Stuart Victoria

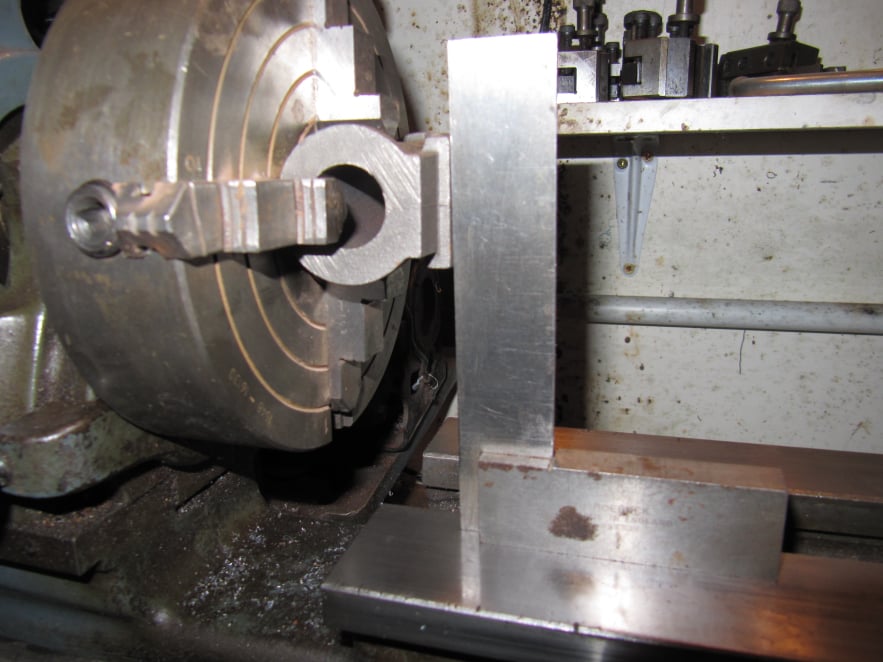

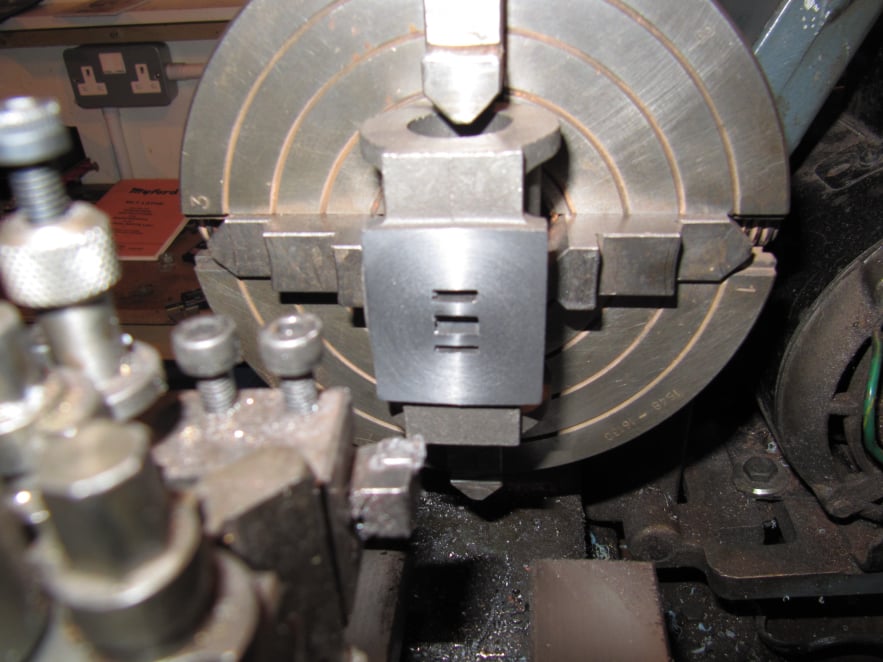

