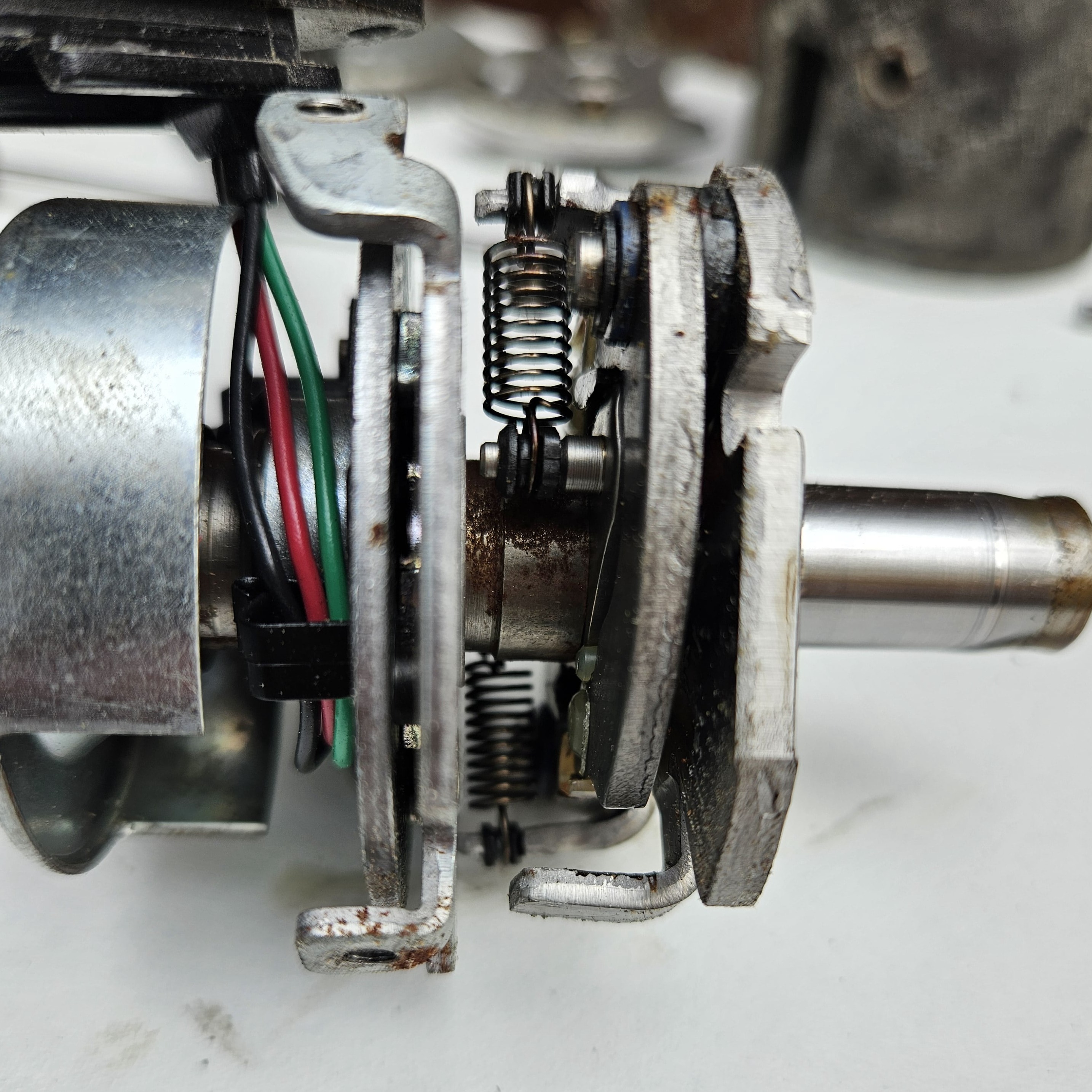

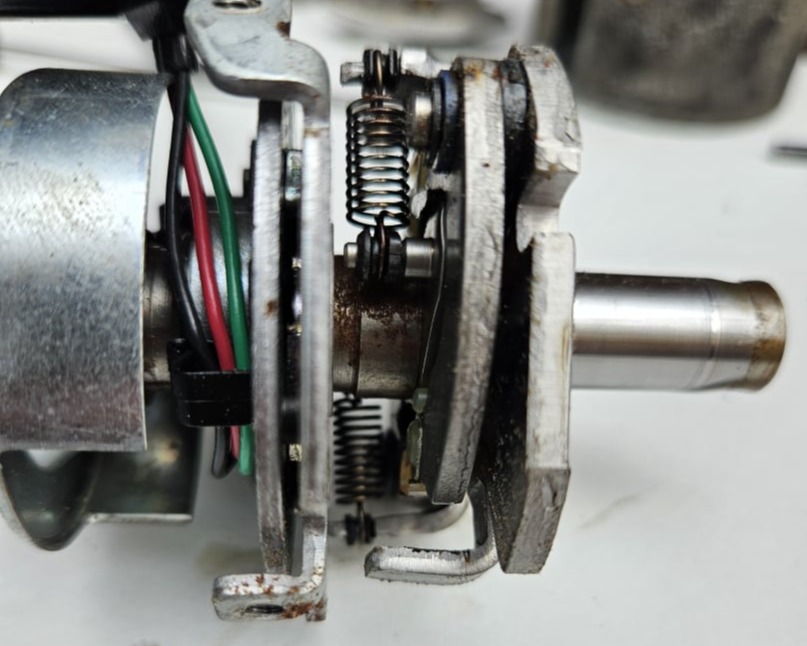

Replacing Springs on the BMW R65 Advance Mechanism

The R65 has electronic ignition, but with mechanical advance controlled with centrifugal weights. A fast engine idle after a highway run can be a symptom of the return springs being stretched or tired.