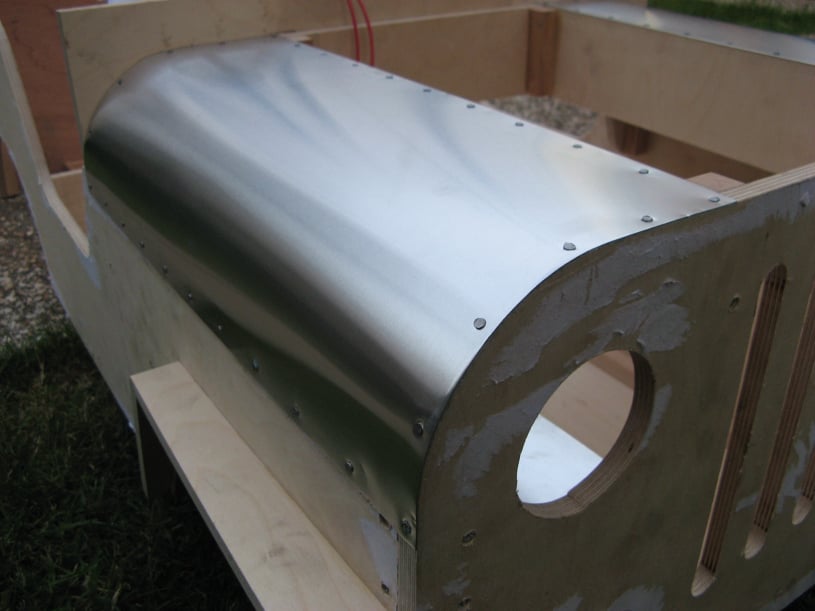

Geepstar Bodywork.

The Geepstar bodywork plans were printed full size so they could be stuck to the chosen sheet material and cut with a jigsaw.

The Geepstar is a monocoque construction with metal fabricated parts. The body was made from good quality 12mm plywood, with some aluminium panels.