BMW Airhead Wheel Bearing Replacement

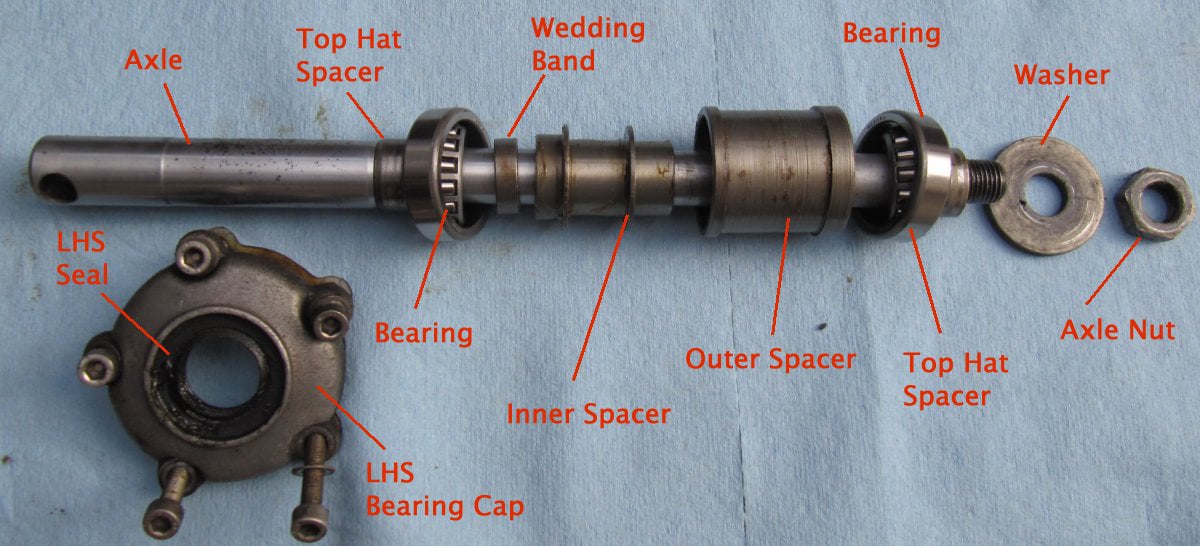

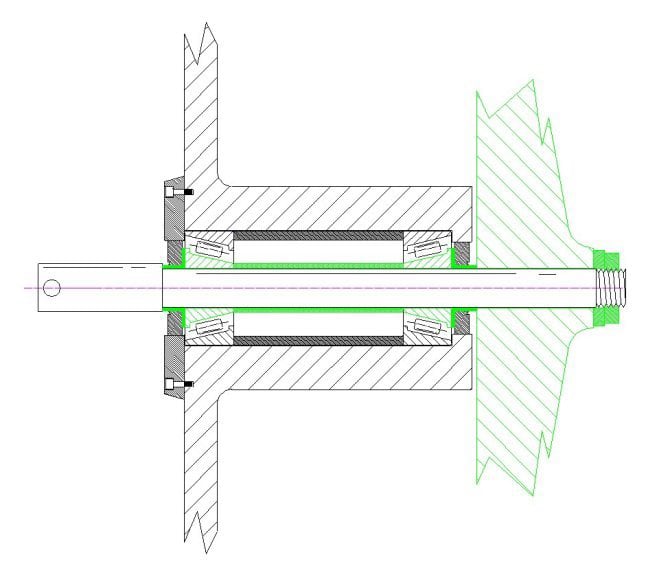

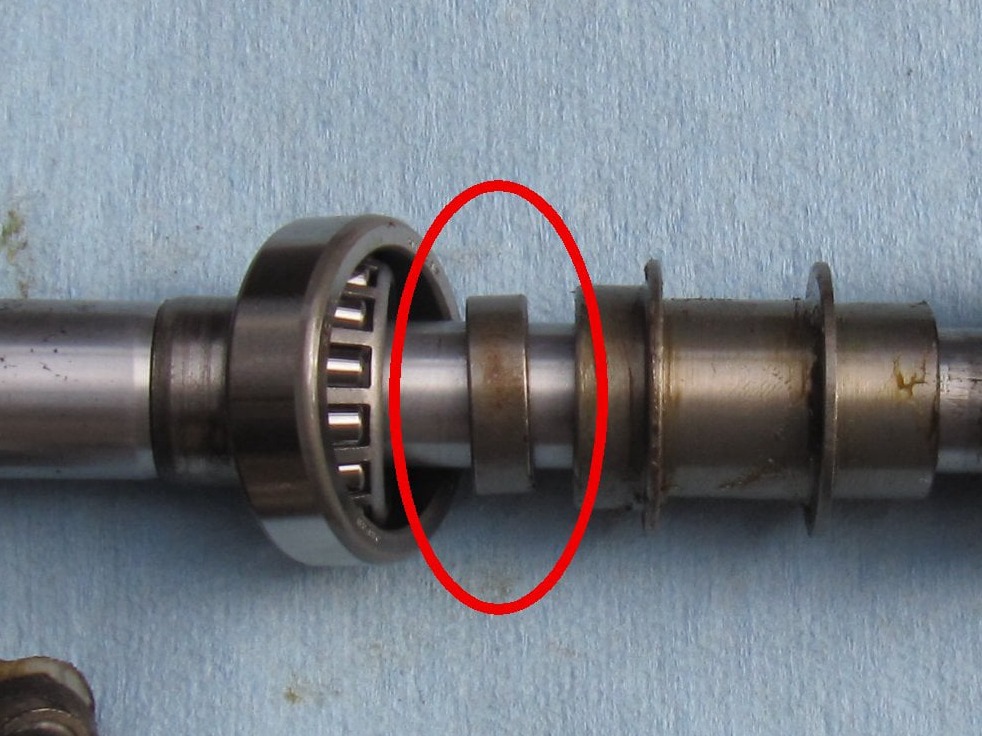

Front and rear wheel bearings on the early airhead BMW's are