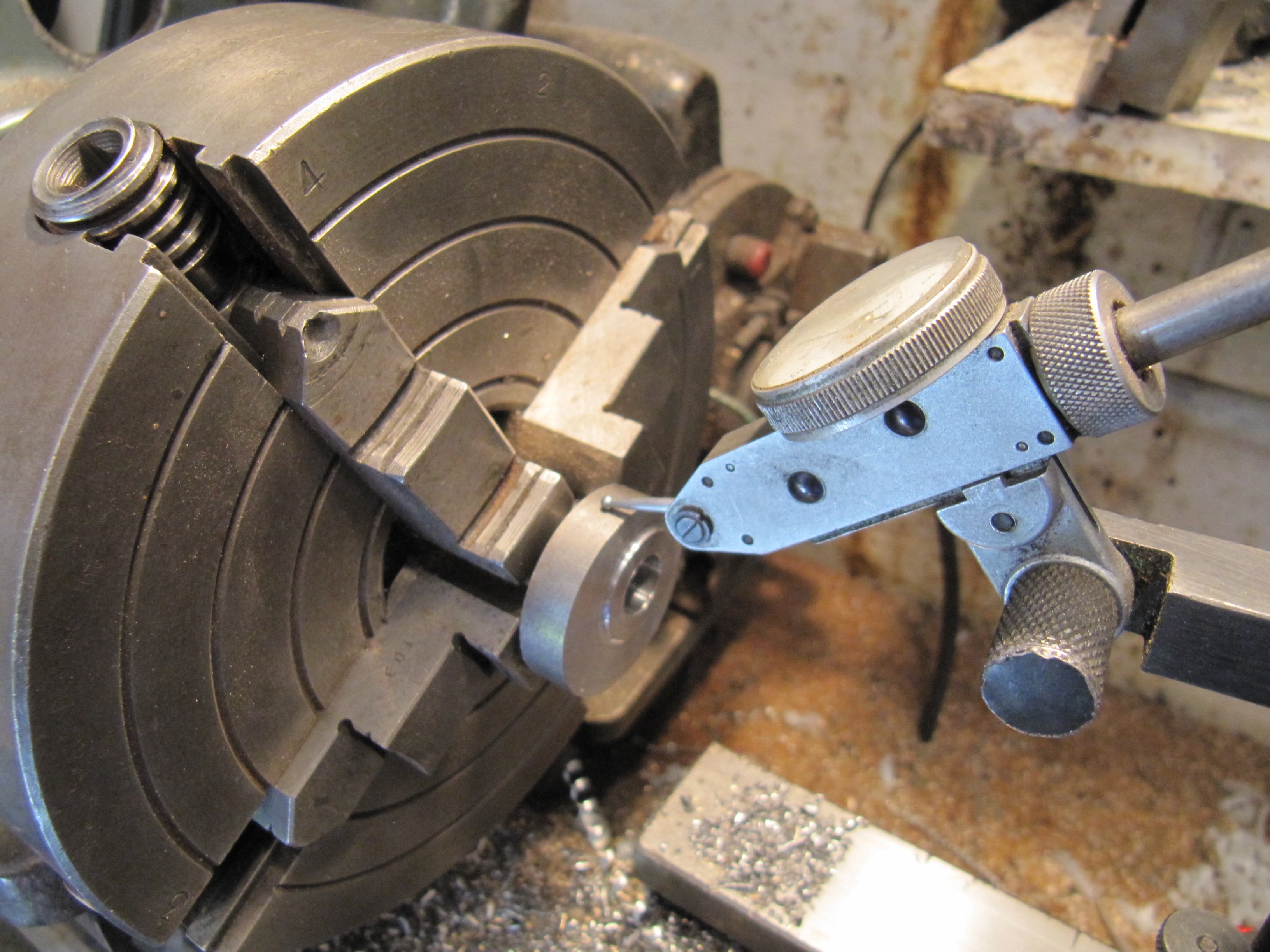

The eccentric was mounted in the 4-jaw chuck held by the large shouldered section; and the outer surface was clocked to run true.

A turning tool and parting off tool was used to create a raised flange that would match the groove cut into the eccentric strap. This raised lip could be shorter than the depth of the groove in the strap, but not so narrow that the strap would wonder when running.

Before removing the part from the chuck the eccentric was fully assembled with the clamp bolts to check for a free running fit.

Best AI Website Creator