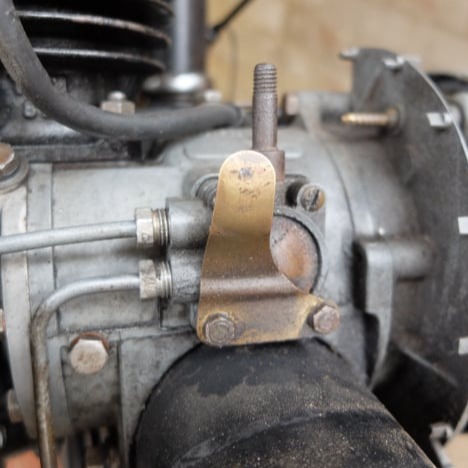

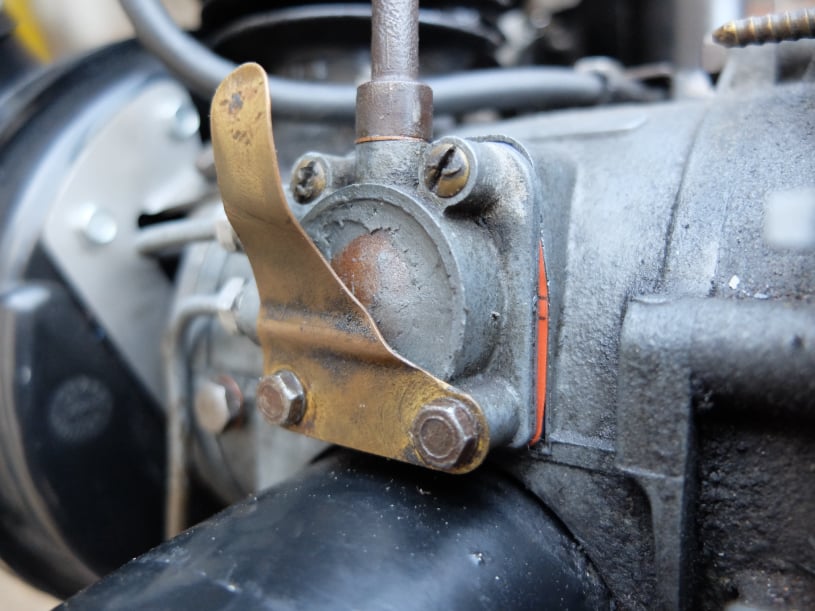

Velosolex Fuel Pump Rebuild

The Velosolex engine uses crank case pressure to drive a small diaphragm fuel pump to lift fuel from the tank to the Carburetor.

This page shows how to remove, check and rebuild the fuel pump.

Symptoms of a pump problem can be lack of fuel at the engine or bubbles seen in the fuel return pipe and an engine reluctant to idle.