Replacing push-rod Tubes on the BMW R60/6

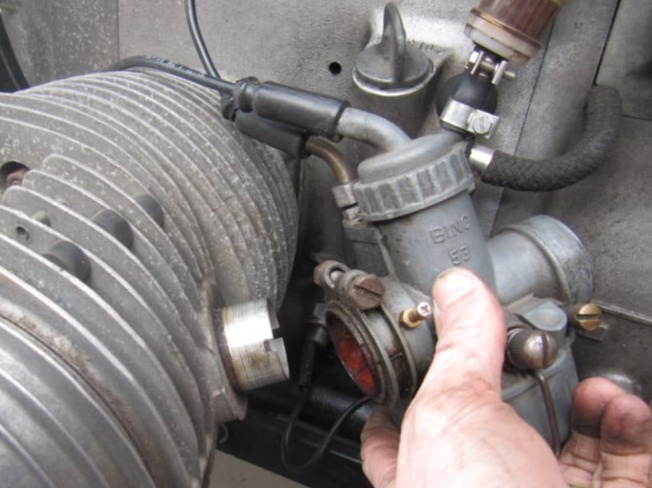

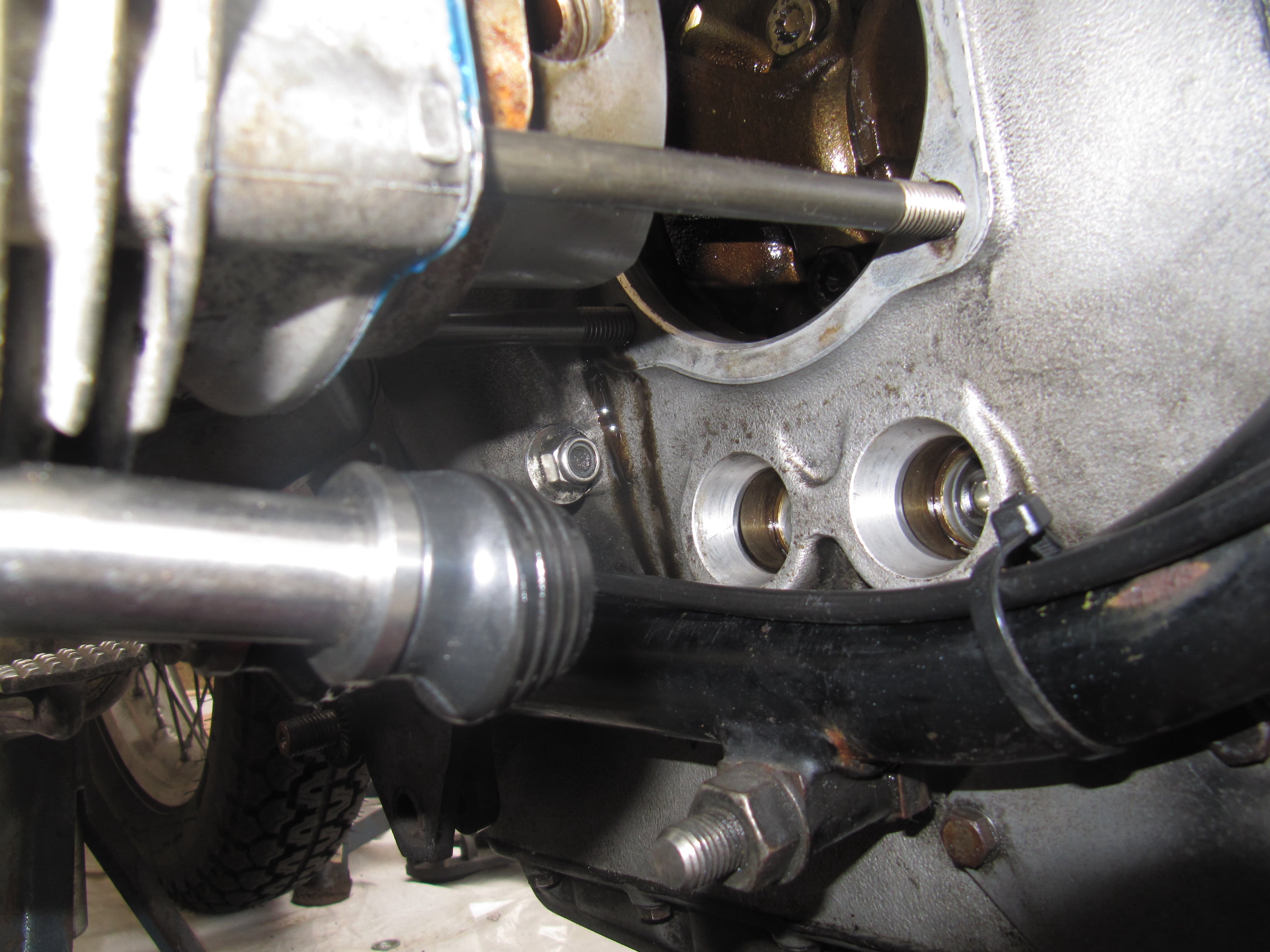

The push-rod tubes on the classic BMWs have a hard life, running at elevated temperatures in the water and salt spray from the front wheel.

