Stuart Victoria

The Box Bed

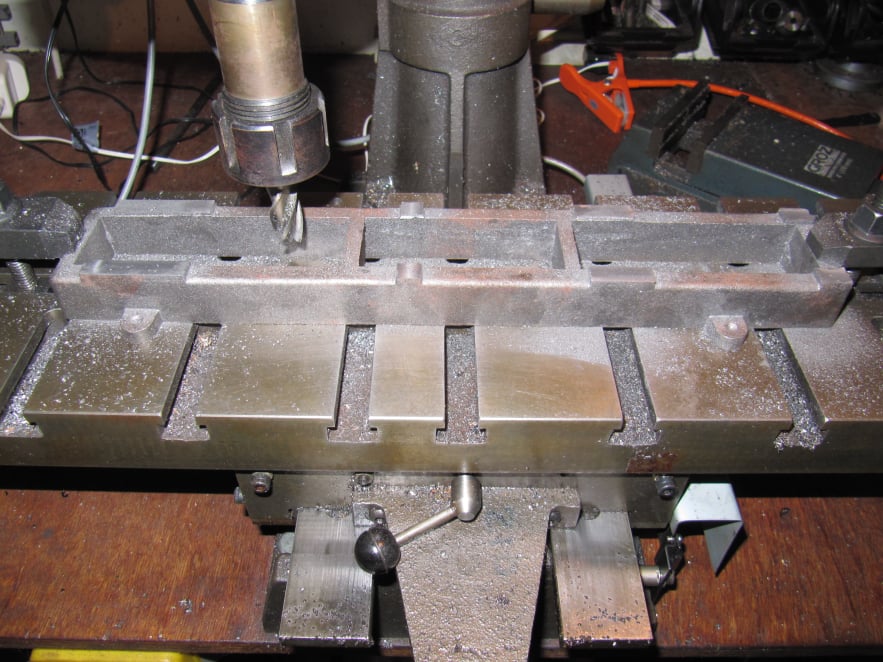

The box bed just required finishing of the top and bottom surfaces and the addition of the mounting holes.

The whole of the bottom was machined smooth so the engine could sit level but only the working surfaces were machined on the top face.

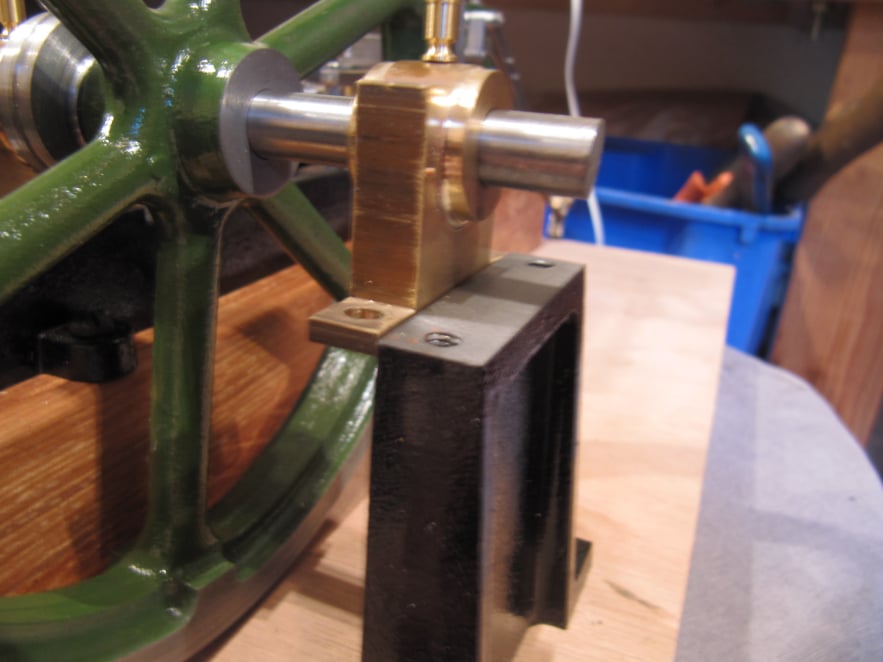

Overall thickness of the base was unimportant as long as the final size was taken into account when making the wooden base