MZ TS125 Engine and Gearbox Rebuild

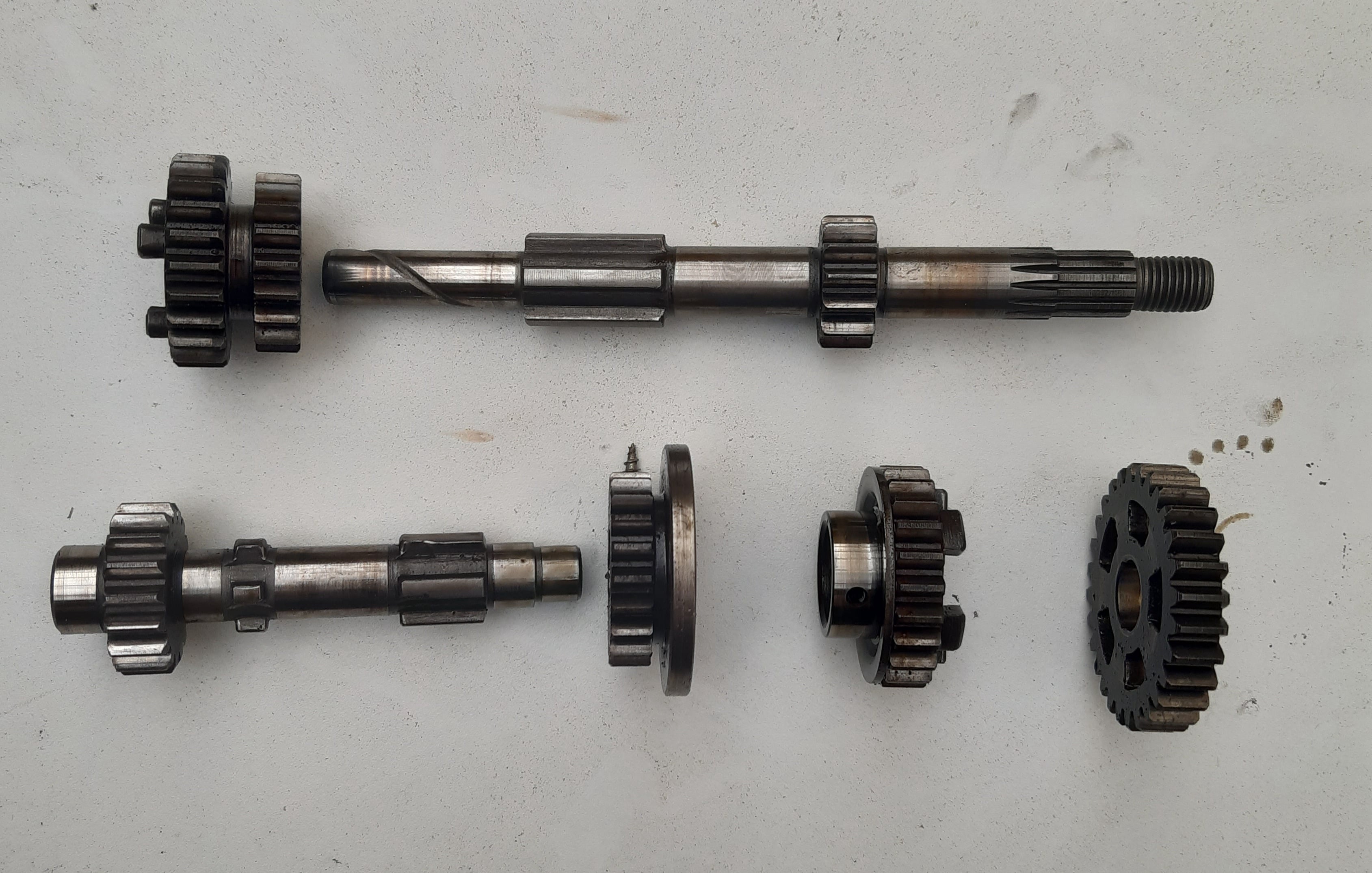

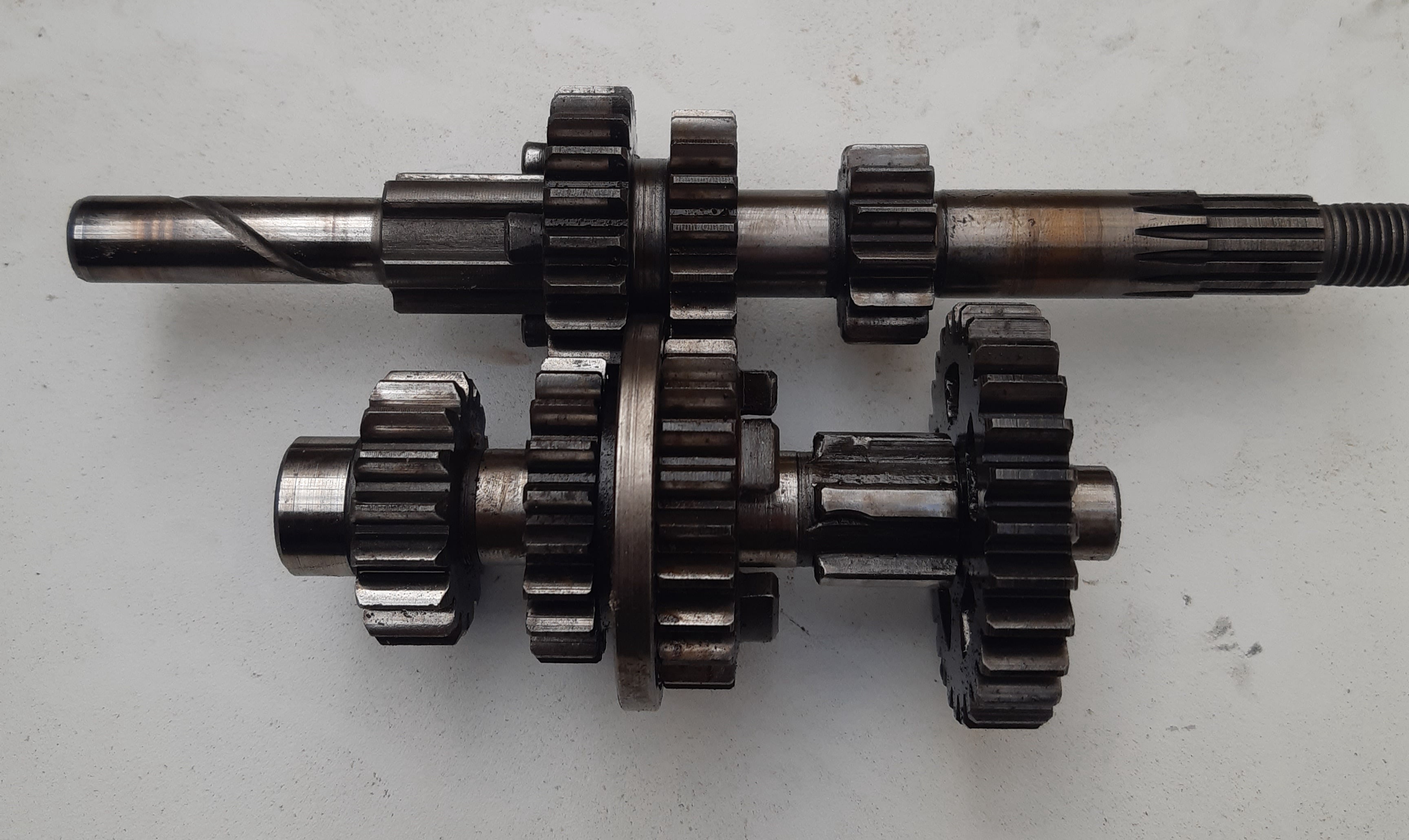

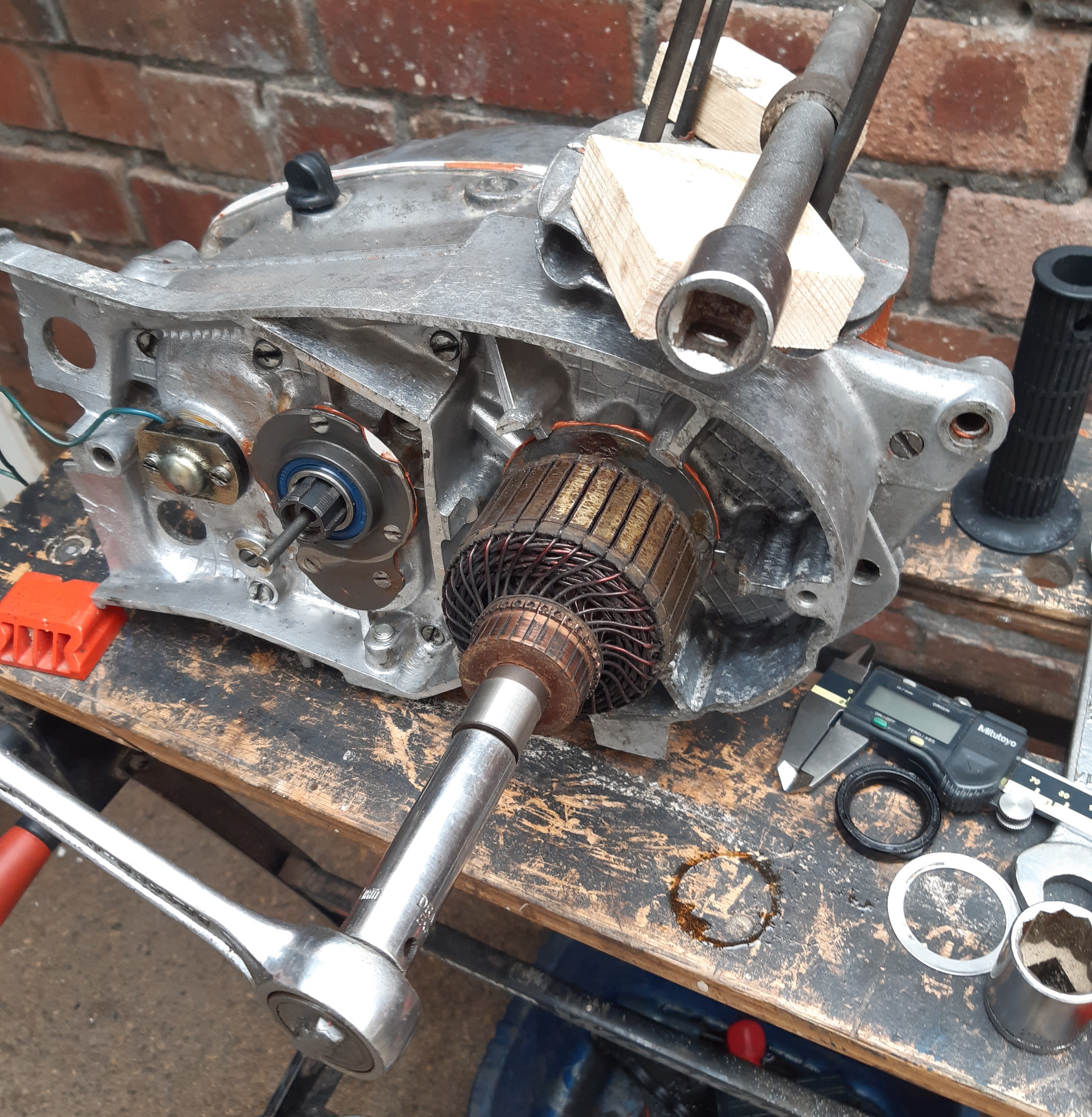

The engine was seized and there was evidence of water in the right hand side which had damaged the dynamo and rotor. However the gearbox oil had done a good job of preserving the gears, crank and clutch.

The engine was seized and there was evidence of water in the right hand side which had damaged the dynamo and rotor. However the gearbox oil had done a good job of preserving the gears, crank and clutch.