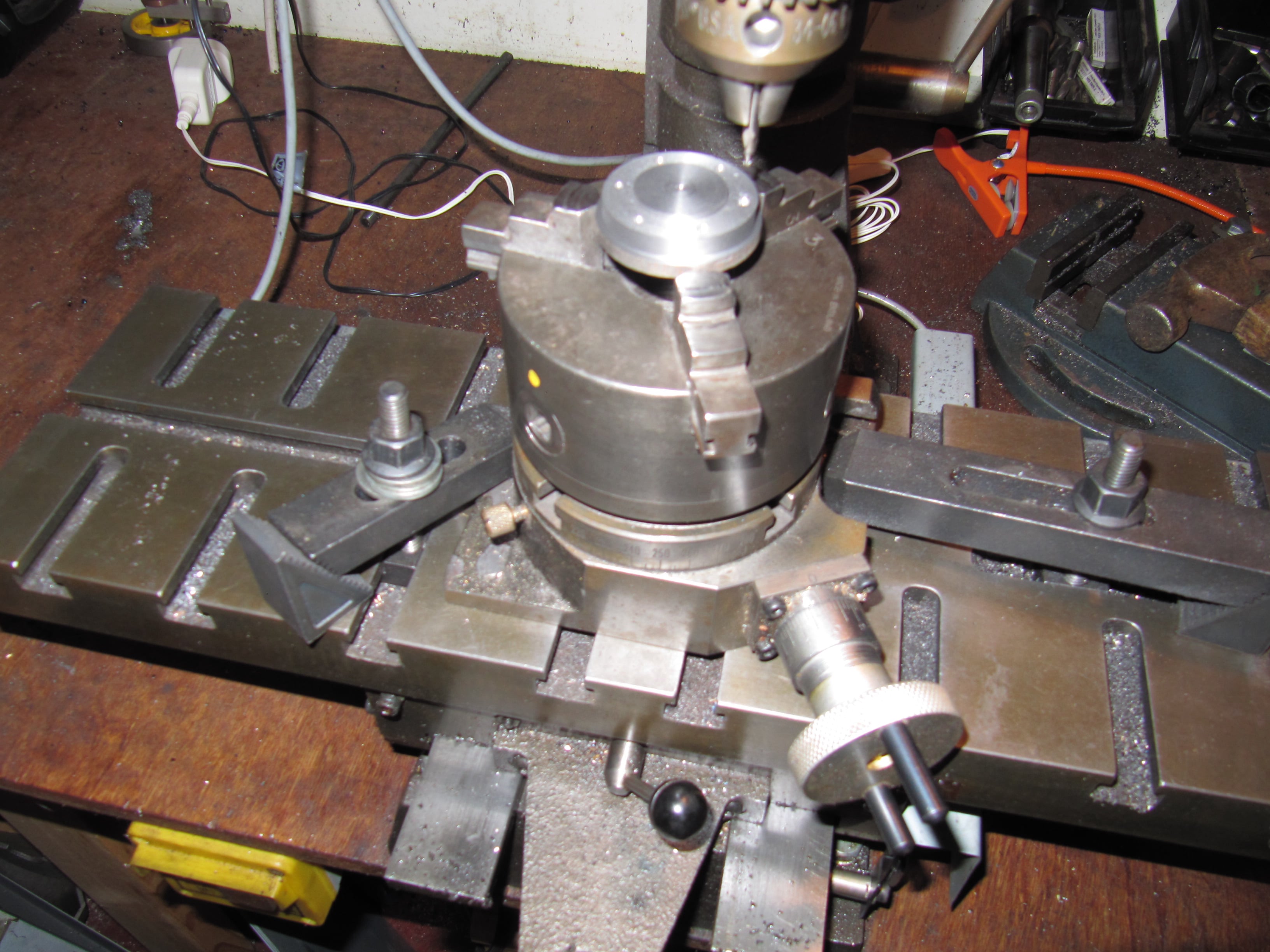

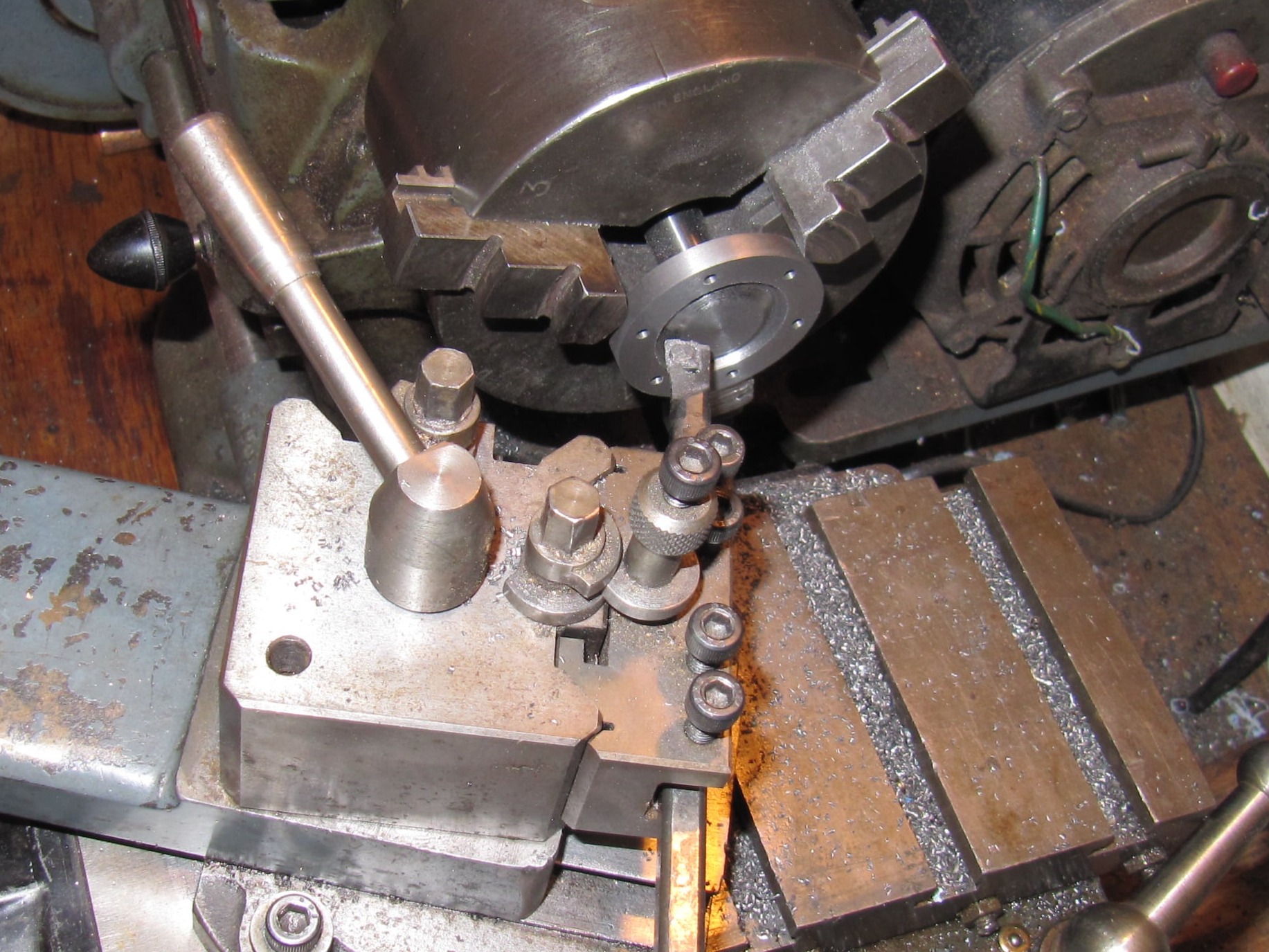

