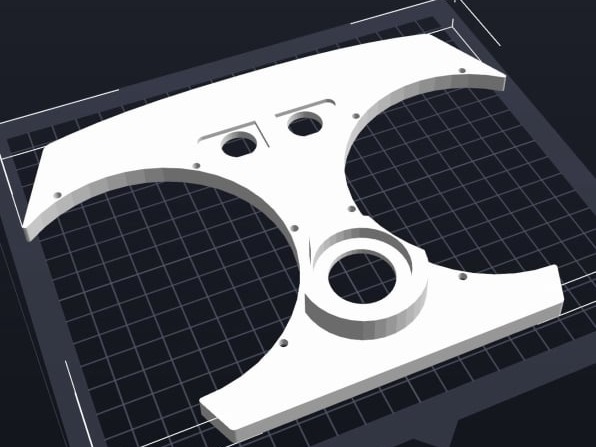

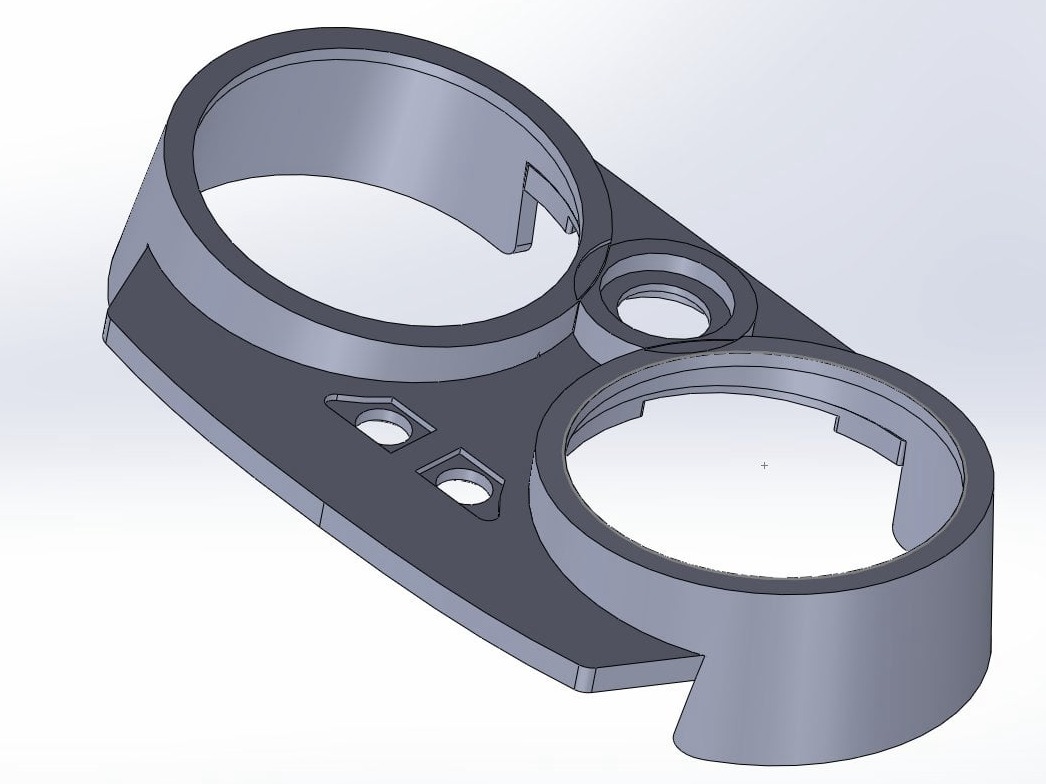

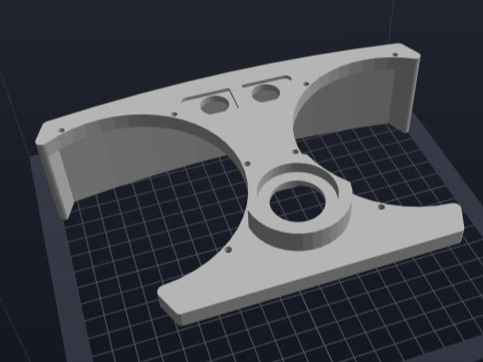

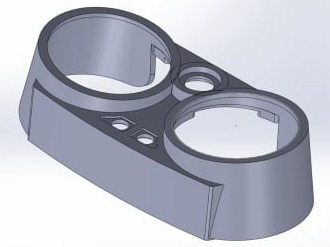

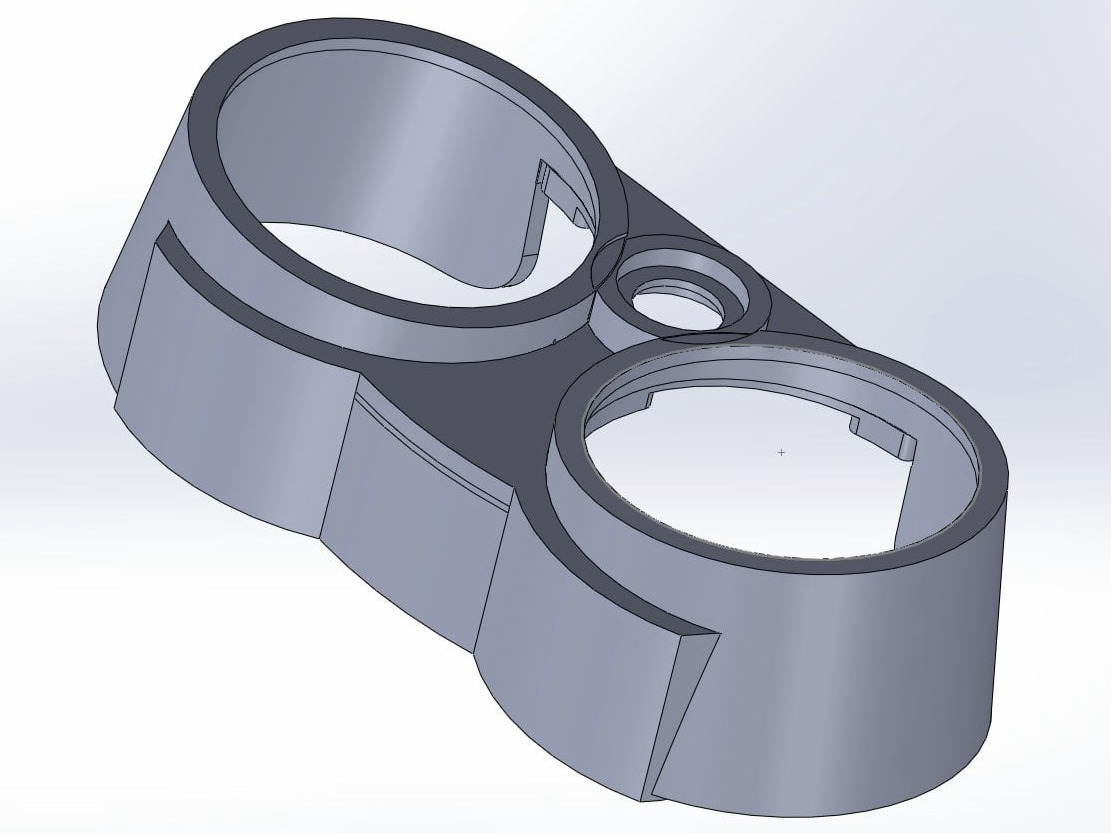

This image shows the completed bezel. It was designed in three parts to enable it to be printed on a standard hobby printer and also to accommodate the angle of the gauges.

The files can be downloaded below and should be printed with a high infill percentage >50% for durability. If there is a requirement