Stuart Victoria

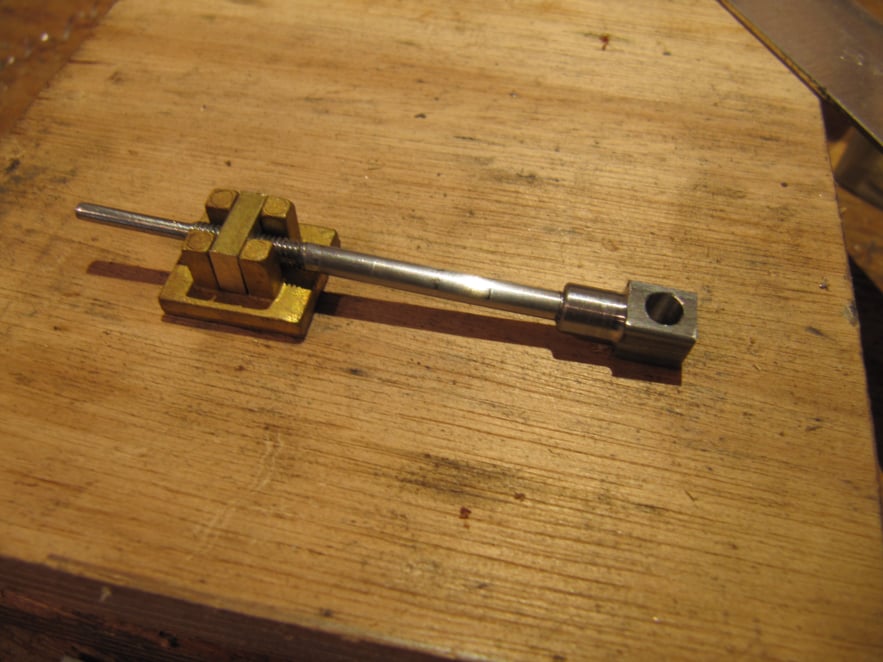

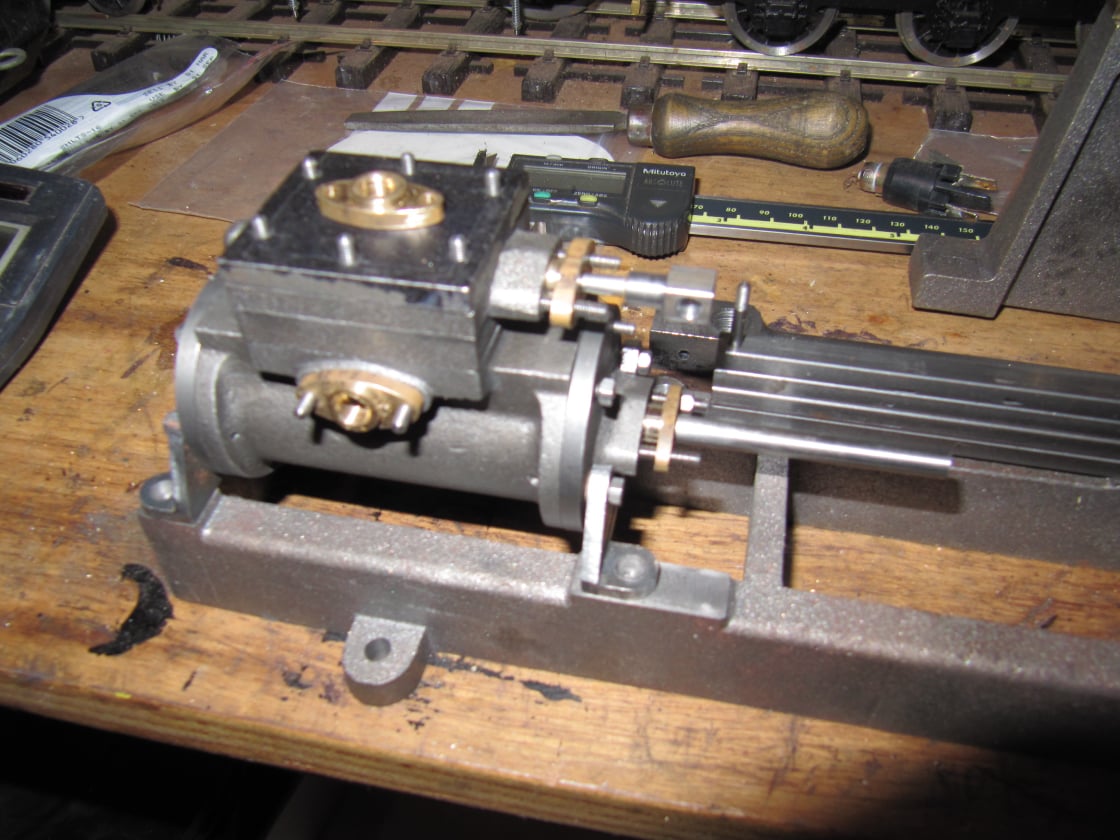

The Steam Chest, Cover and Valve

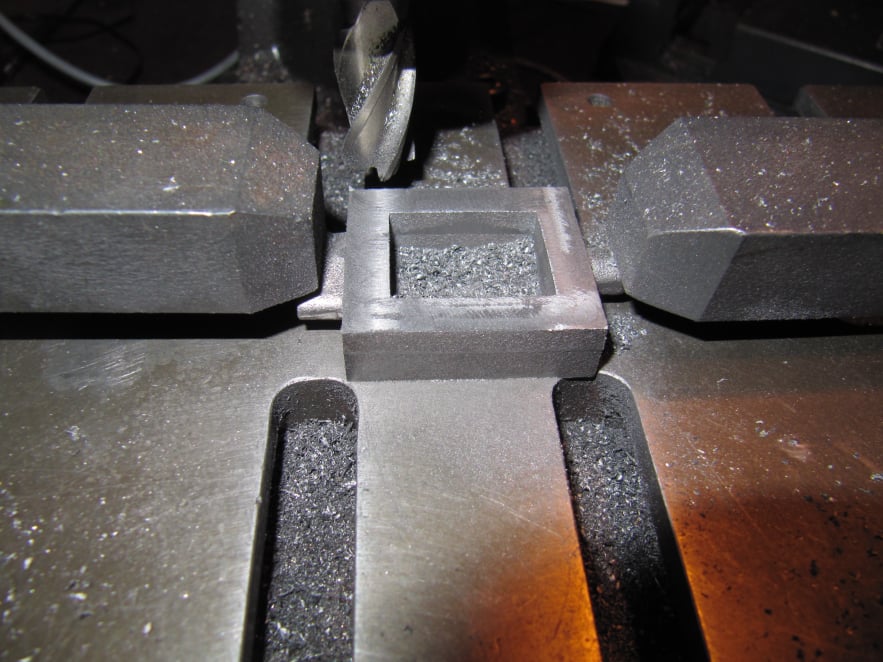