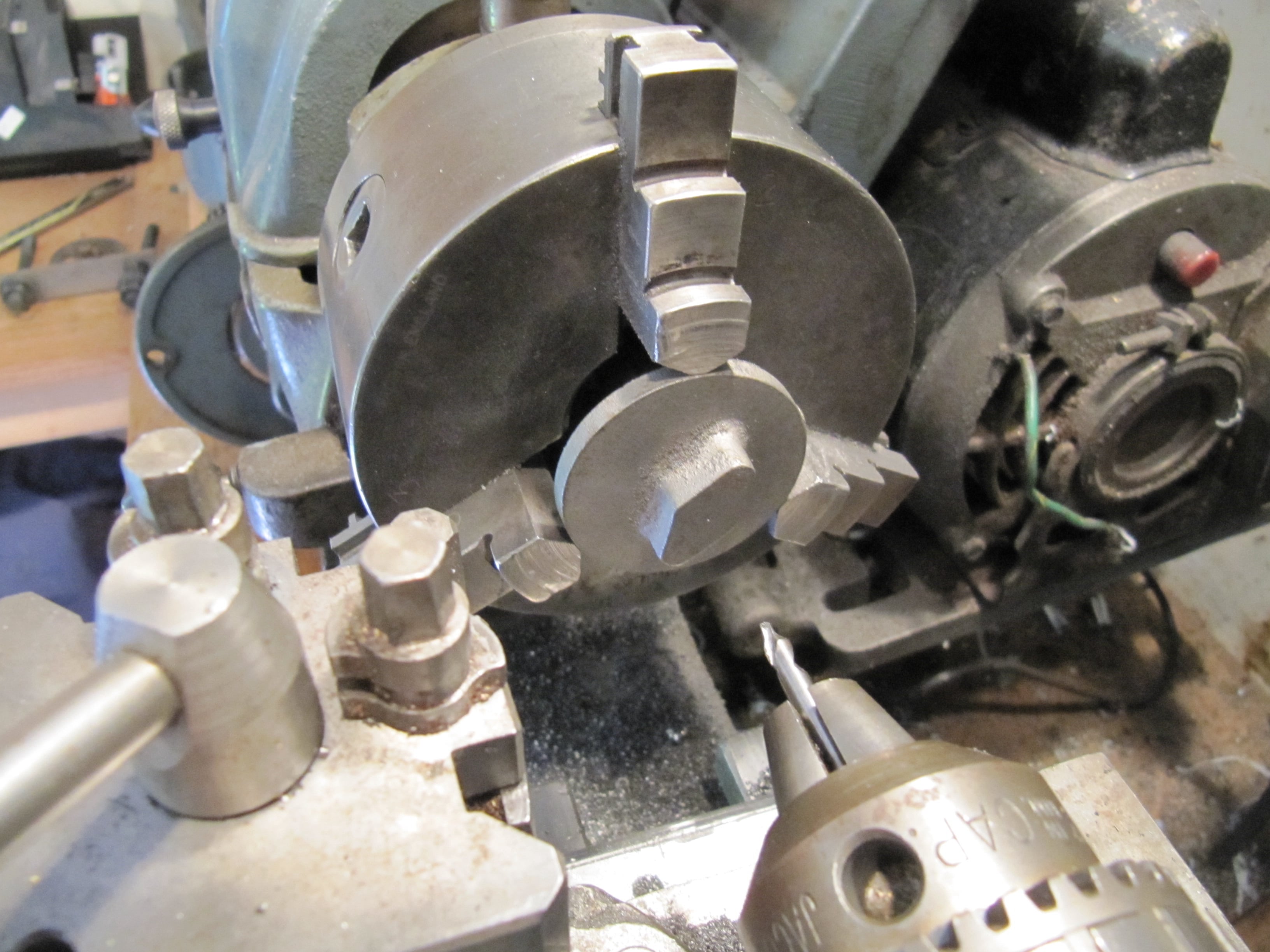

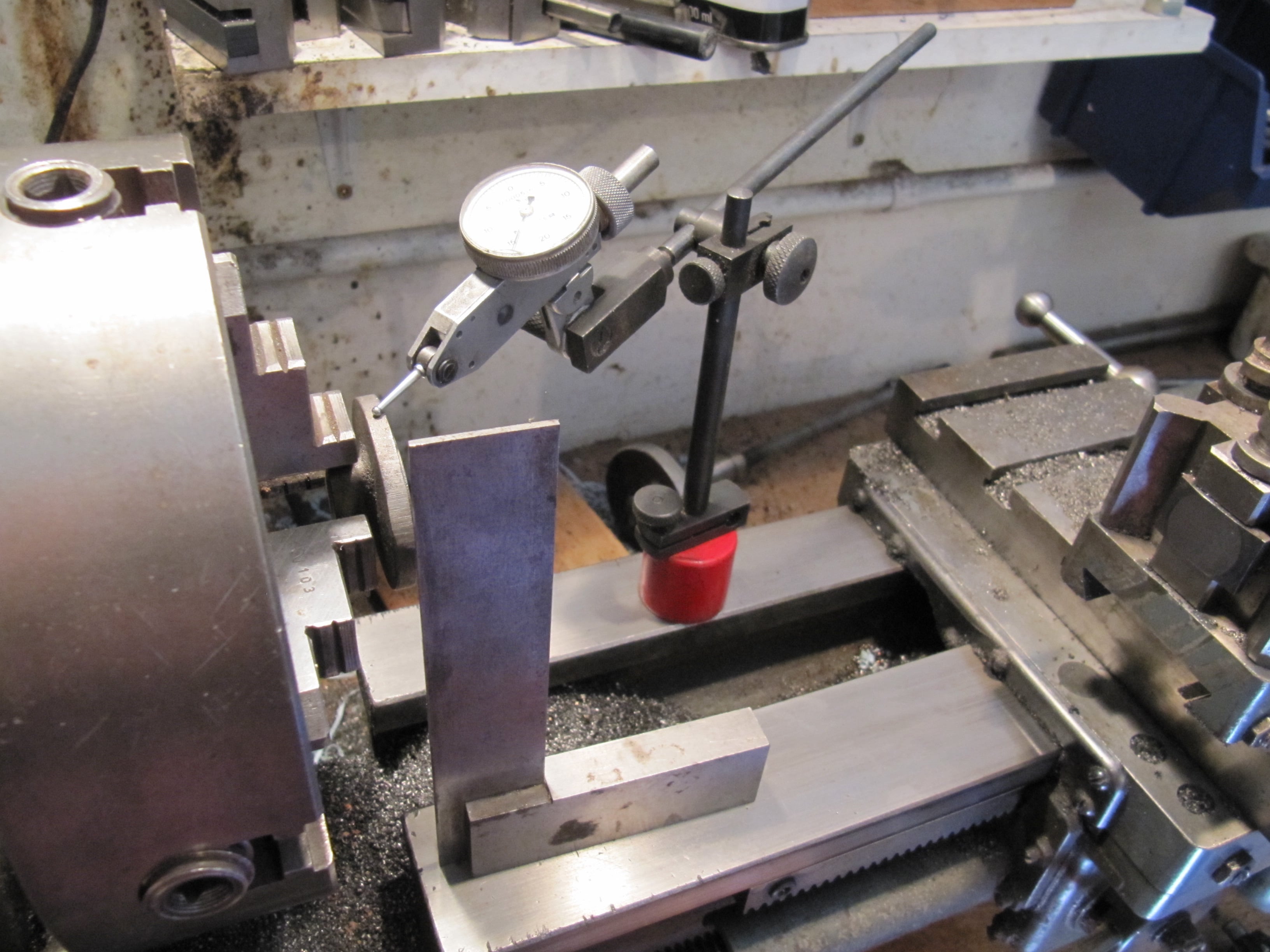

