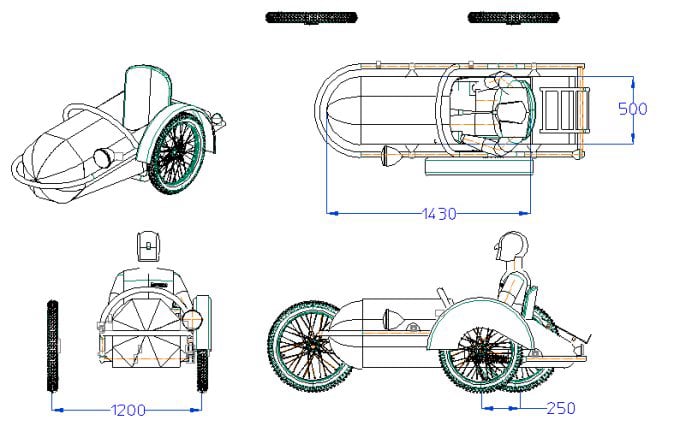

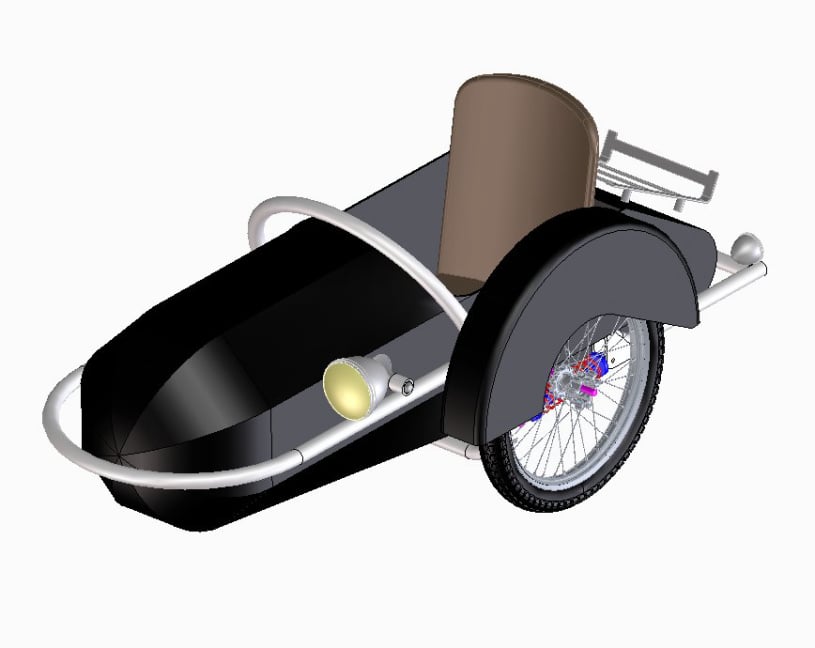

Sidecar Design

This page shows the design for the motorcycle sidecar and gives some guidelines for producing a sidecar suitable for a given motorcycle.

The chosen motorcycle was an R60/6 BMW. Not a hugely powerful machine and weighing 200kgs. So the design was decided to be a small lightweight sports chair, approximately 70kgs in weight in order to be appropriate for the bike. As a guide sidecar weight should be 1/3rd the motorcycle weight.

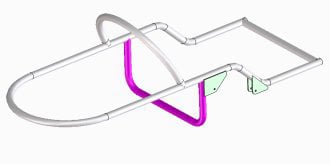

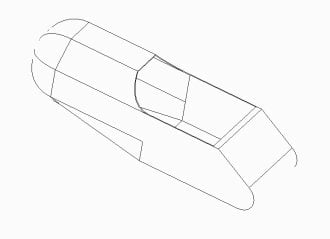

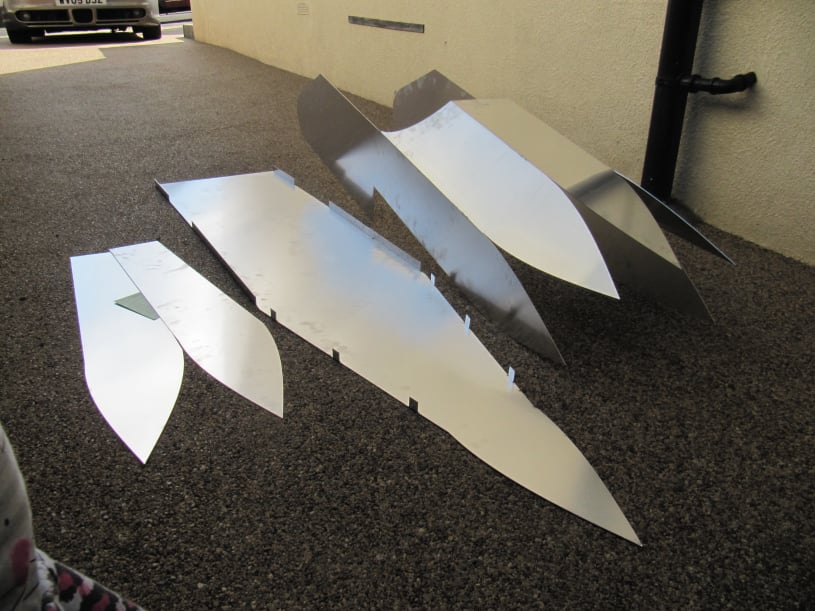

The developed design was based heavily on the classic Steib designs. These sidecars from Germany featured 8 segment "zeppelin" style bodies inside an external hoop frame. Originals were made from steel and were typically finished in black or drab olive paint.