CAD and Model Engineering

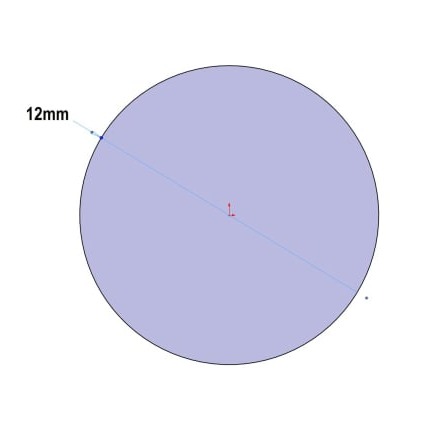

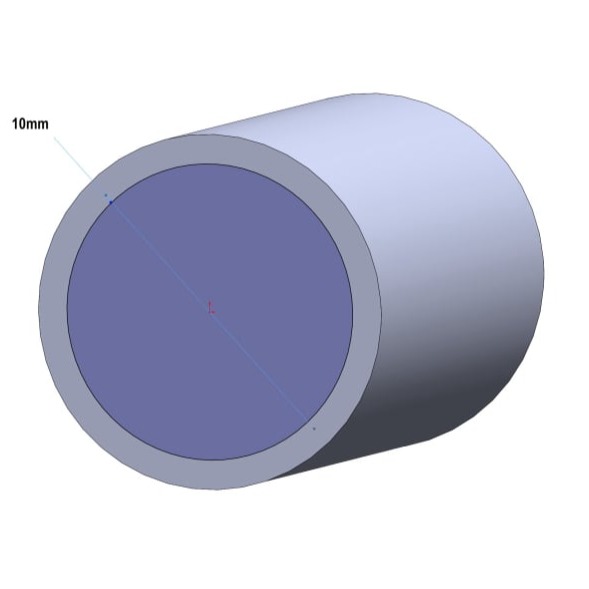

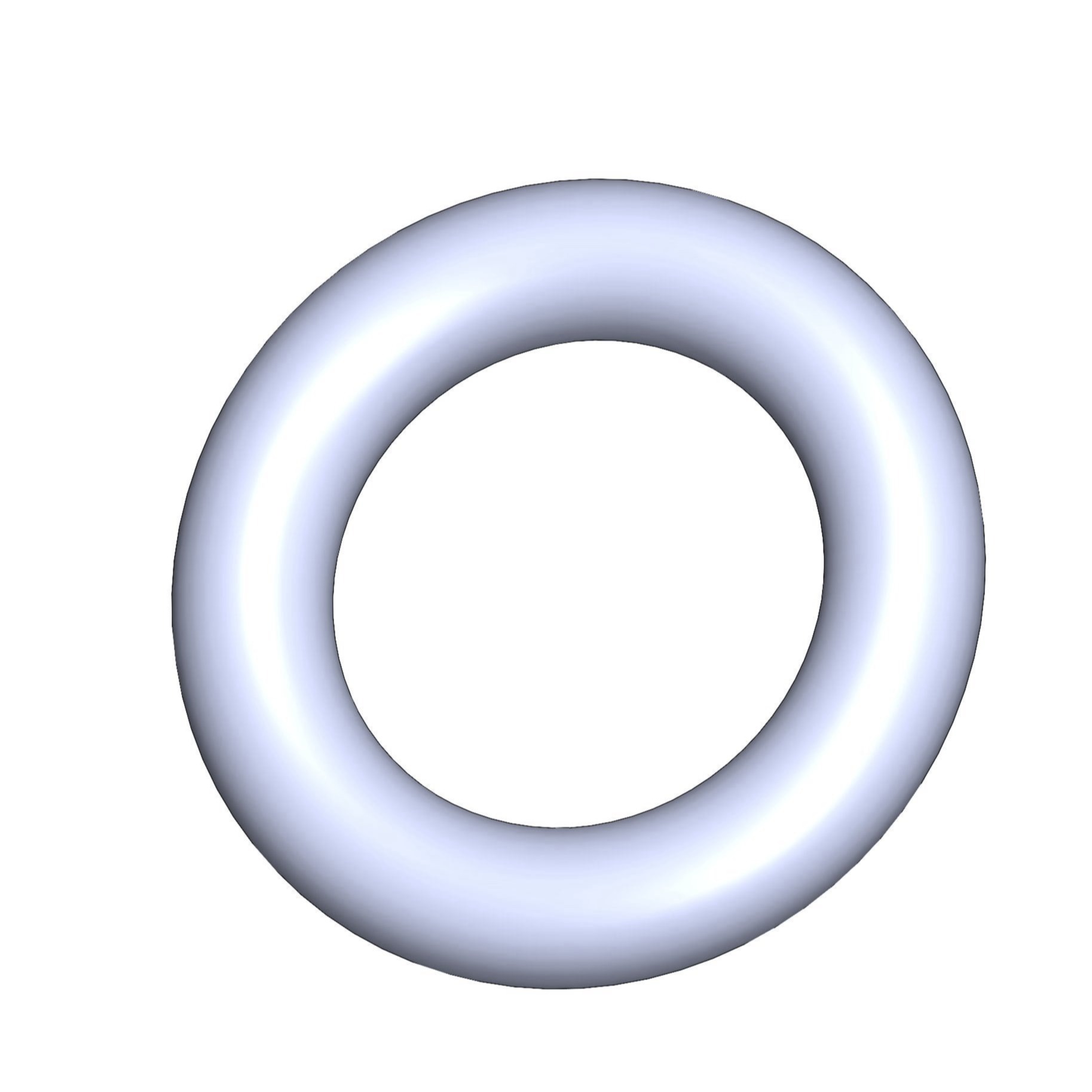