of the taper roller design. This type of bearing is extremely durable when properly adjusted and maintained.

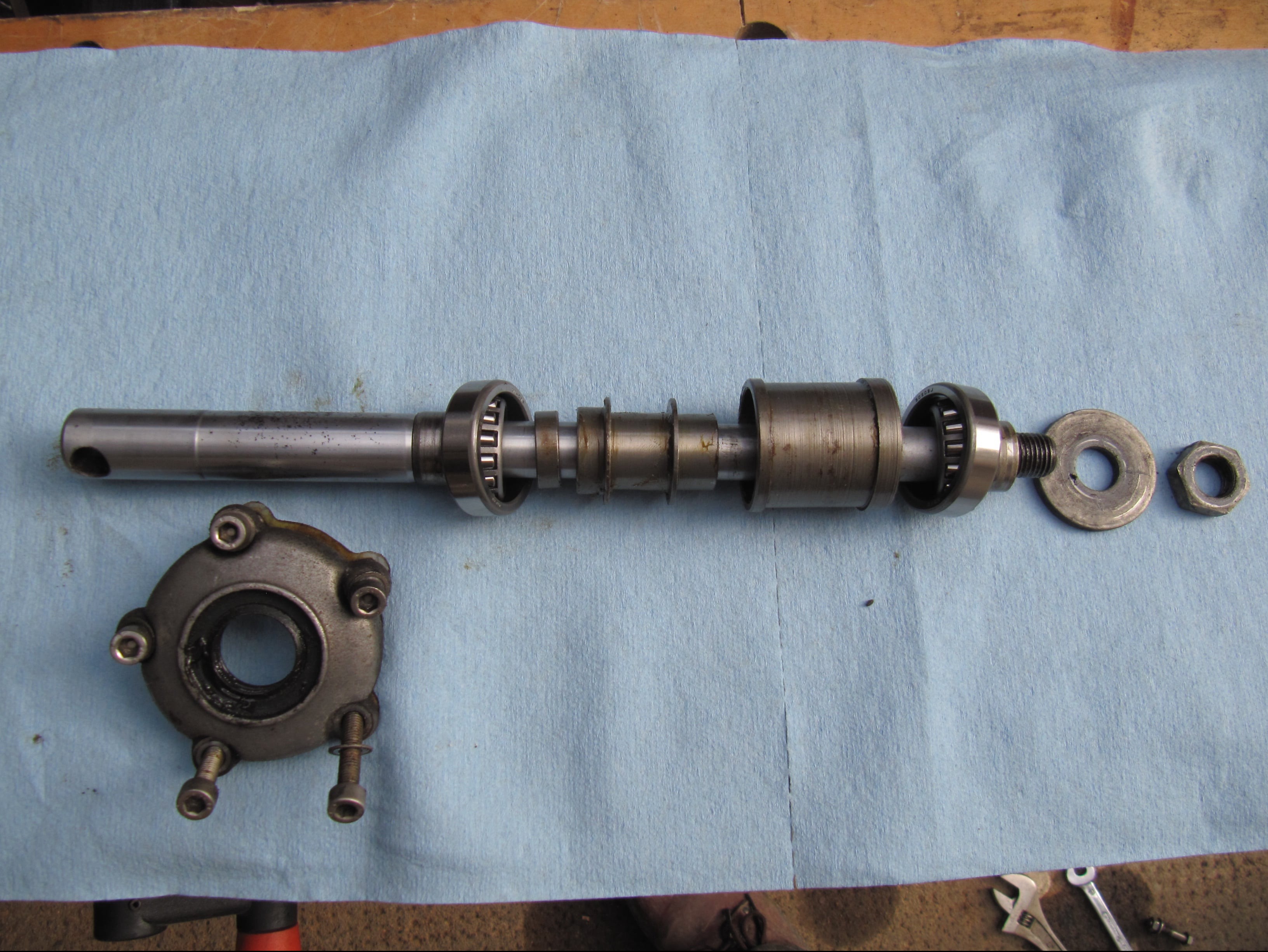

This document details the replacement of the rear wheel bearings and seals.