Puch VF/VZ50 setting the timing

Two-stroke timing has to be set right not only for the best performance, but also so the bike will run in the right direction!

The bike manual should specify what the timing should be, it might be specified as a piston distance below top dead centre (TDC) or the number of degrees of crank rotation before TDC.

On the Puch VF/VZ50. The manual states that the spark should occur

0.8mm -> 1.2mm before TDC and the contact gap should be 0.4mm.

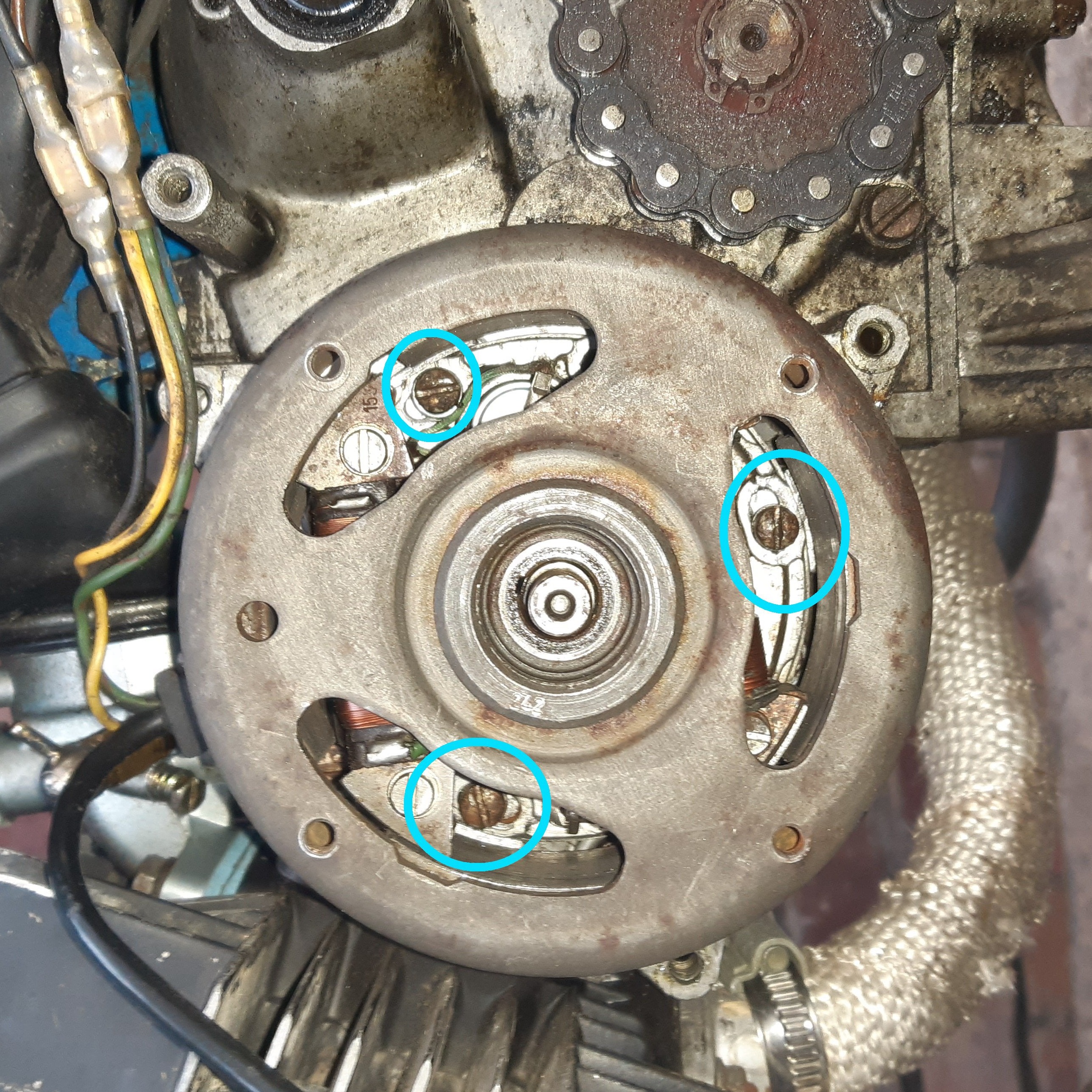

The process is simple enough and only slightly difficult because some of the work has to be done through the flywheel.