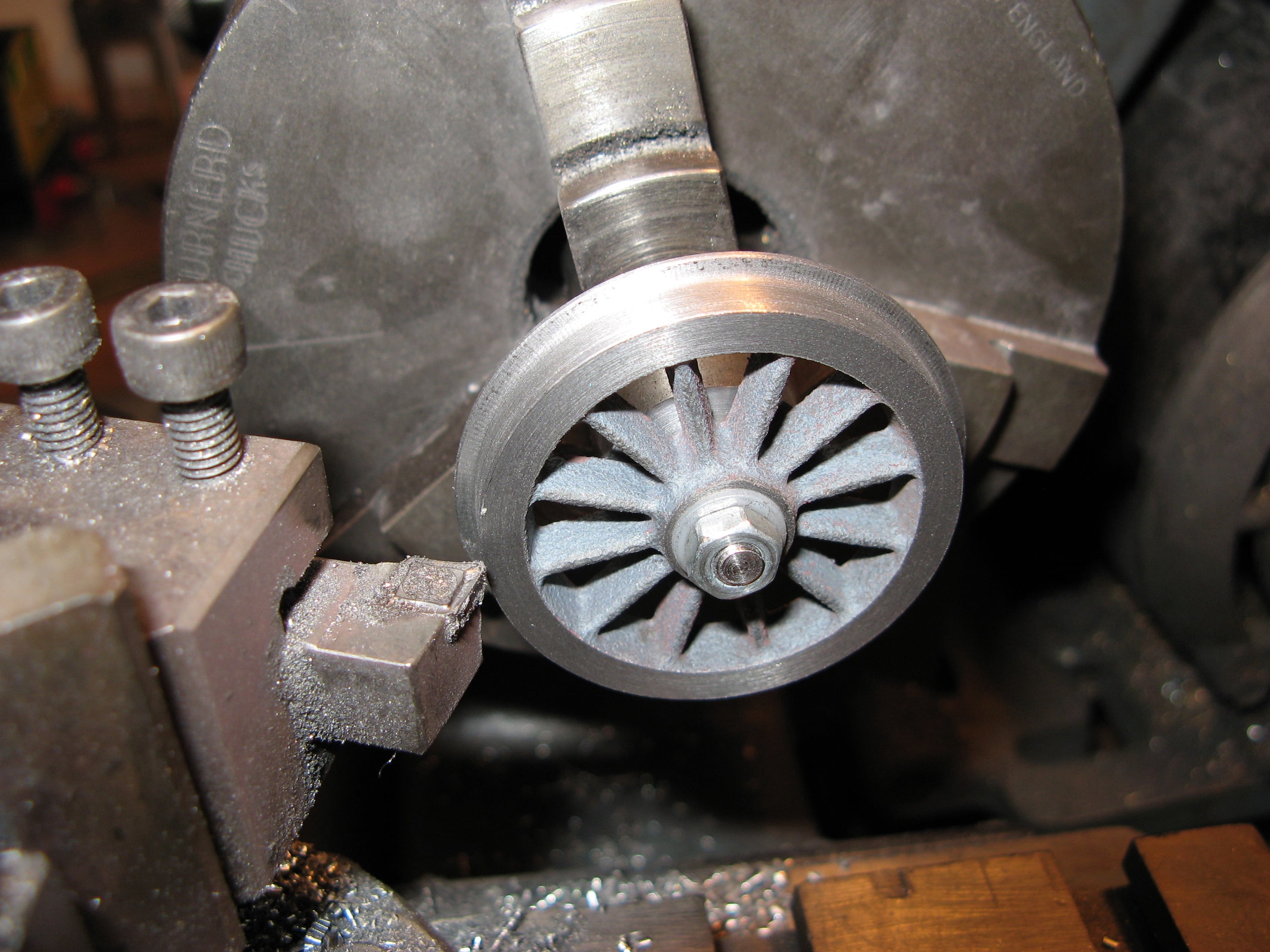

Turning Locomotive Wheels

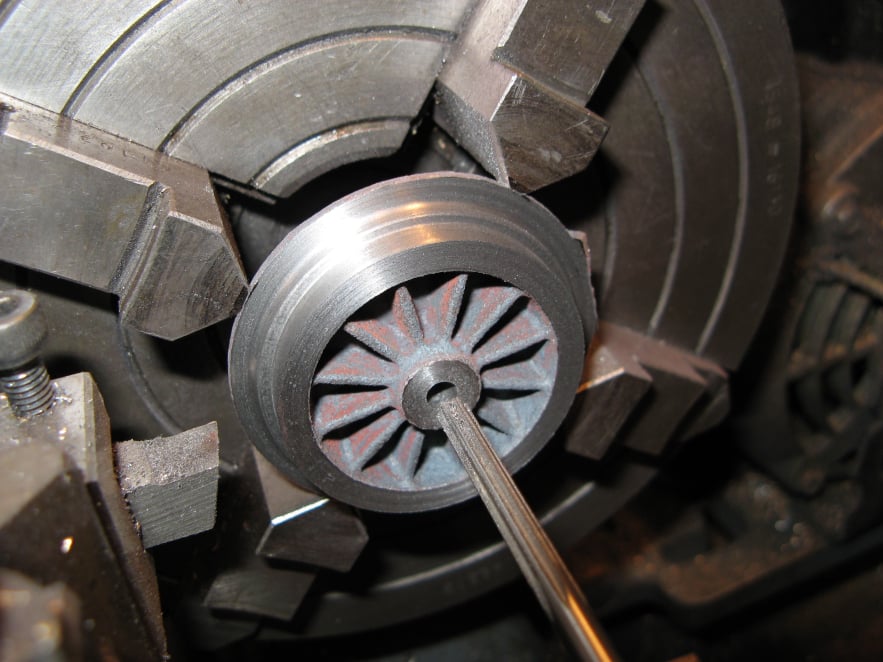

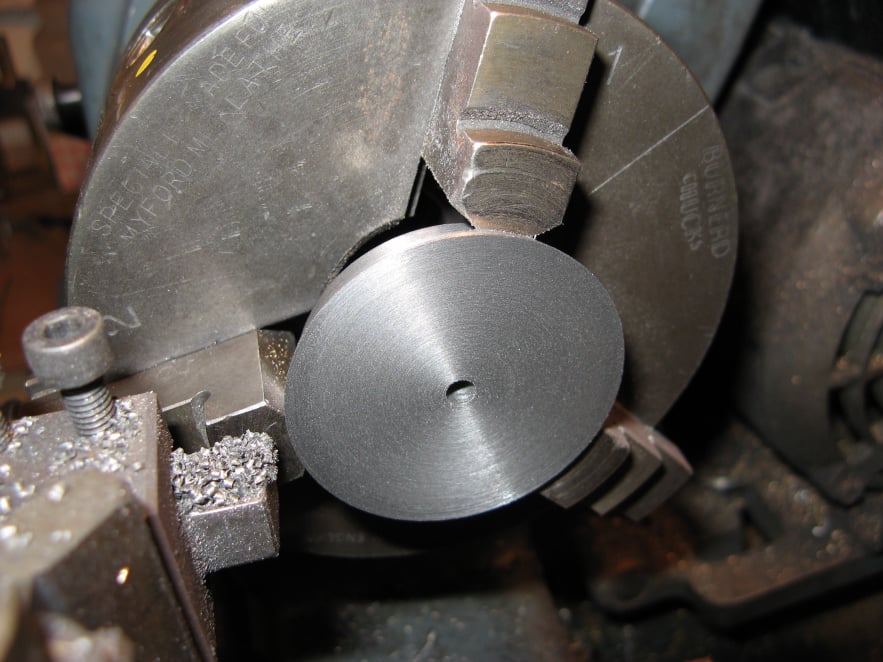

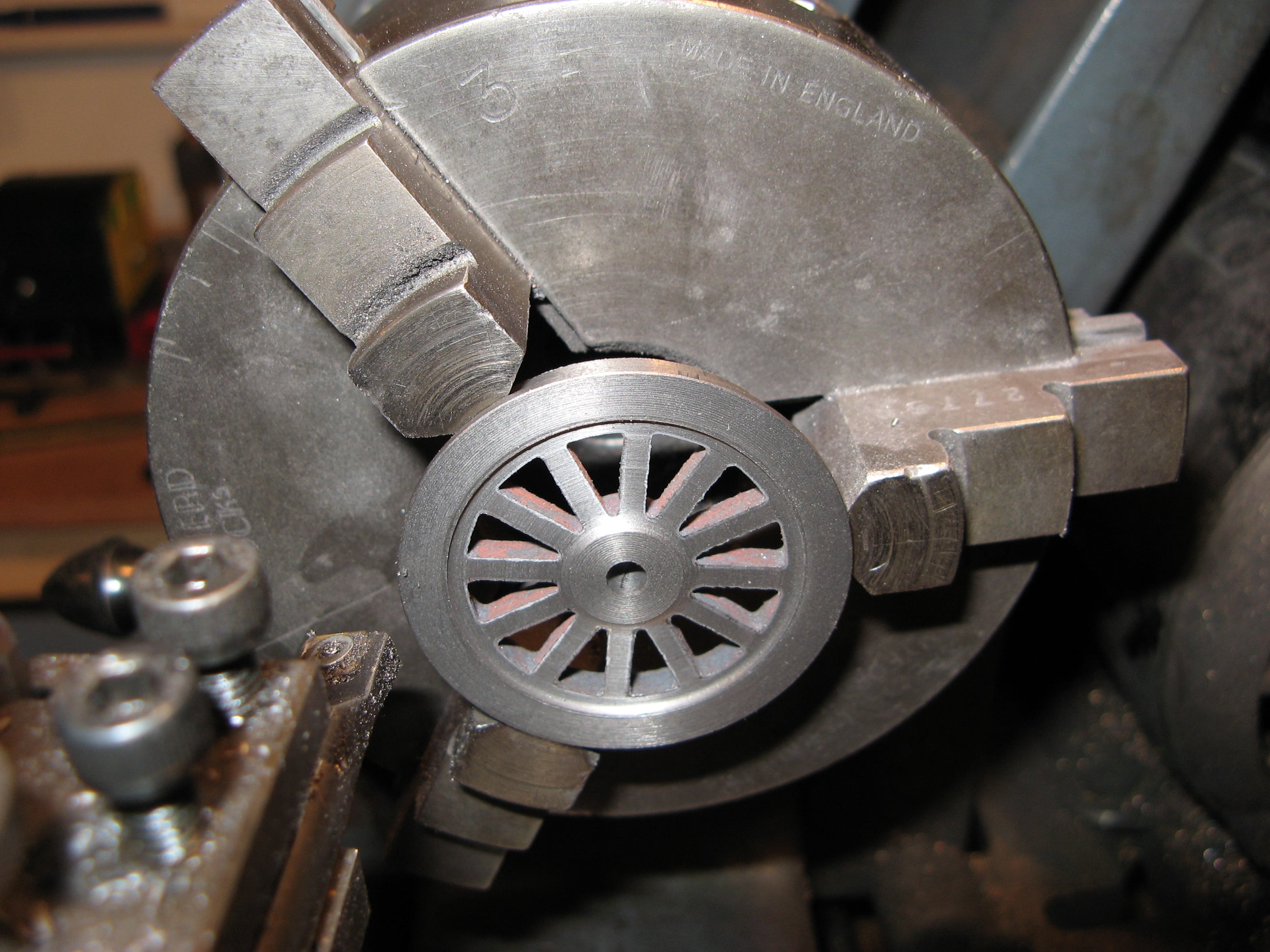

This page describes a process used to turn locomotive wheels to the identical