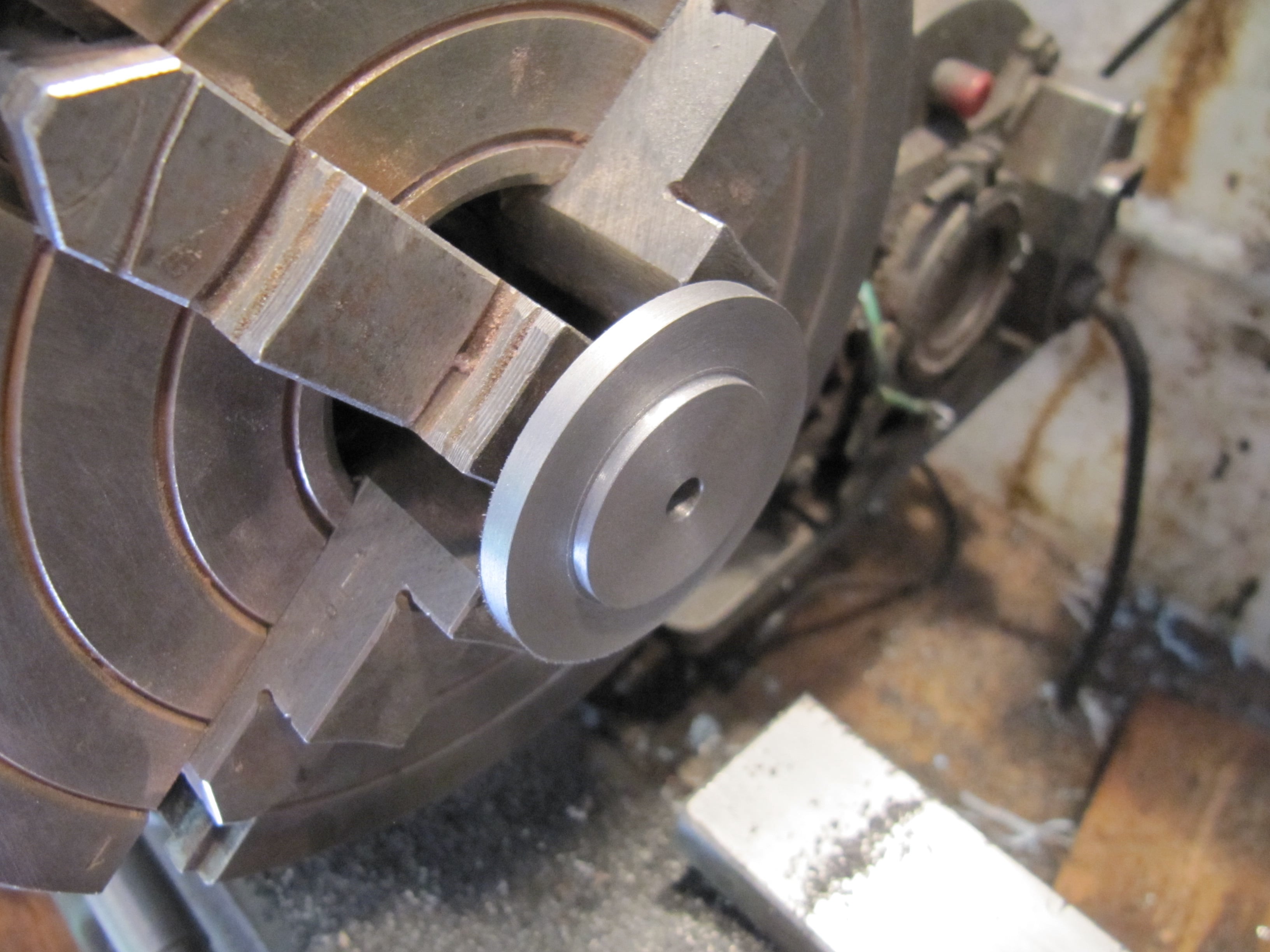

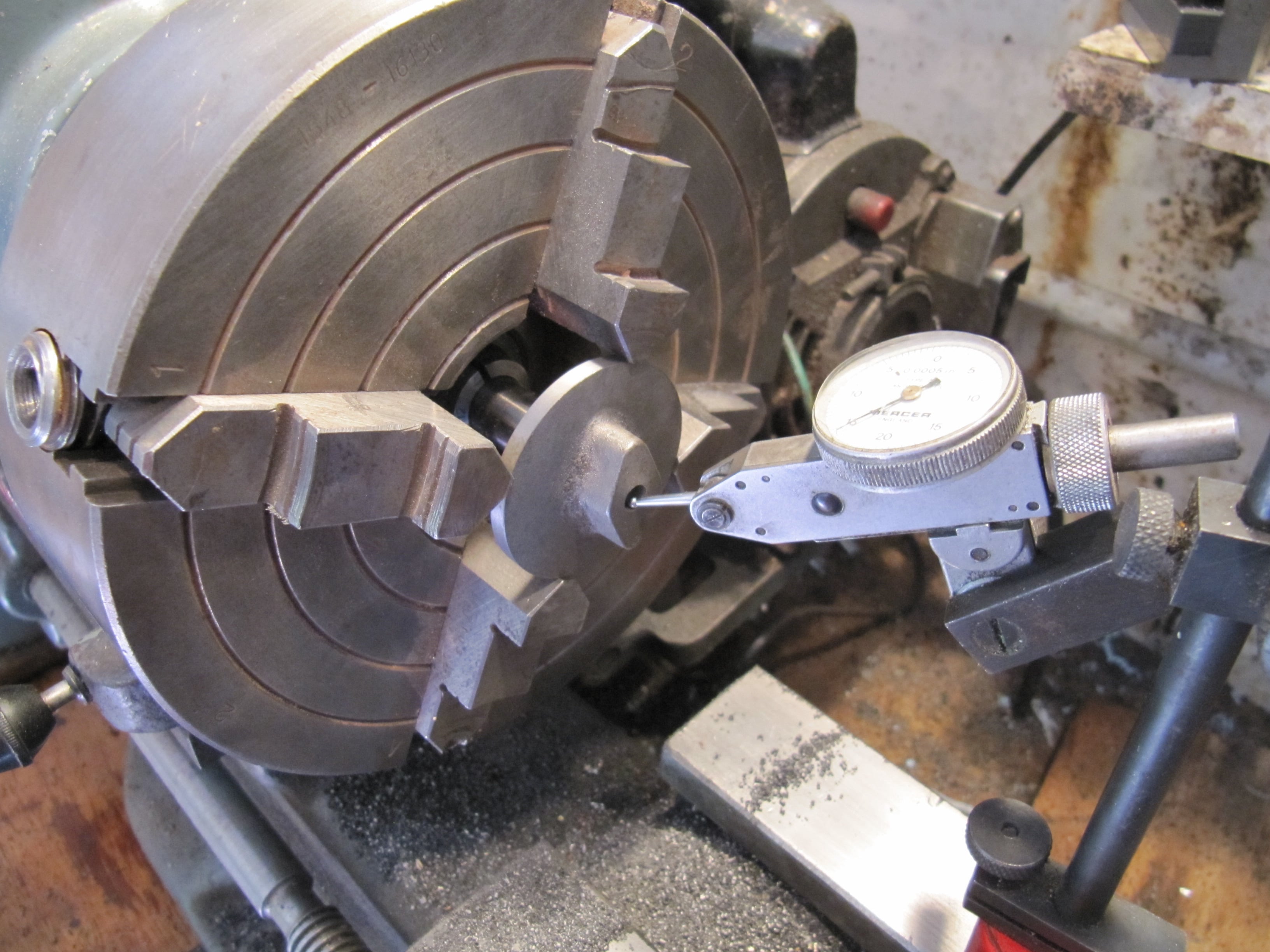

