Geepstar Electrics

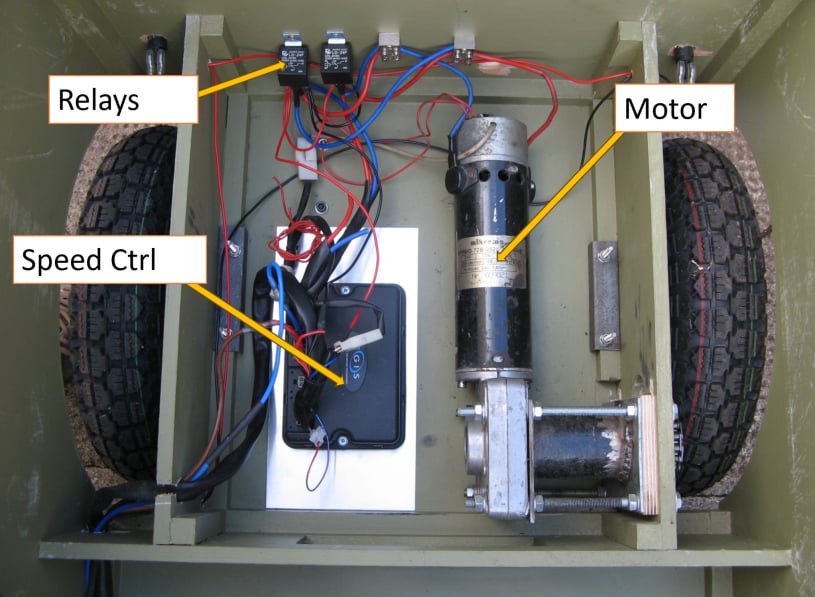

The basic electrics for the Geepstar were lifted from a scrap mobility scooter and were modified to suit.

The donor scooter was a Karelmar 8mph model. Containing two 250w motors. The scooter had a forward / reverse control and another dial to set the maximum speed. Other features included a slow speed setting, freewheel control, auto-parking brake and lights.

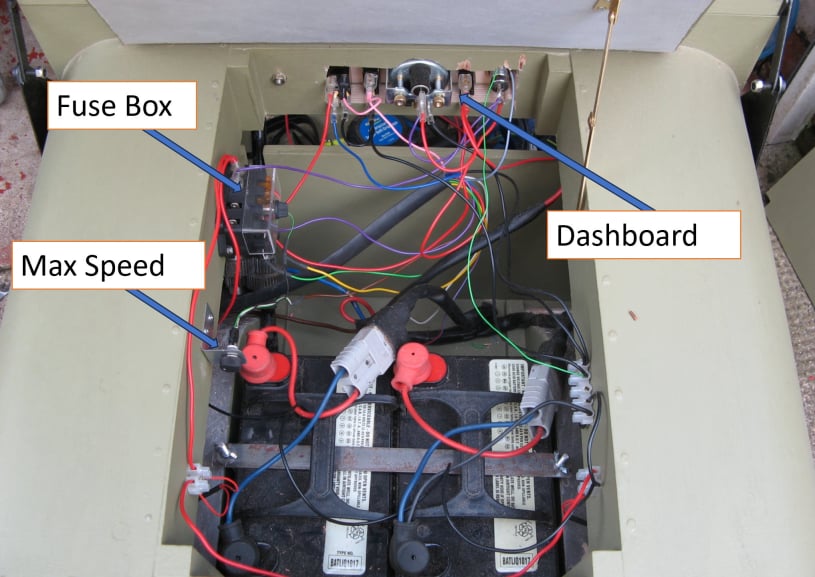

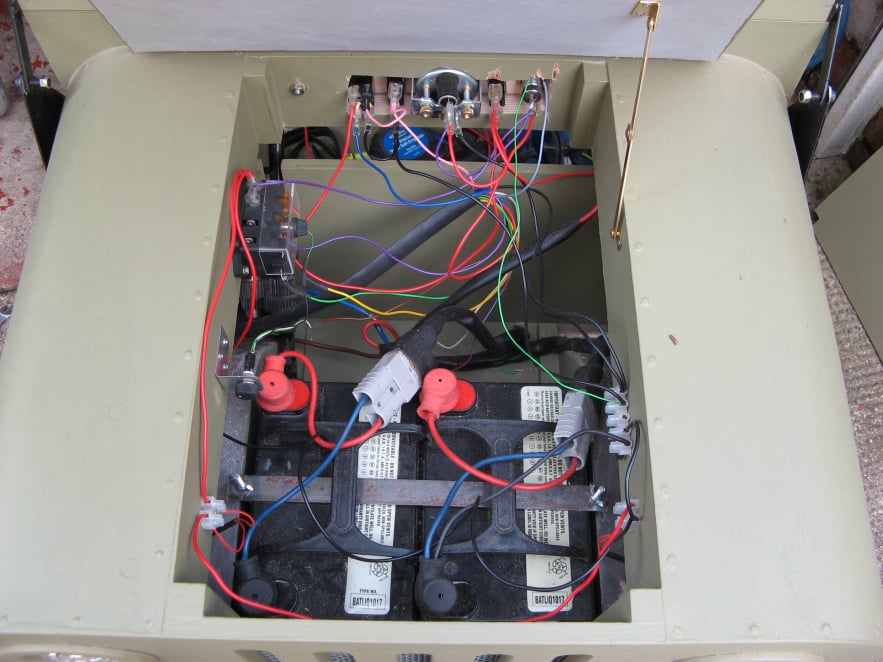

Originally the scooter was controlled by a "wig-wag" mechanism. This was a rocking bar on the handlebars, pulled by the right hand to go forward and the left hand to go backwards. This would need modifying so the speed could be varied by a pedal and the direction via a switch. The Geepstar wiring would also need to include the necessary fuses and an isolator switch to cut the power to everything.