Using the Fixed Steady on the Lathe

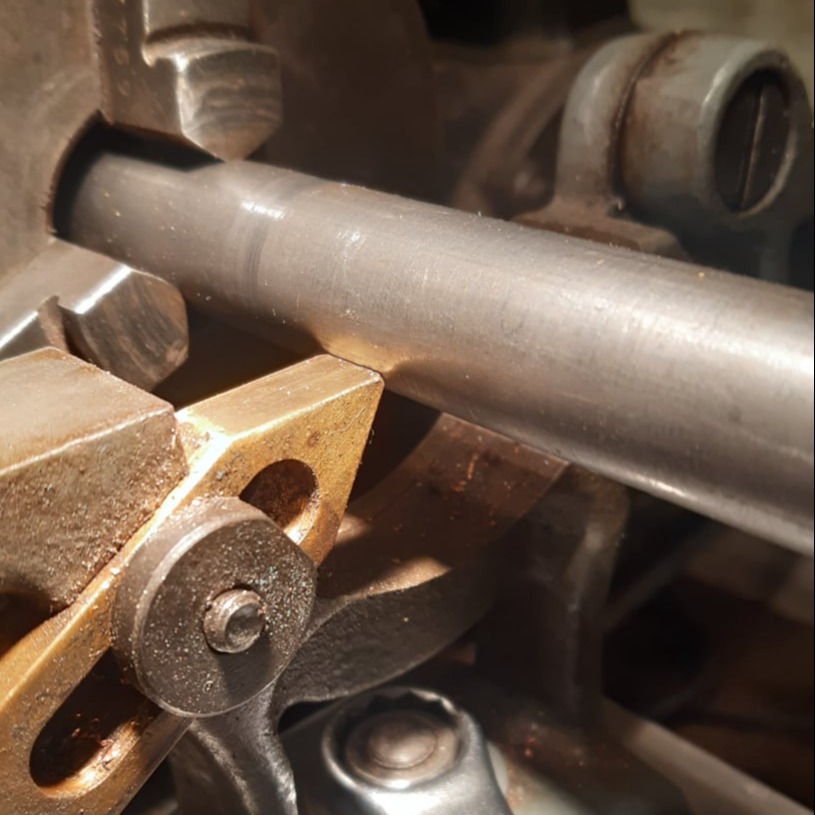

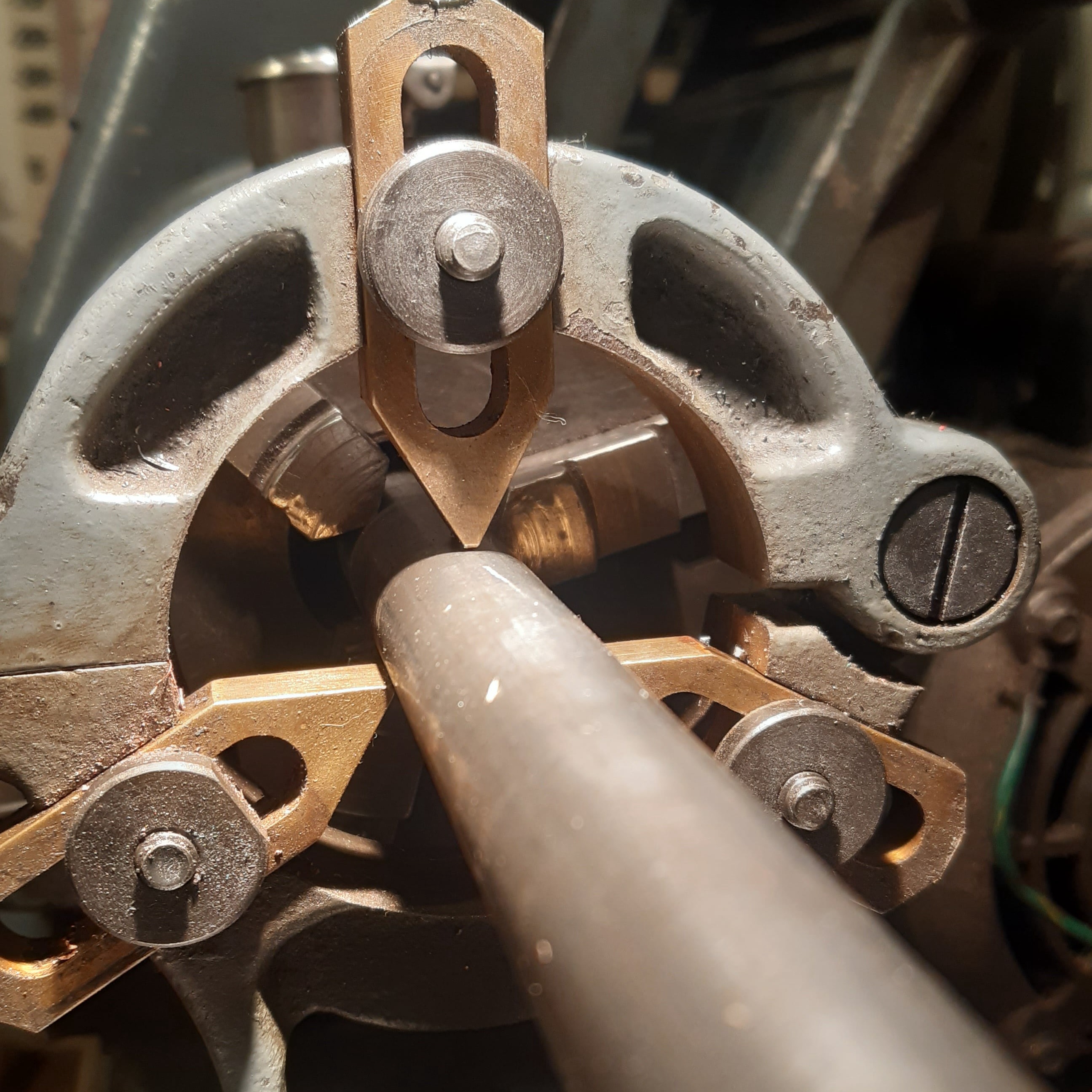

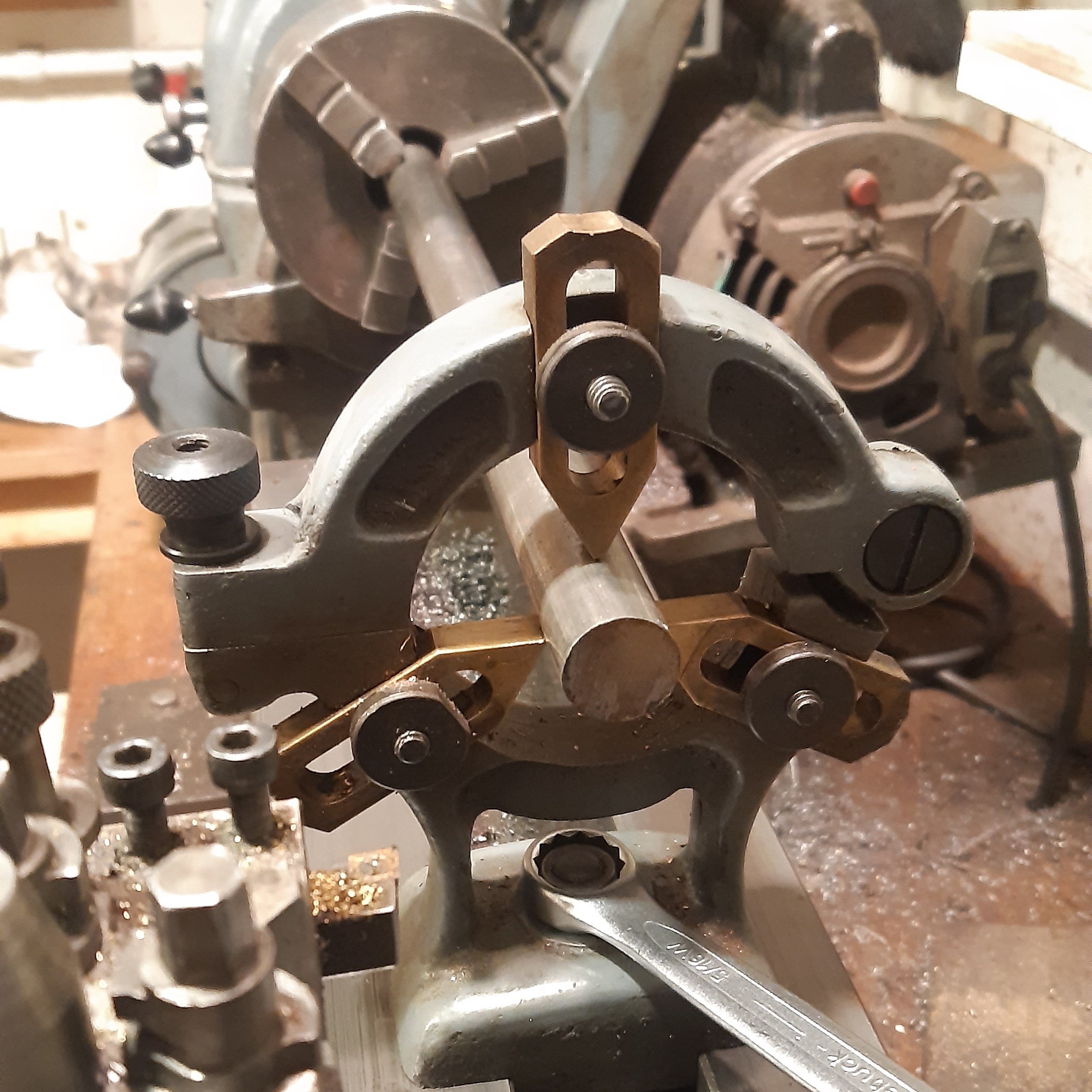

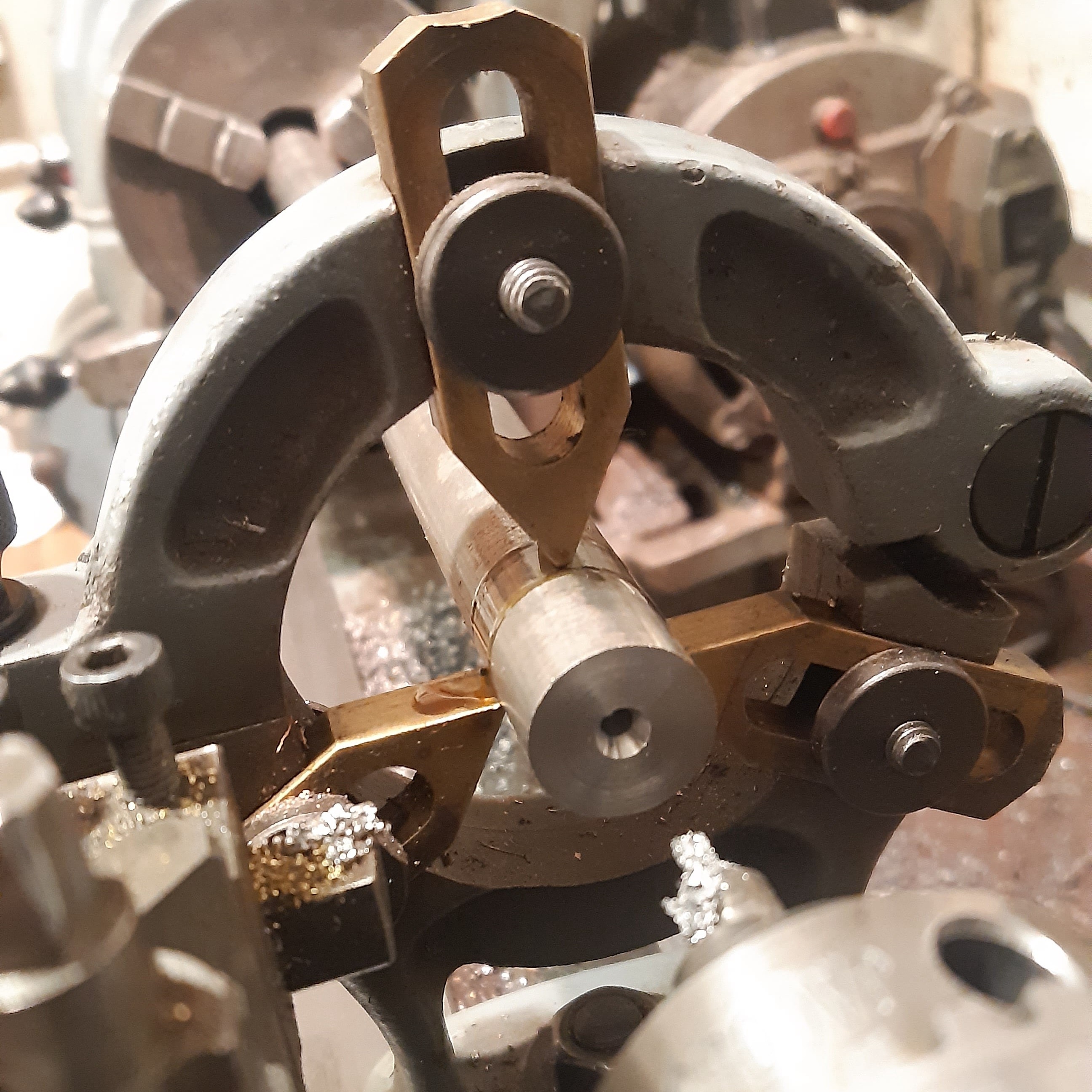

The fixed steady can be used to support work that is long. Small diameter work is best pushed into the headstock tube so the operator can work near the chuck, but if the diameter is too large, the fixed steady can be used.

The method shown here assumes the bar is reasonably straight. This allows the fixed steady to set up near to the chuck and then transferred to the far end of the bar to provide support for the machining operations.