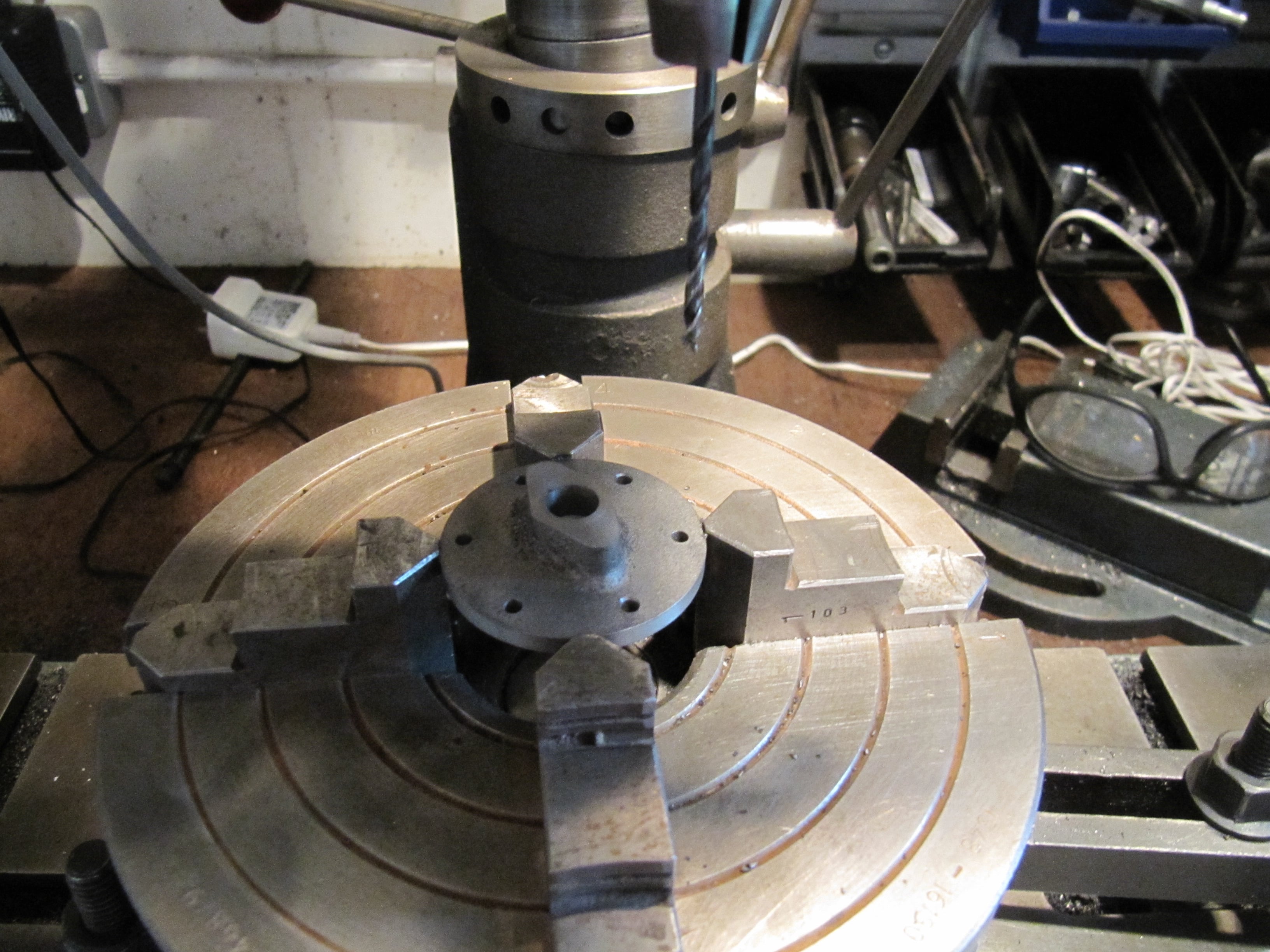

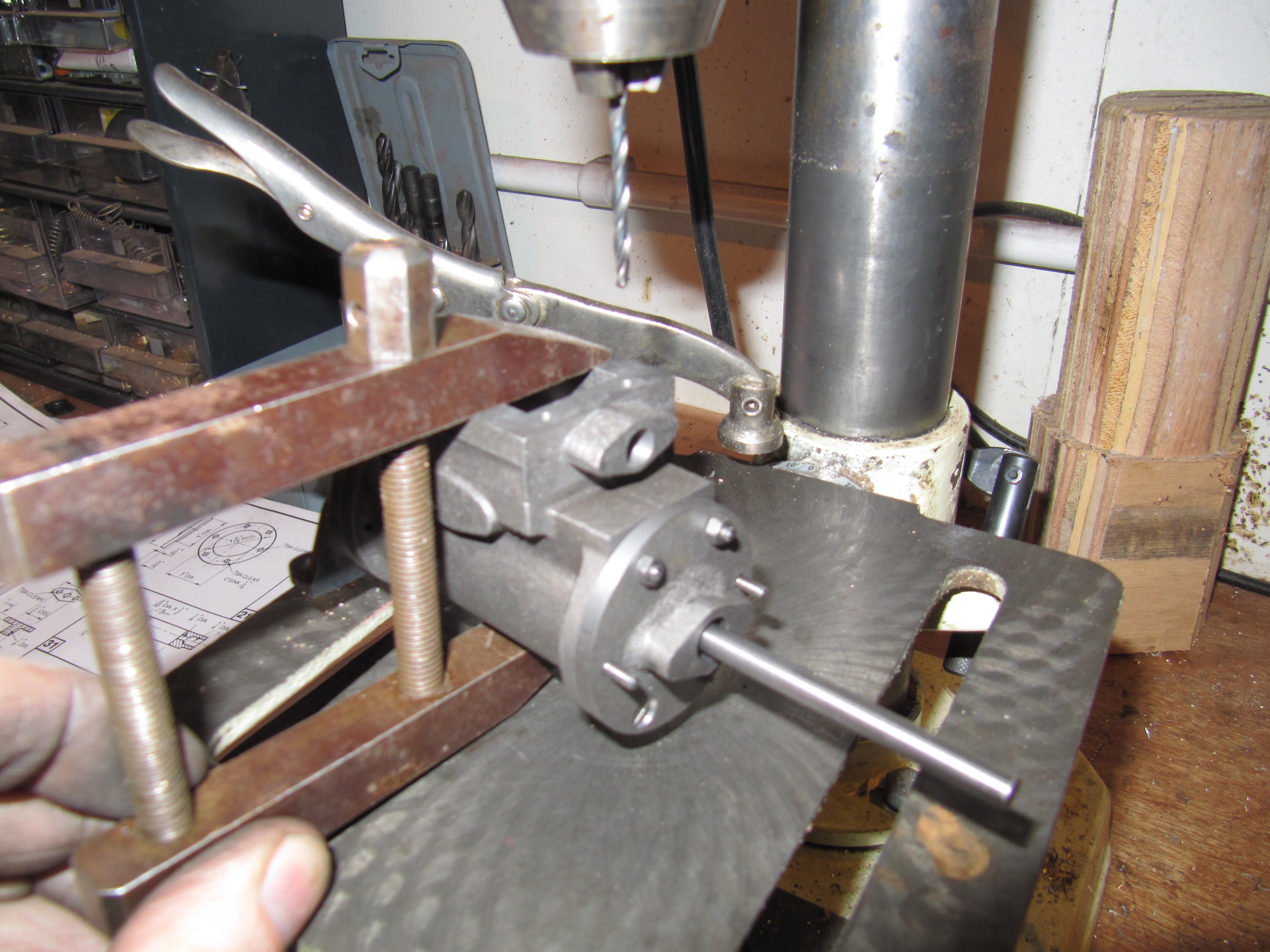