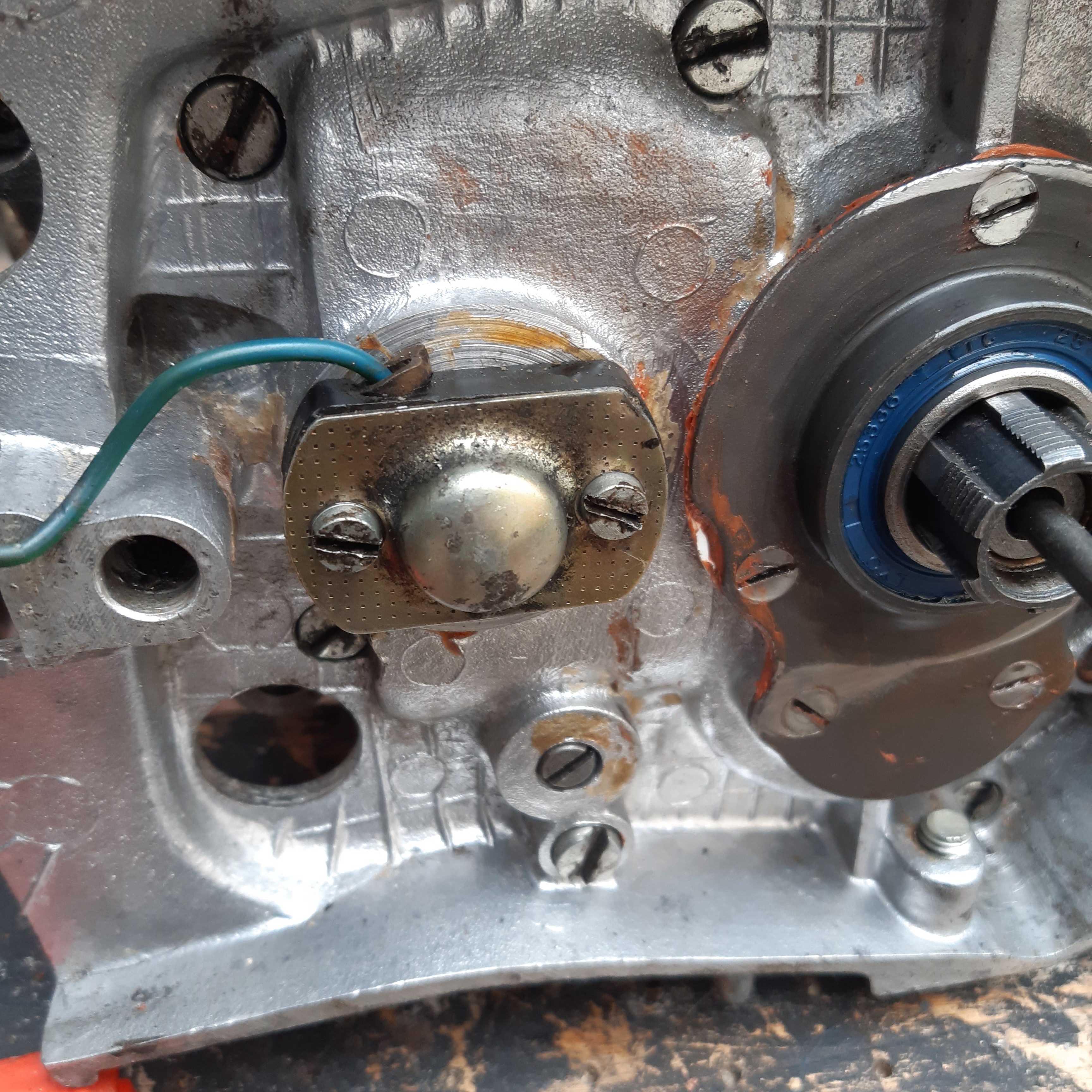

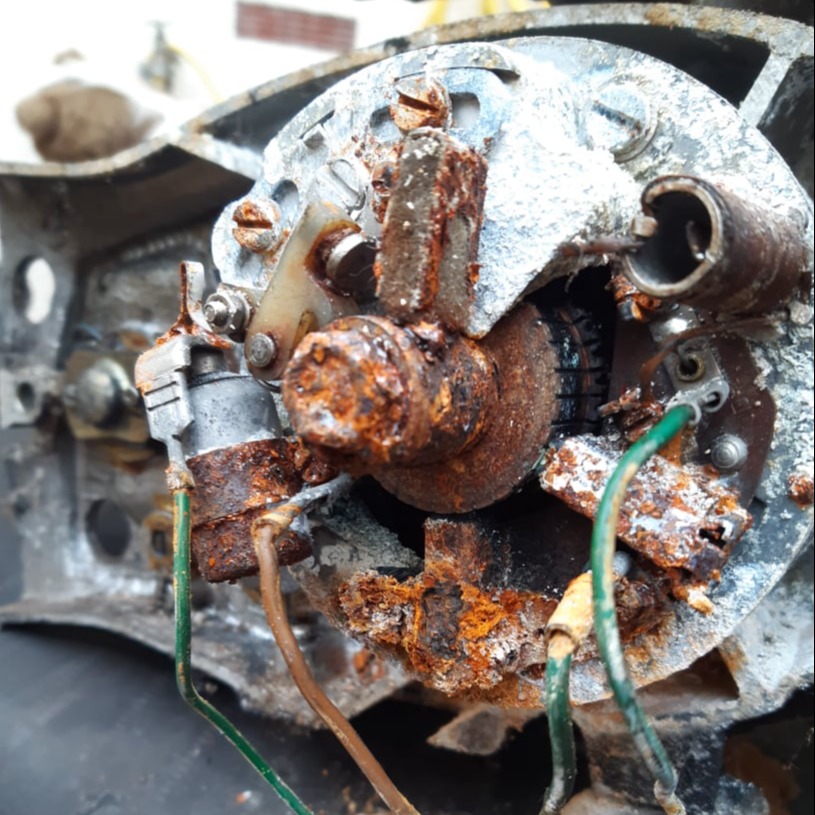

The dynamo condition is shown here. All of the electrical parts were crumbling from years of corrosion.

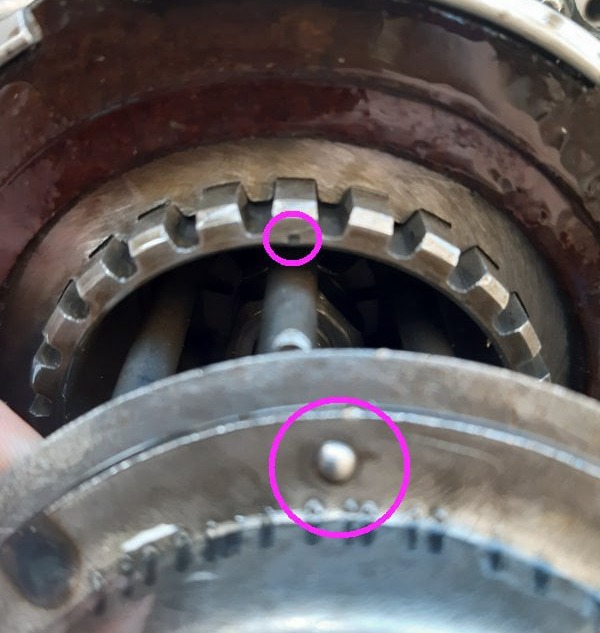

Fortunately the points cam was a bolt-on part and replaceable, and the rest of the crankshaft cleaned up OK.

Martin at Burwins Motorcycles, a long time spares supplier of MZ parts, helped source a good secondhand rotor and stator.

The seized piston had to be removed from the bore using a wooden drift and a hammer.

The cylinder was given to a local motor engineers for re-boring whilst an oversized piston and rings was sourced.

