Replacing & adjusting Points and Velosolex

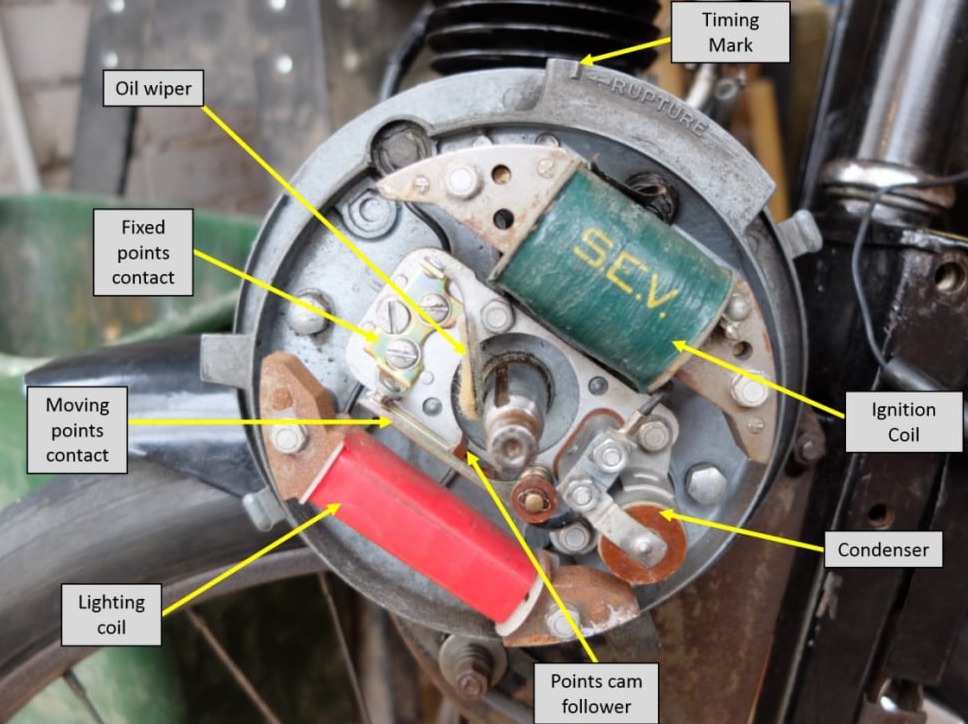

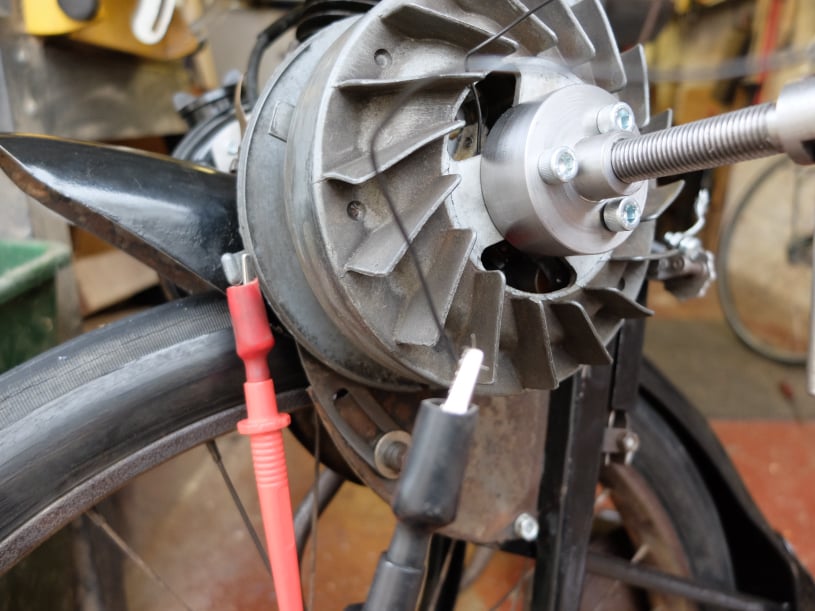

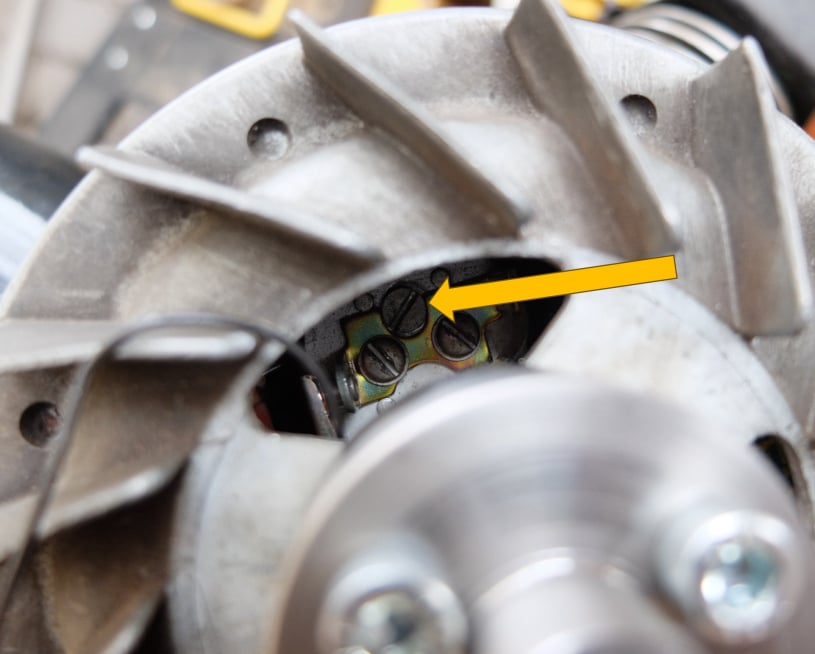

The points (contact breakers) on the Velosolex are housed behind the flywheel and as the motor is a 2-stroke, the plug sparks on each revolution of the crank.

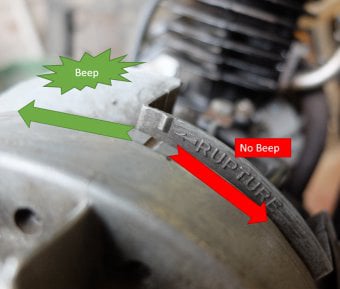

The spark has to be timed to get the engine to run correctly and a procedure is given here.