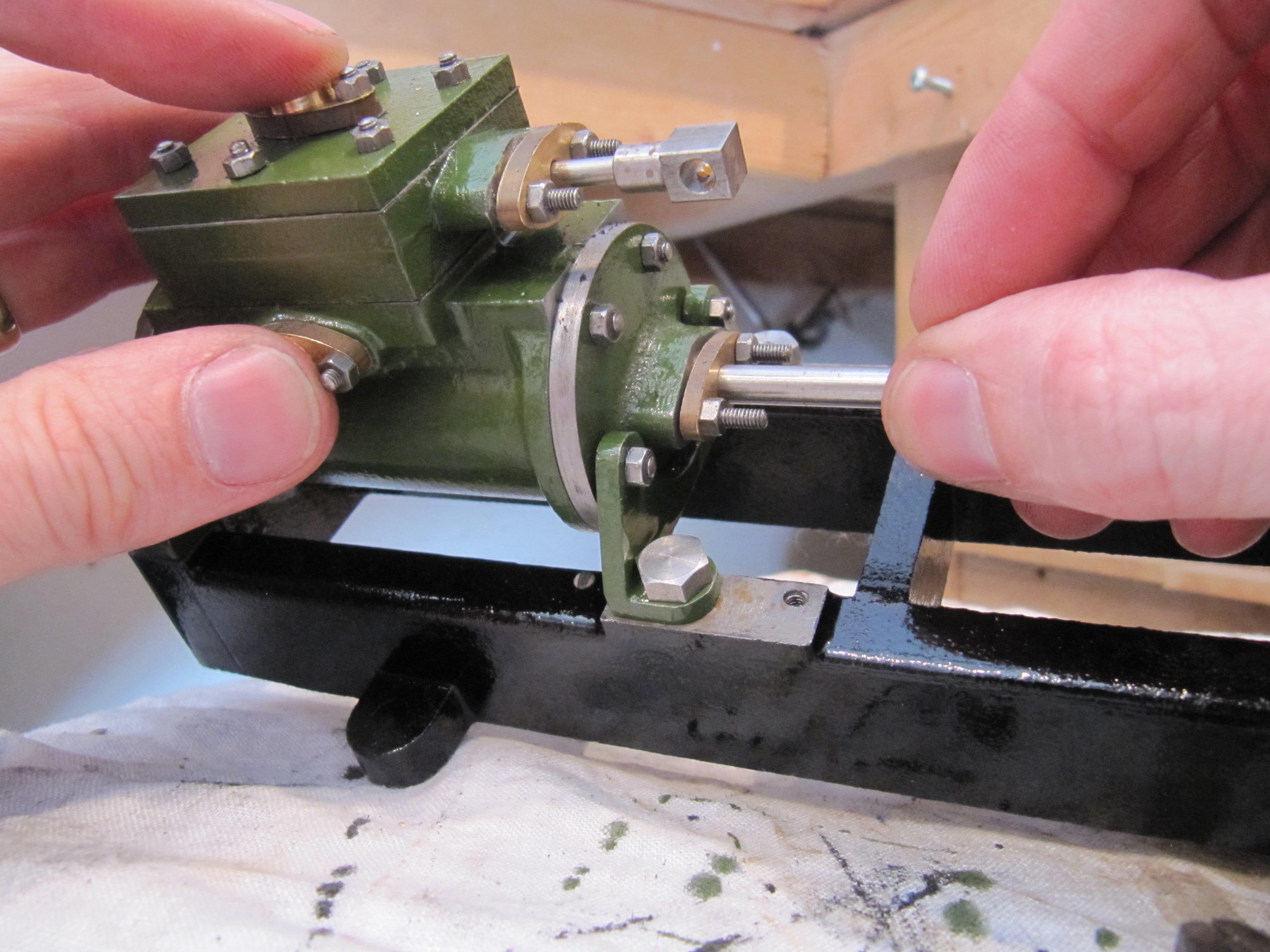

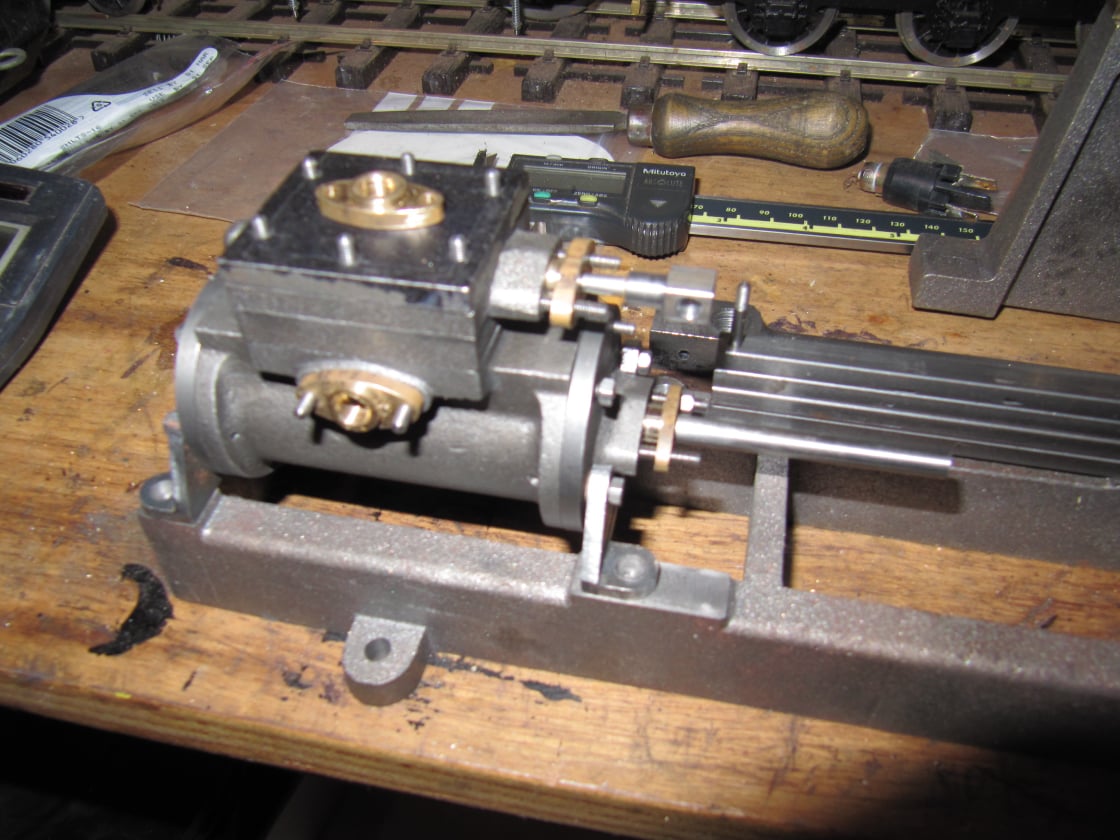

The Cylinder

The cylinder was machined before the piston so the latter could be made to suit.

