Stuart Victoria

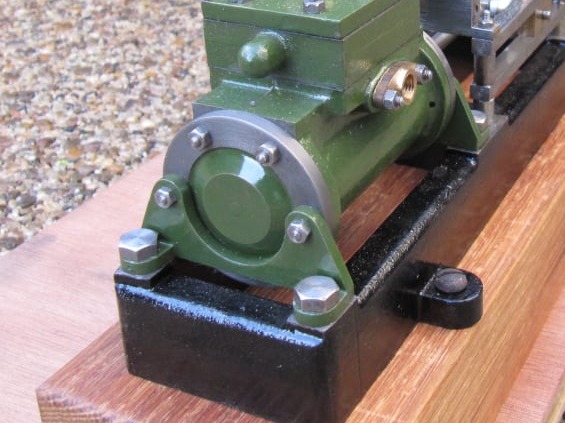

The Cylinder Brackets

The brackets were machined on the milling machine with some manual filing used to create the rounded corners.

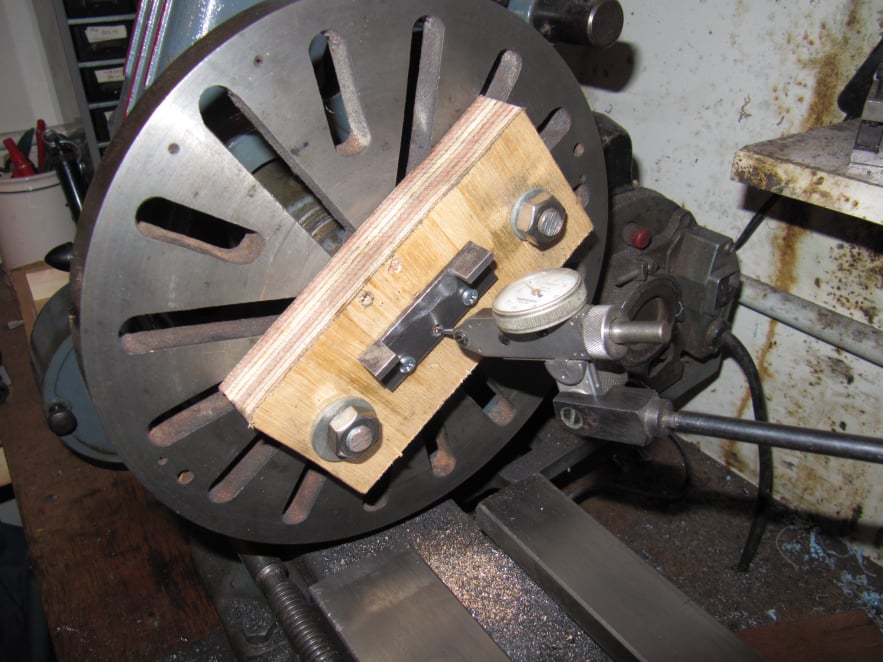

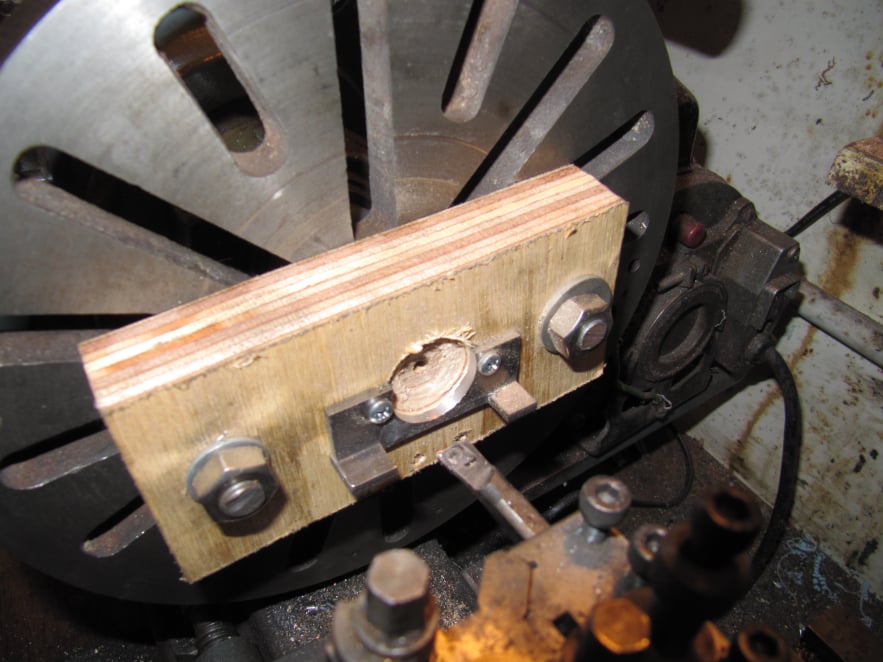

The inner radius was bored on the lathe.

No dimensions were considered critical although it was important to allow room for the mounting bolts to turn without fouling the vertical face of the bracket.