Points Replacement System

The distributor bearings had some wear on the Saab and so a contacts ignition kit was installed which was less sensitive to this problem.

The distributor bearings had some wear on the Saab and so a contacts ignition kit was installed which was less sensitive to this problem.

As instructed - the coil resistance was checked to ensure it was over 1.5 ohms. This was measured with the coil disconnected using a multimeter. It measured 3 ohms - so was acceptable.

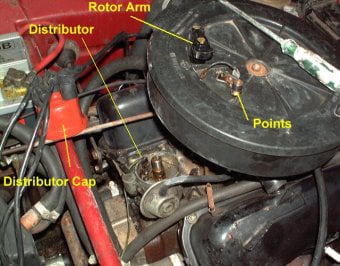

Next the distributor cap was removed and the rotor arm pulled off. The points were disconnected and also removed.

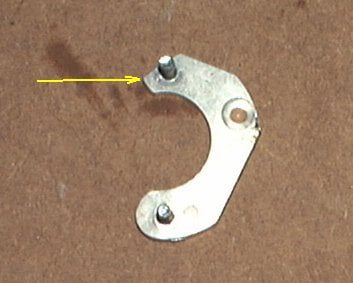

When the adapter plate was fitted, it was found necessary to file off the top corner of the plate shown below, to stop it fouling on part of the distributor. Only the smallest amount of filing was required.

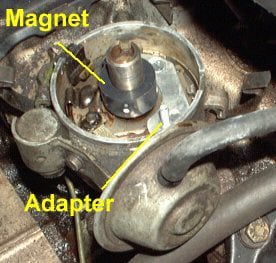

Once the adapter was installed then the magnetic ring was fitted. This was just a push fit on the distributor shaft. As recommended by the instructions the position of each magnet was marked with Tipex.

The sensor plate was now screwed onto the adapter plate using the 2 nuts provided.

The clear plastic strip shown in the photograph was the feeler gauge used to set the magnet and sensors the right distance apart.

The distributor was now rebuilt using the old rotor arm and cap.

The engine was turned to top dead centre on cylinder number one and the distributor turned so that the middle of the sensor was aligned with one of the white dots.

To make the electrical connections the red lead was connected to the positive on the coil and the black to the negative on the coil.

The engine started first time but it was found that the timing had retarded by about 16º. This was reset using a strobe. It was noticable that the timing mark was rock steady and didn't wander about like it did with the points.

Finally the wiring was tidied up and made weathertight.

HTML Website Creator