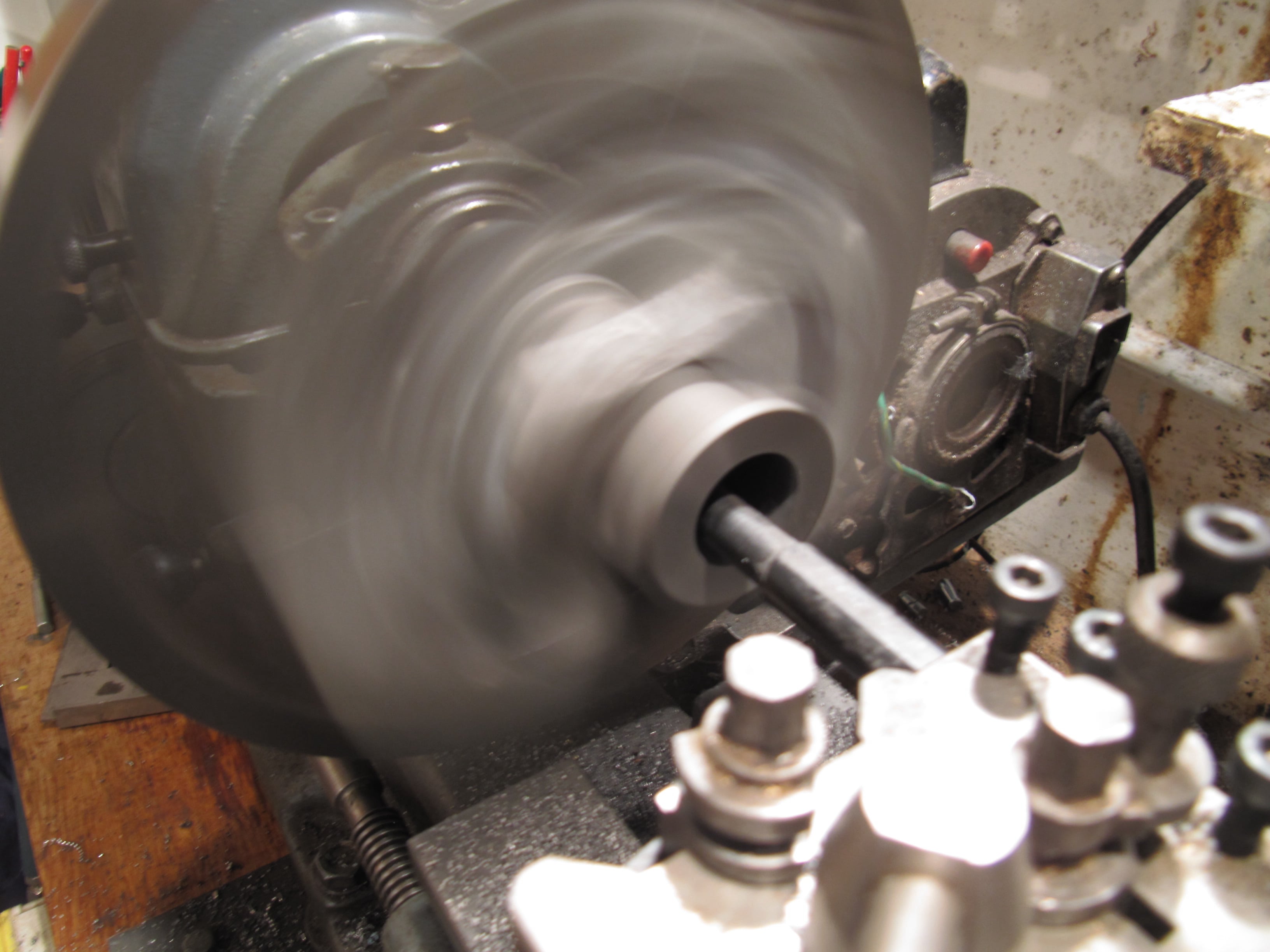

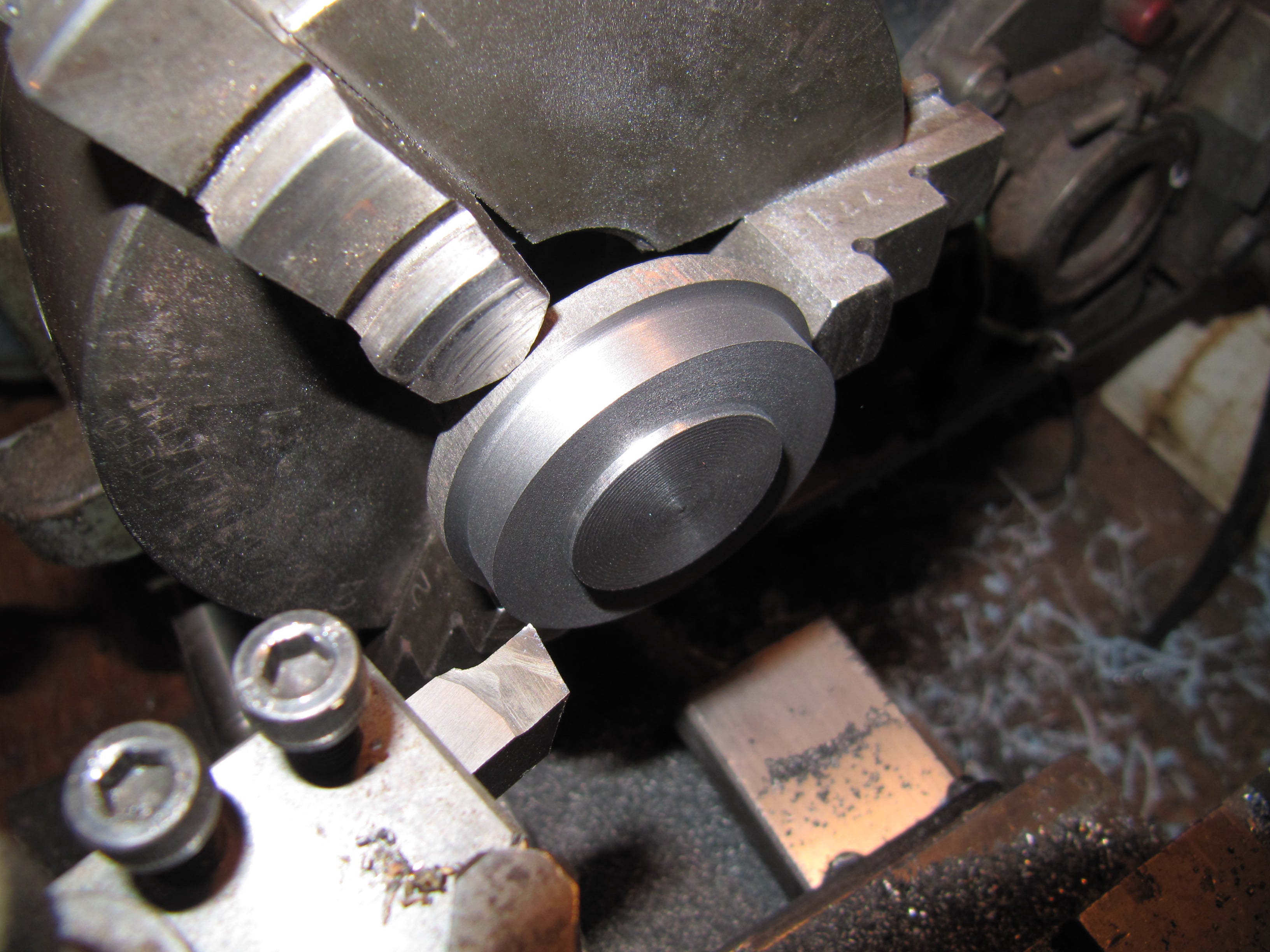

The cylinder bore needed to be parallel and round throughout and the diameter correct enough to suit the O-ring included in the kit.