BMW Airhead Head Bearing Replacement

Replacing the steering head bearings on a BMW airhead requires disassembly of the fork assembly and extracting the bearing cups from the head can be difficult.

On reassembly the forks need to be aligned to avoid stiction in the suspension.

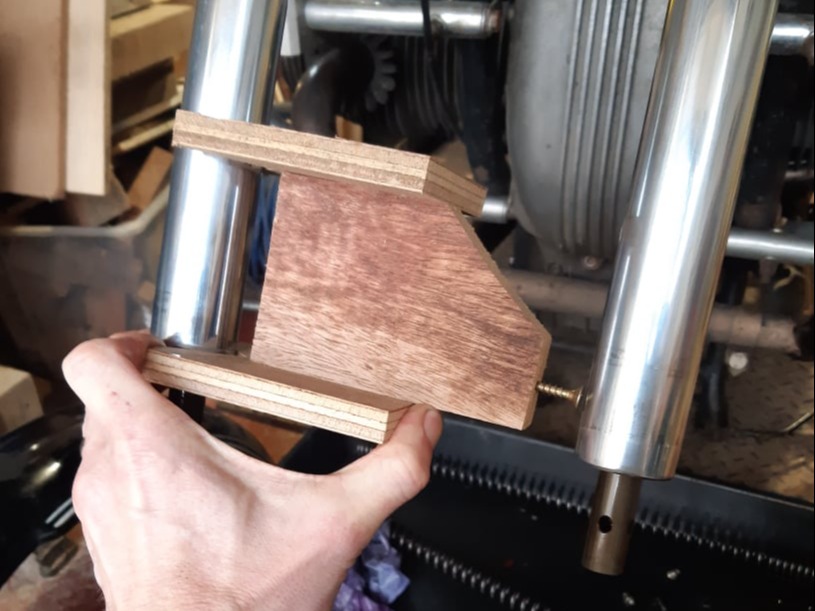

The process described for the fork alignment here is simple and quite crude, but worked on this old machine with worn and used parts. The final result was suspension that behave smoothly and satisfactorily.