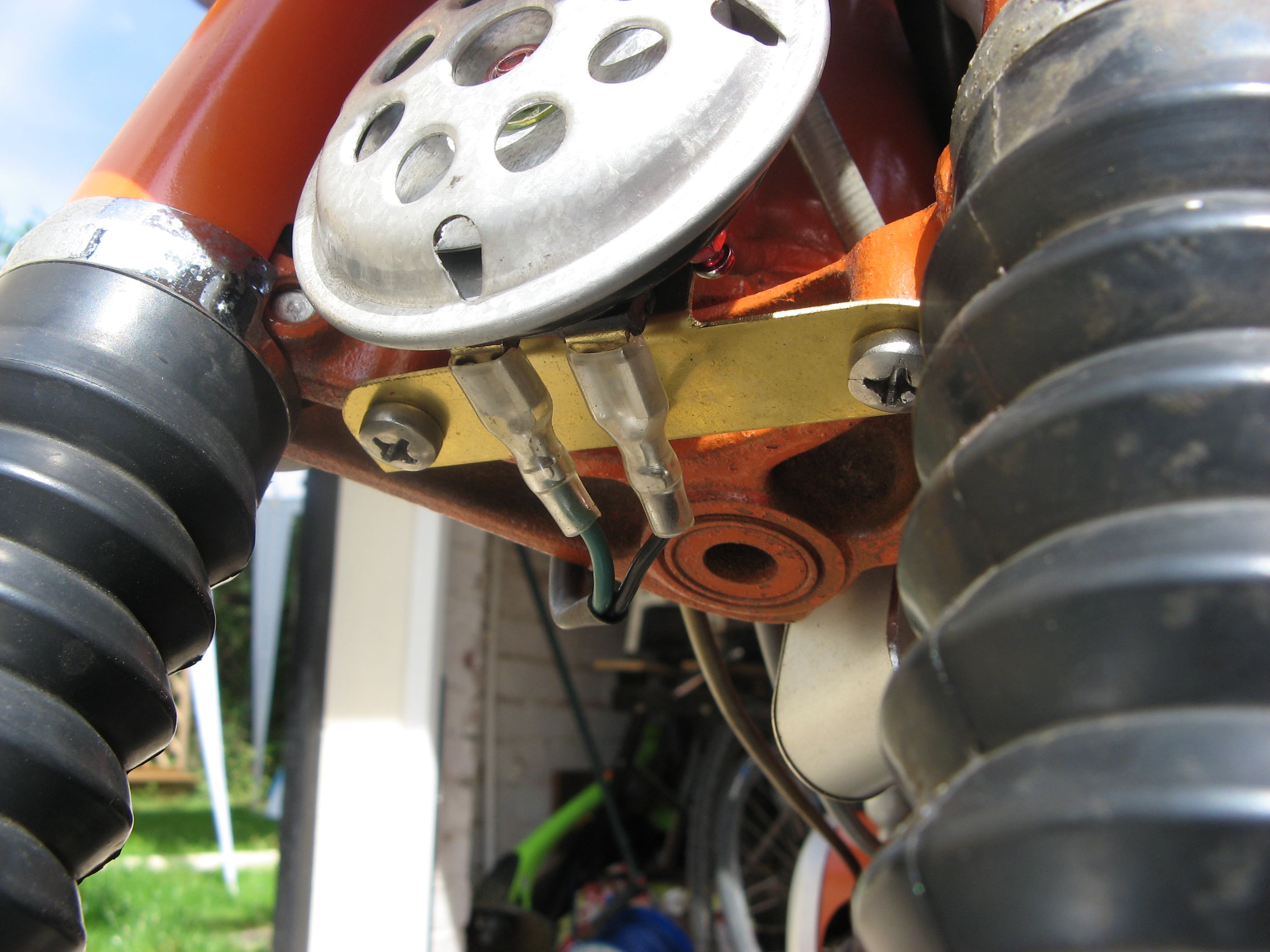

Restoring the Honda S90

This page gives some information on the bike restoration.

The aim was to put the bike back into a usable condition, rather than restore every fine detail. It needed to be tidied up cosmetically and made safe. It would also need to pass the road-worthiness test at the garage.