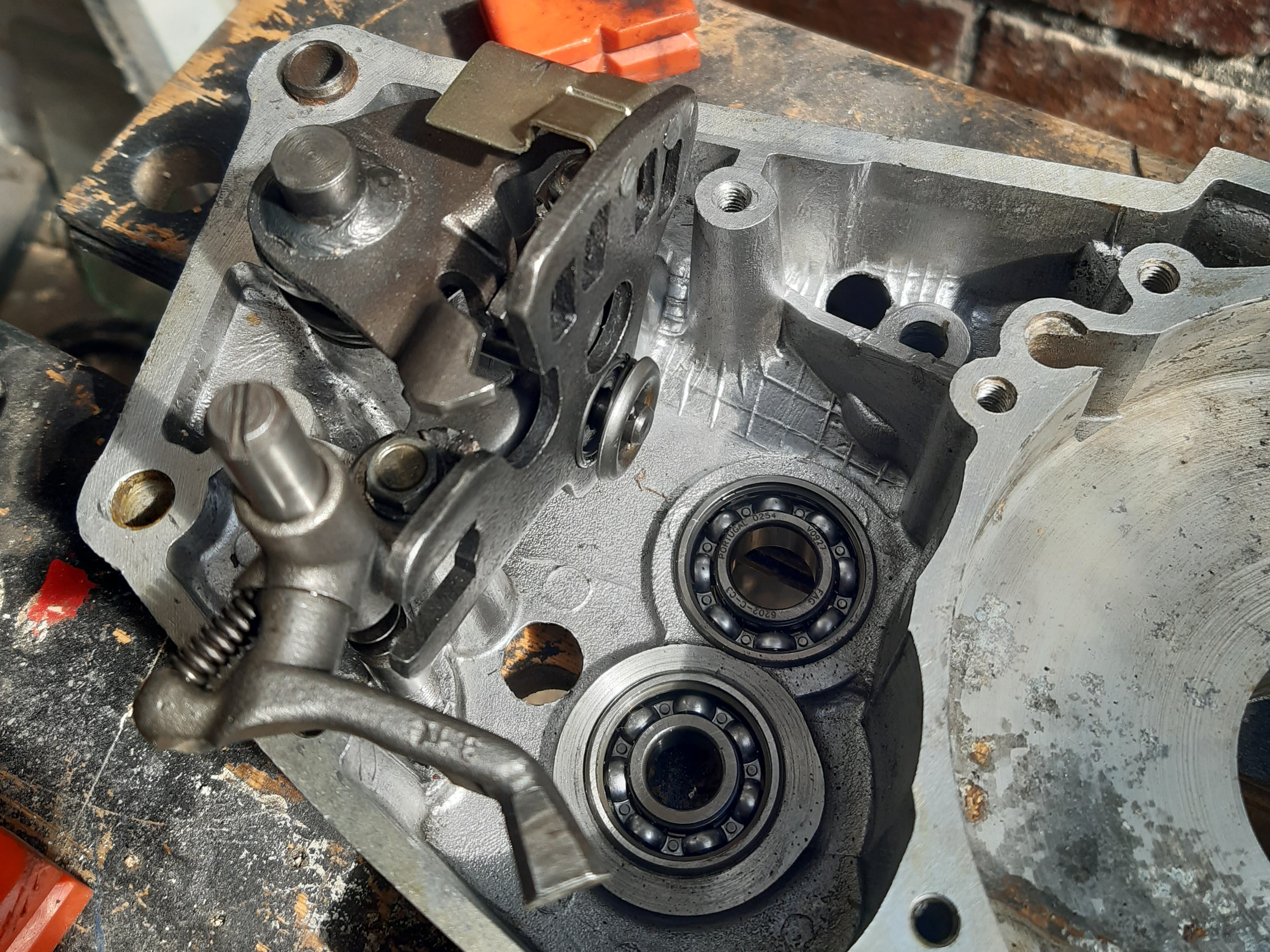

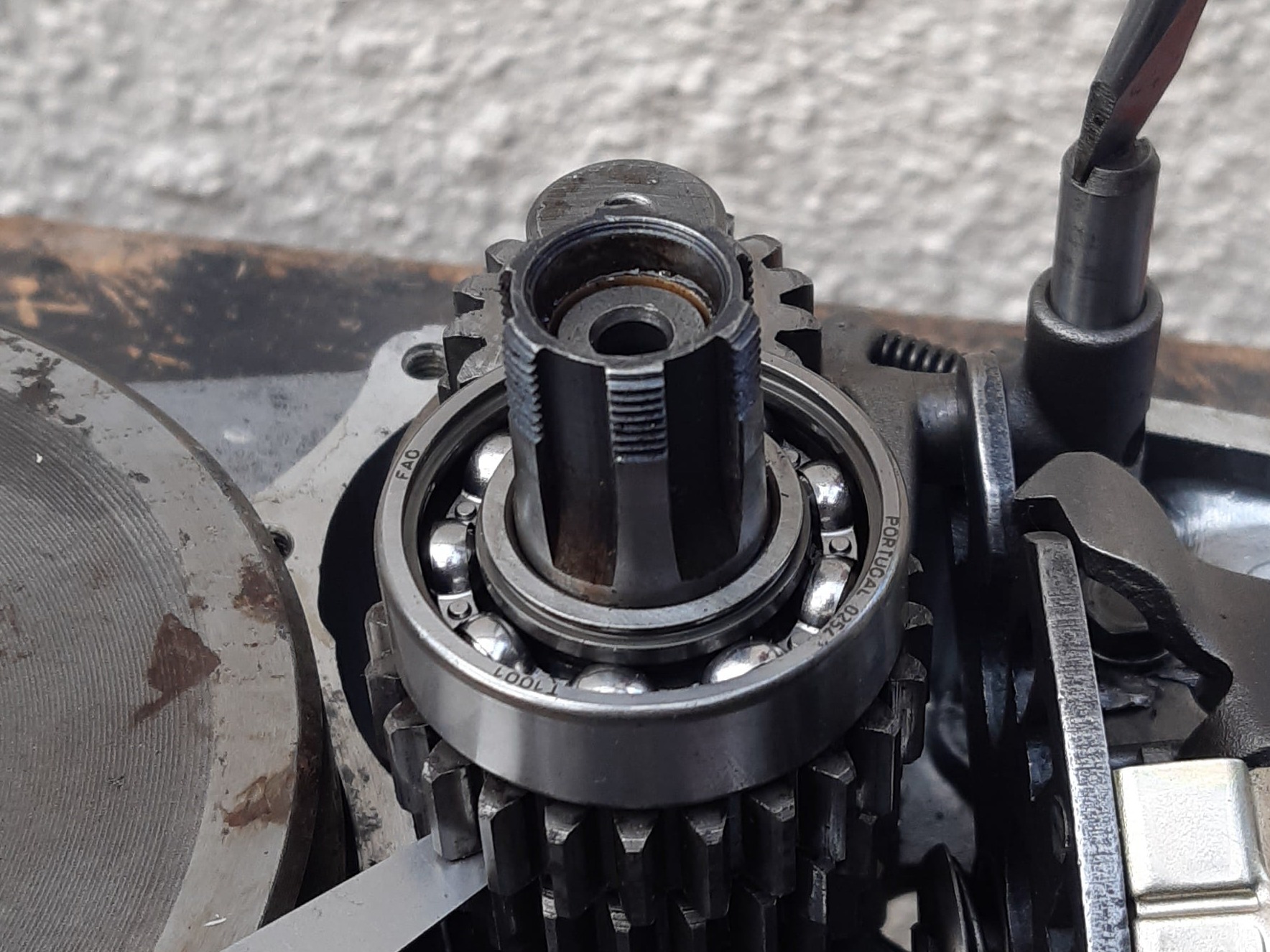

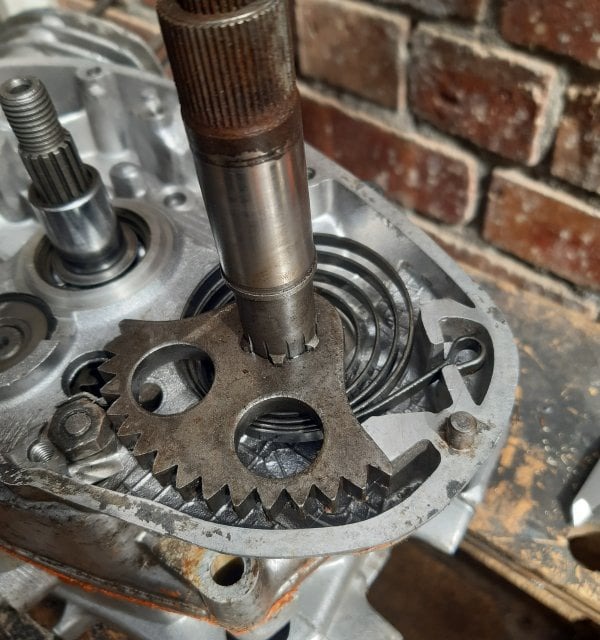

The rest of the engine and gearbox was stripped out and new bearings were ordered for all the gearbox shafts and the crankshaft along with any seals.