to drill the panel for additional switches or an expectation that the edges will need trimming then the infill will need to be 100%.

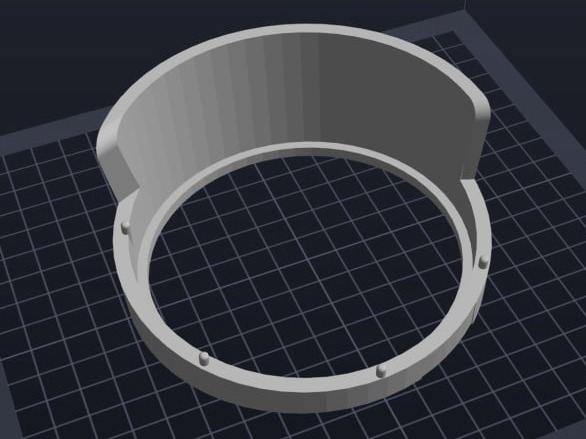

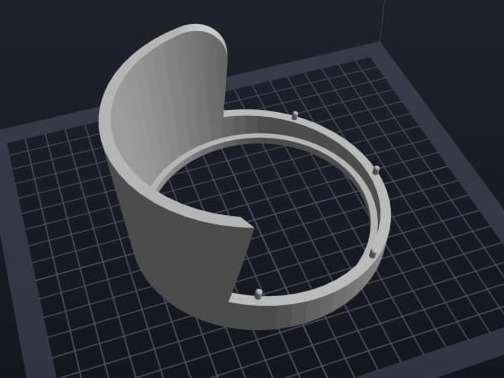

One clock bezel file is provided and the expectation is that two will be printed, but one of them as a mirror of the first.

This design was specifically drawn to fit behind the standard R65 fairing, it featured a taller "forehead" along the top to fill in the gap between the clocks and the fairing.