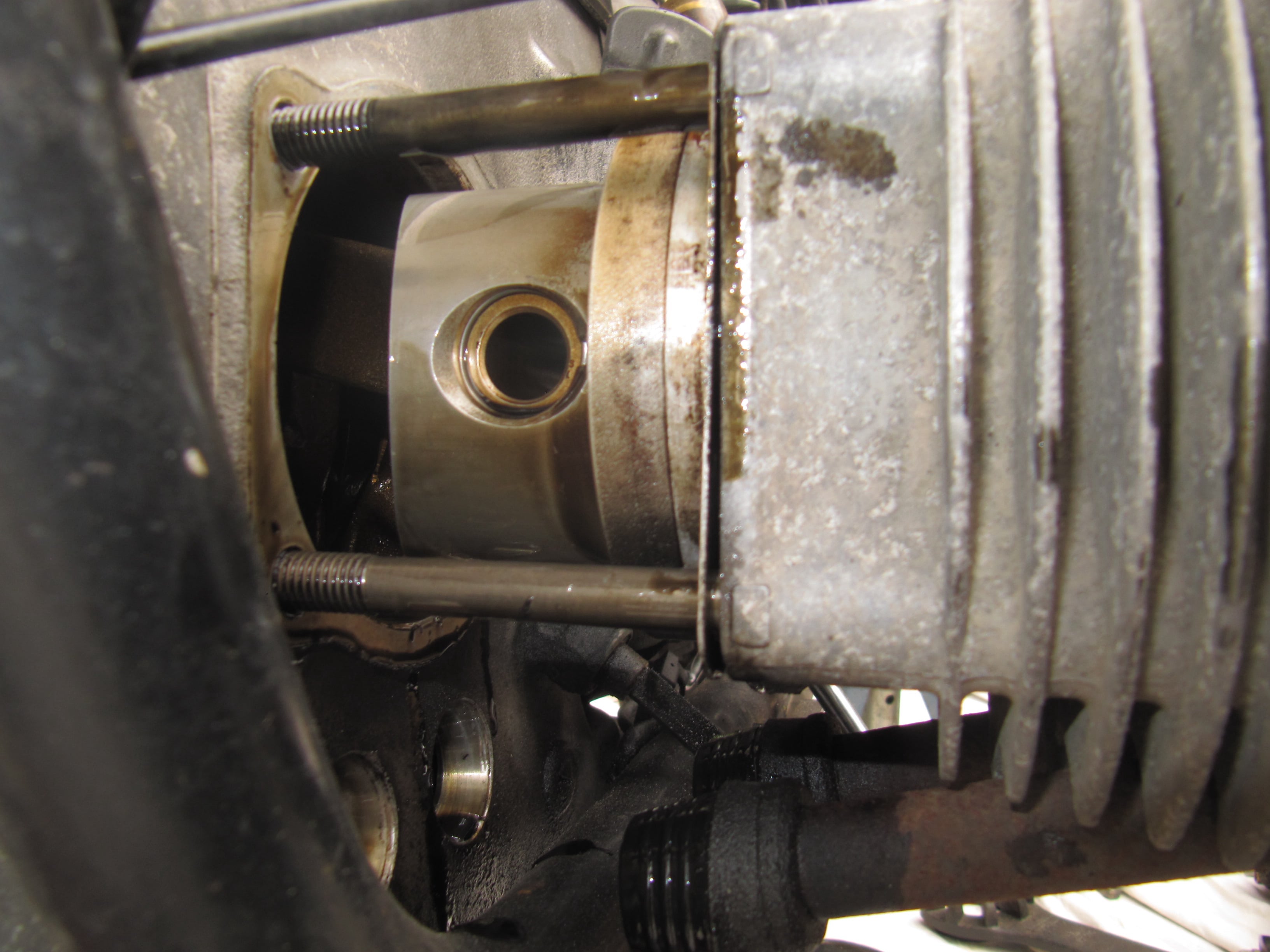

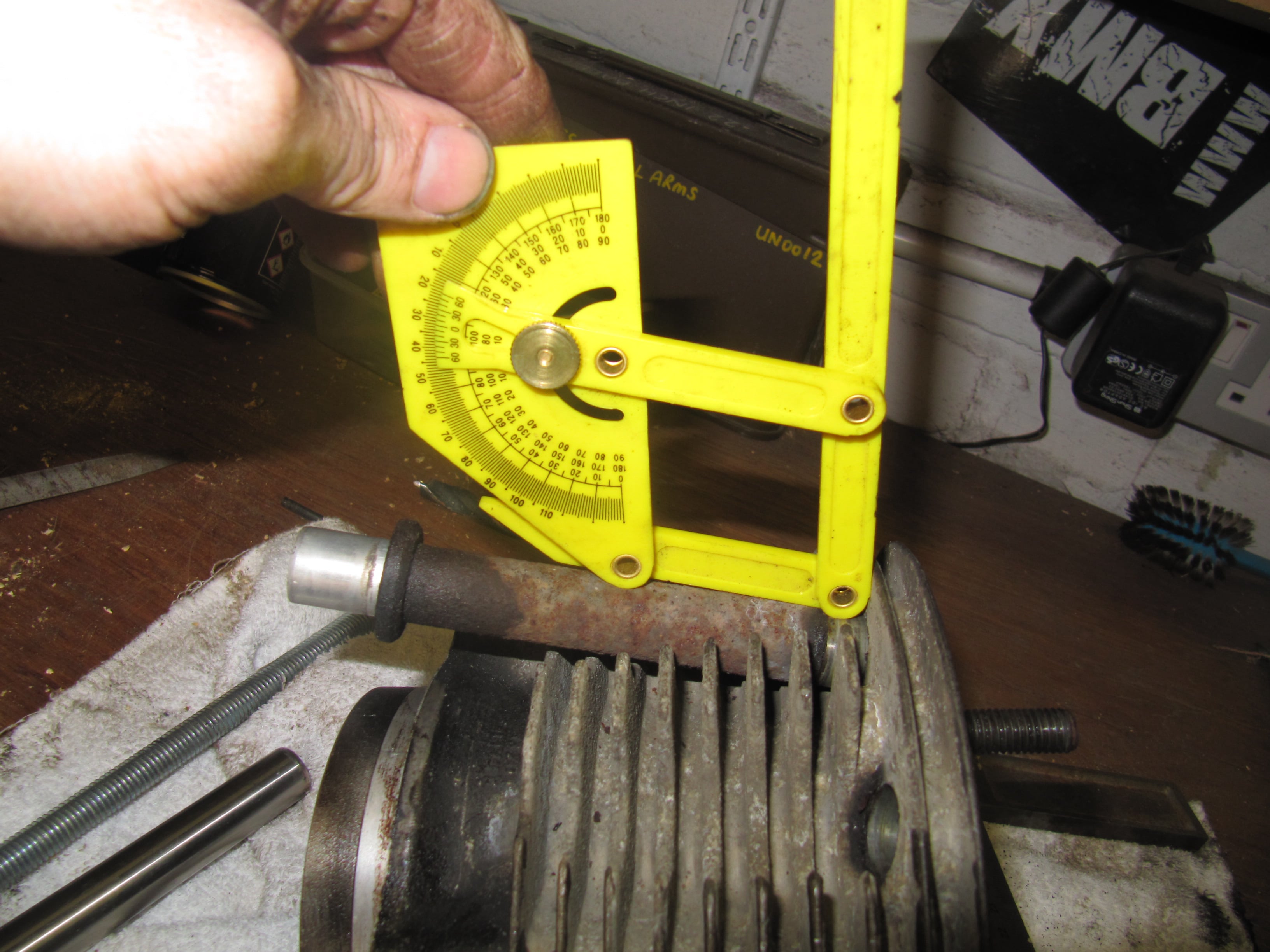