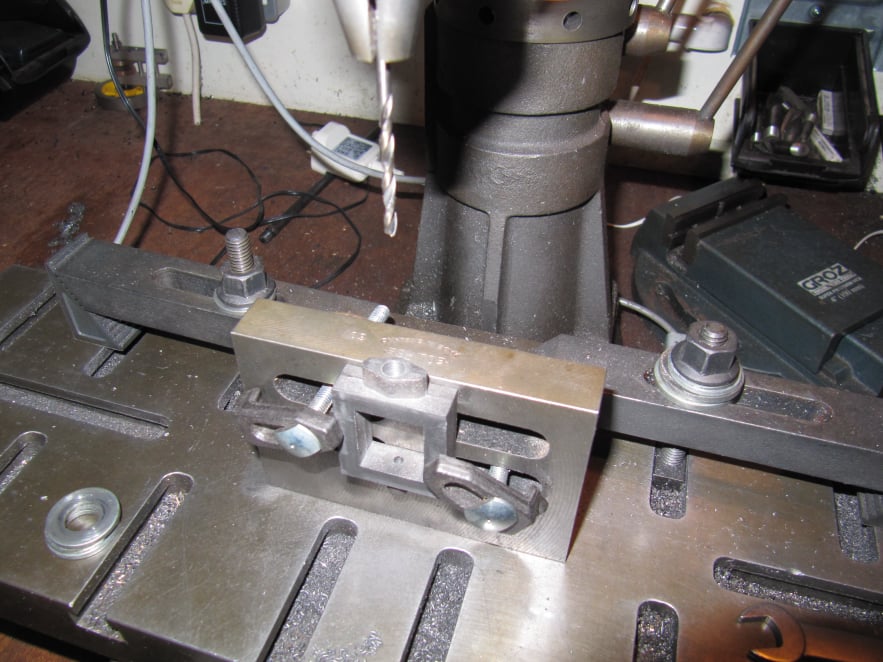

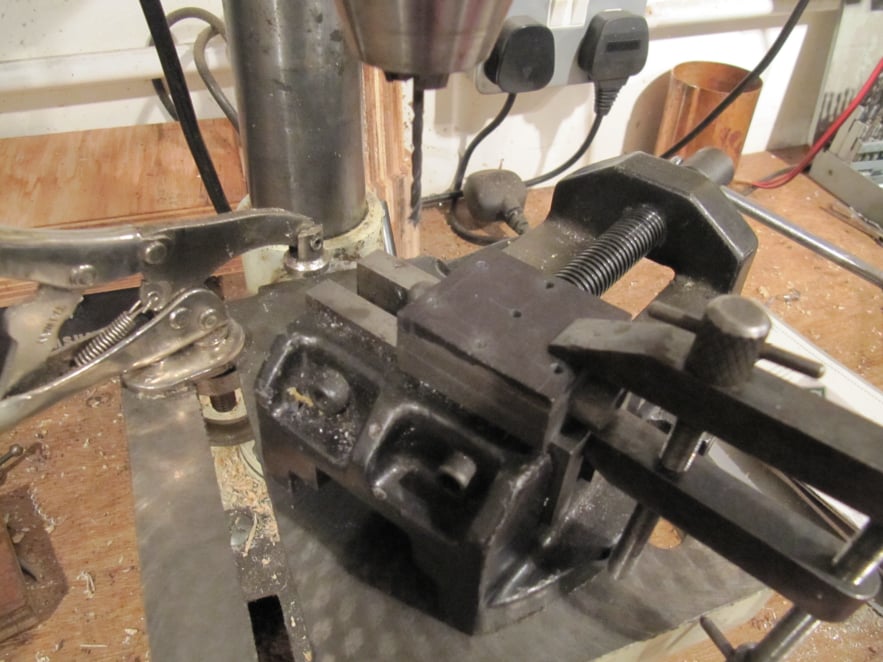

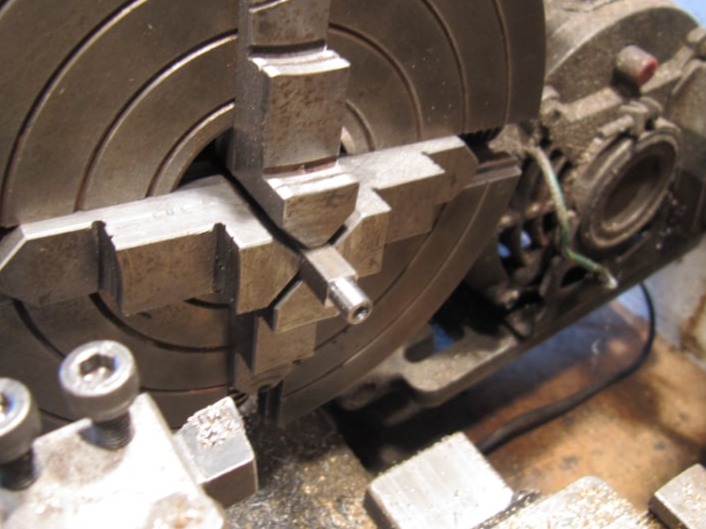

The steam chest and cover could be machined in the four jaw chuck or on the milling machine. The milling machine was chosen for the process described here.

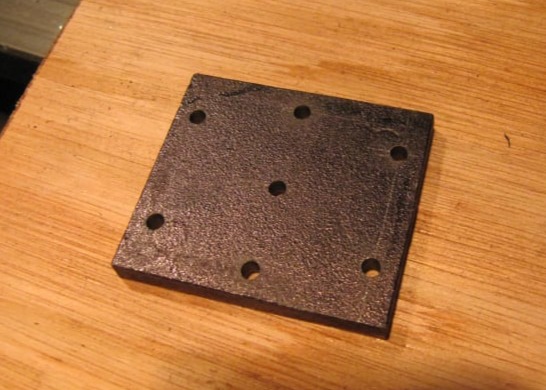

For this build the external faces of the steam chest were left rough cast.