Stuart Victoria

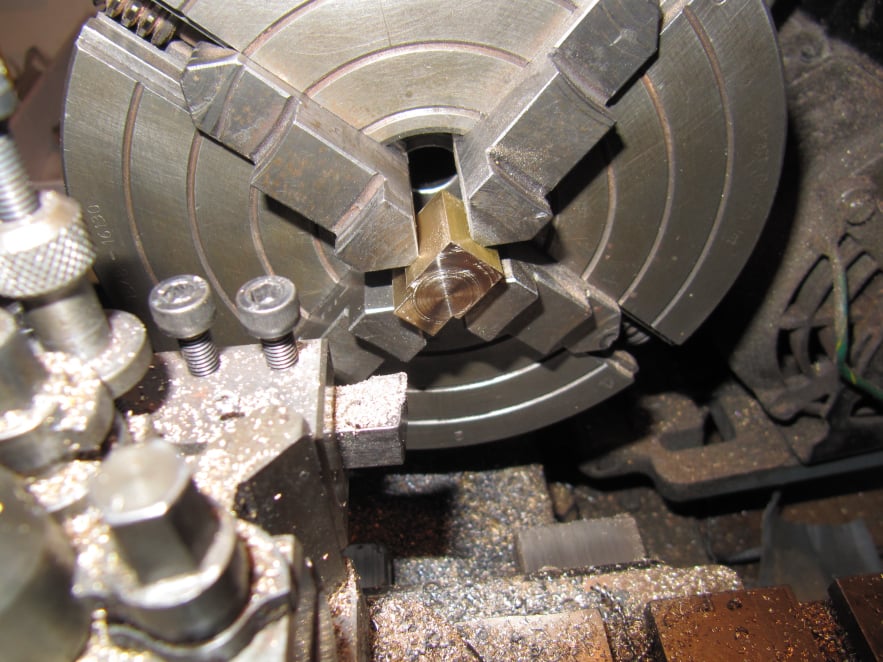

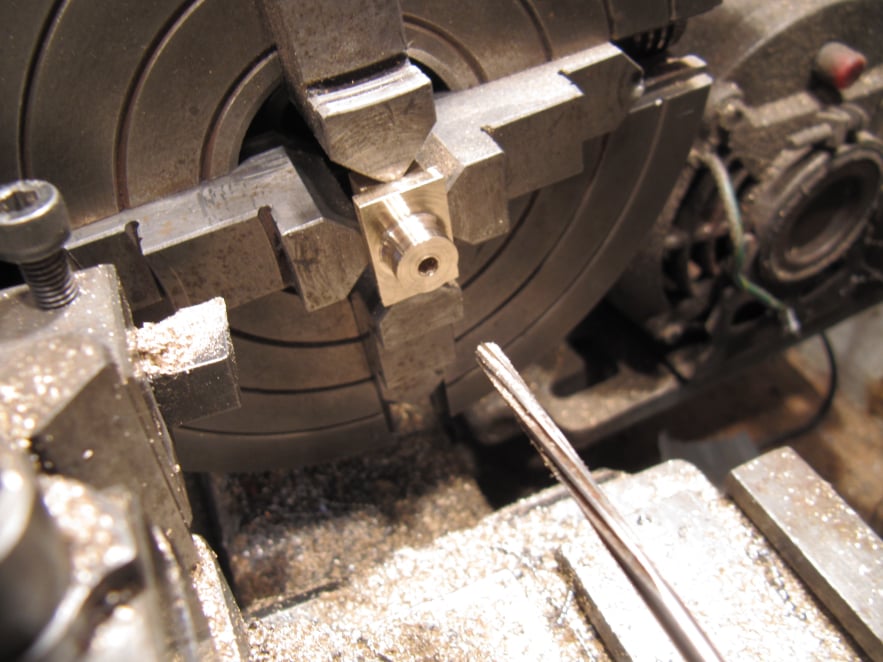

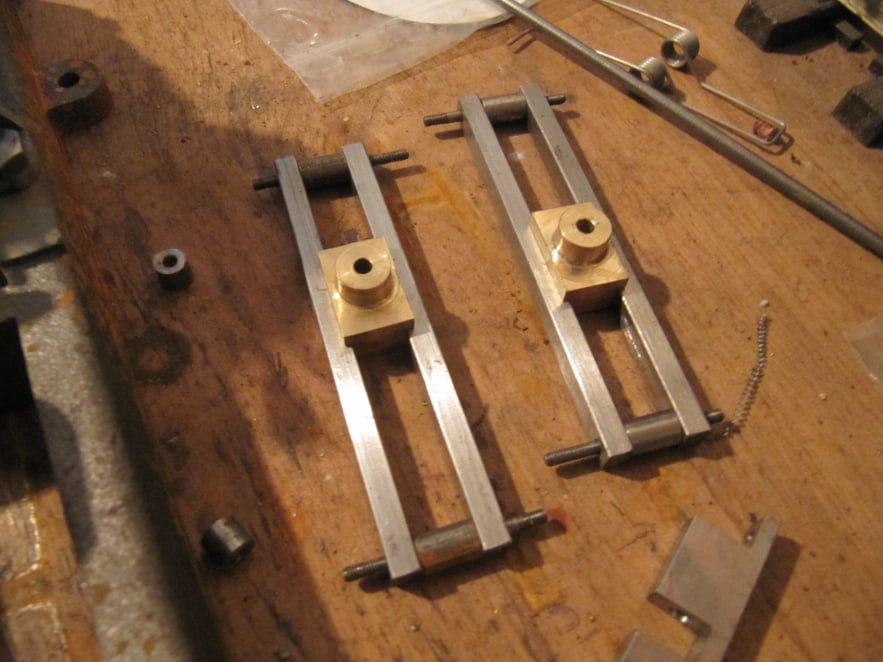

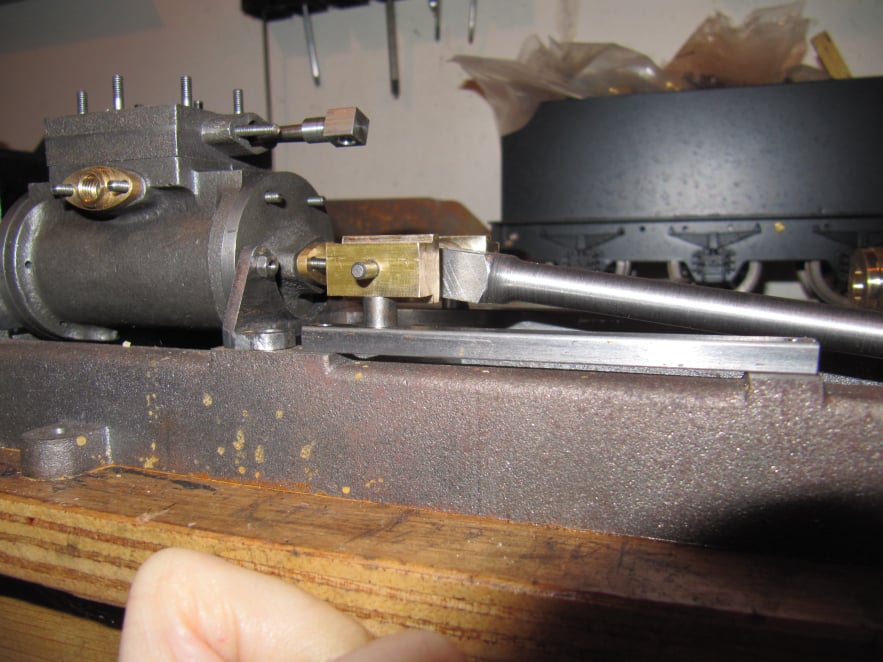

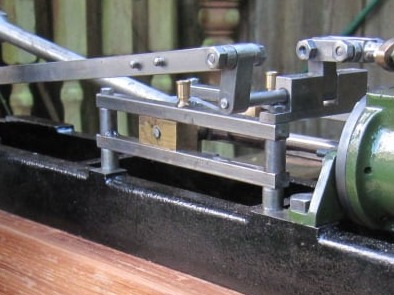

The Cross-Head and Guide Rails

The cross-head parts were machined before manufacturing the guide rails, so that any errors could be compensated for in the guide rail assembly.

The aim being to get a sliding fit with minimum friction.