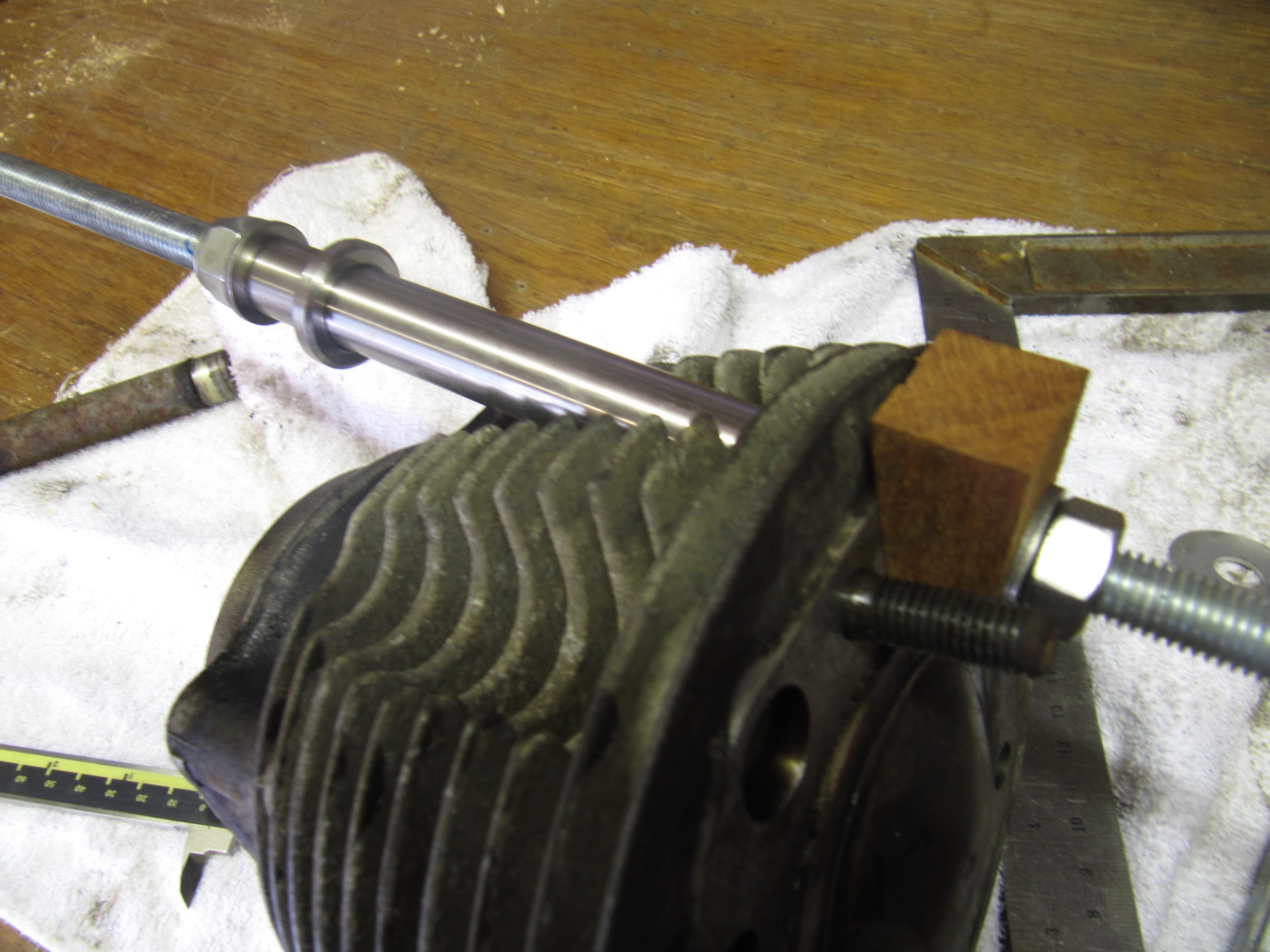

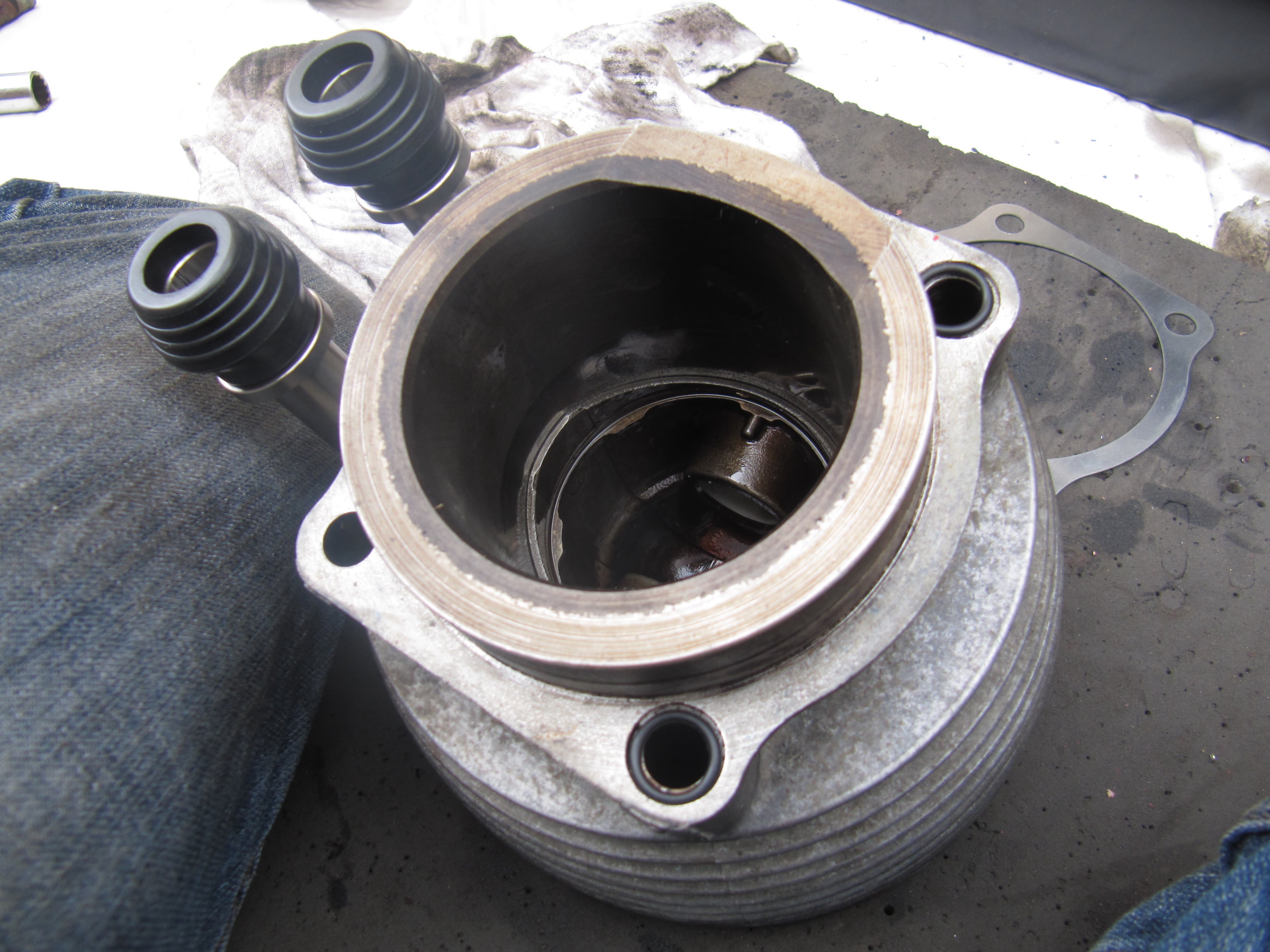

Stainless steel after market items are available and this page shows how they were fitted.

If just the rubber seals are the be replaced then this can be done using a similar process with the difference noted in the text.