Saab V4 Tappet Adjustment

This document describes a process which can be used to adjust the tappets on the V4 engine.

This process should be carried out with the engine cold.

This document describes a process which can be used to adjust the tappets on the V4 engine.

This process should be carried out with the engine cold.

Easier access is afforded to the engine with the bonnet removed. This just requires the removal of the two R-clips at the bonnet hinges, and unplugging of the screen washer tube.

To make turning the engine by hand easier, the spark plugs should be removed from all four cylinders

The airbox and rocker covers need to be removed.

The rocker covers have five 10mm screws each, which are best accessed using a socket on an extension bar (arrowed).

The LHS rocker cover also has a breather tube to be undone.

With all the bolts removed both covers can removed and, with care, the gaskets are often reusable.

Without compression, the engine can be turned by pulling on the fan belt or by using a 17mm socket on the balance shaft pulley.

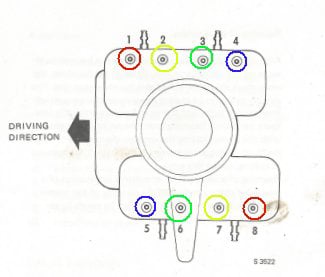

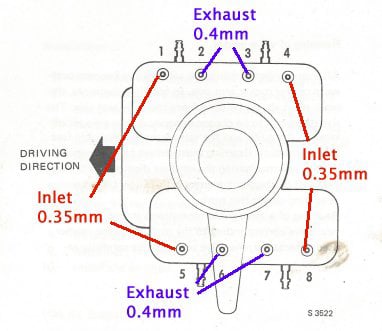

As the engine is turned and the rockers press the valves, a rule of diagonal opposites can be applied. So when valve 1 is activated, valve 8 can be adjusted. When valve 2 is down the valve 7 can be adjusted, and so on.

The inner rockers operate the exhaust valves. The outer ones are the inlet.

Exhaust Valves should have a clearance of 0.4mm and the inlet 0.35mm.

Adjustment can be made by turning the adjustment bolt on the top of the rocker. There are no lock nuts, the bolts just use and interference thread.

The bolt should be turned until the feeler gauges are a friction/sliding fit in the gap.

The original cork gaskets on the rocker covers can be replaced with high quality silicone copies from Real Gaskets. Silicone gaskets are not only reusable, but aren't so susceptible to leaking. As an endorsement, this car has had silicone gaskets fitted for 20 years with good results.

When replacing the covers the bolts should be tightened "across" the cover and only just tight enough. Over tightening can deform the covers and cause oil leaks.

HTML Code Creator