sizes and with true running surfaces.

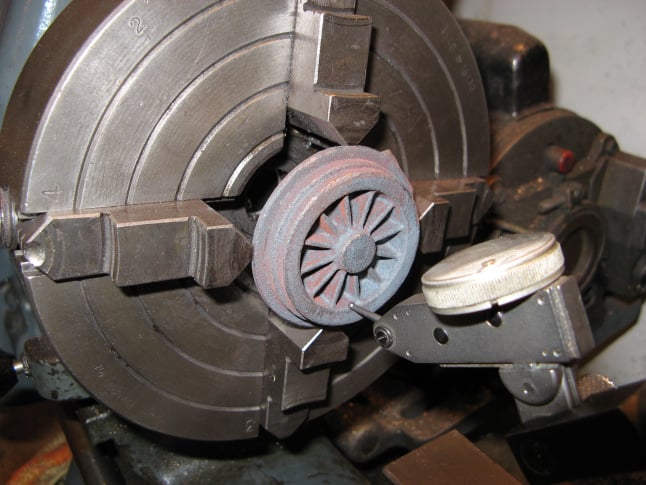

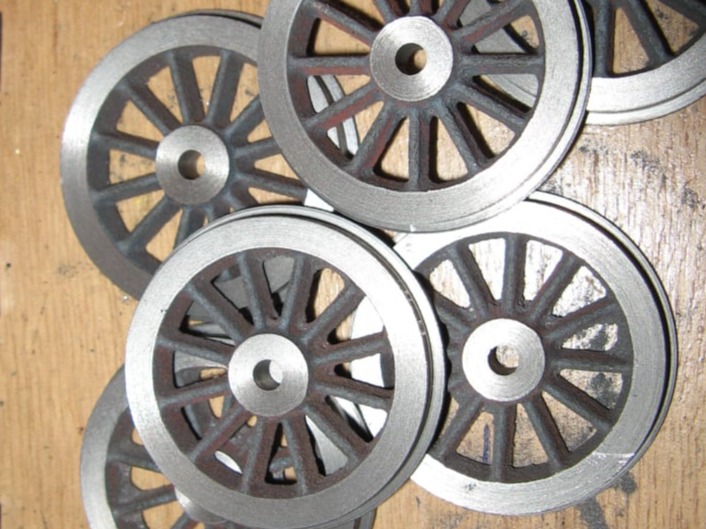

The wheel used in this example was a small Gauge 1 tender wheel about 40mm diameter but the same process can be used on wheels of any size.

When machining a set of wheels it is best if all wheels complete each step, before moving on to the next process. This ensures that the wheels in the set, have the same dimensions as each other.

The same approach can also be applied to ensure a flywheel runs properly true.