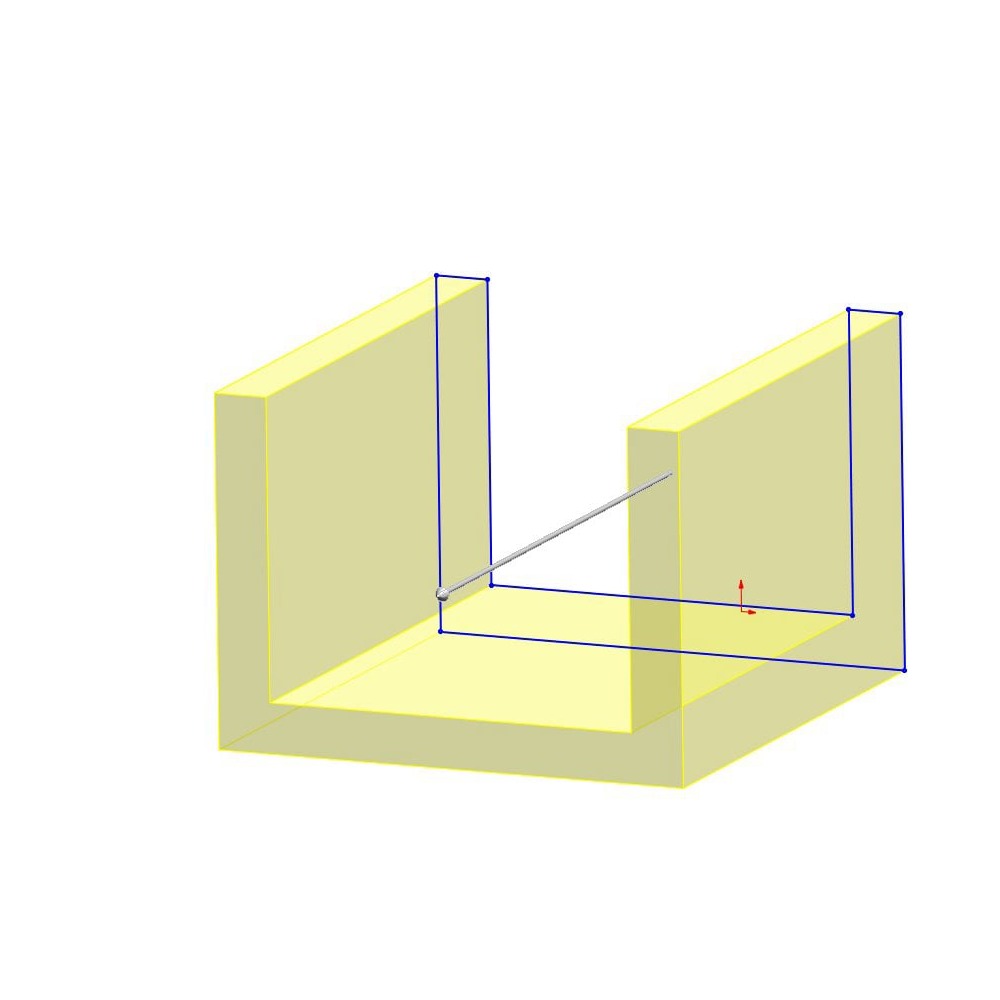

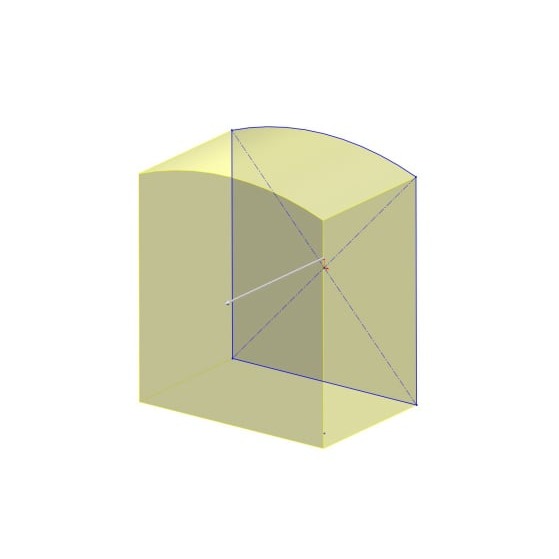

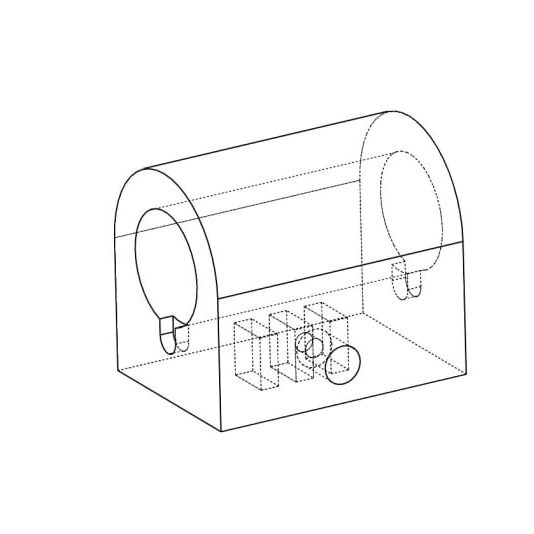

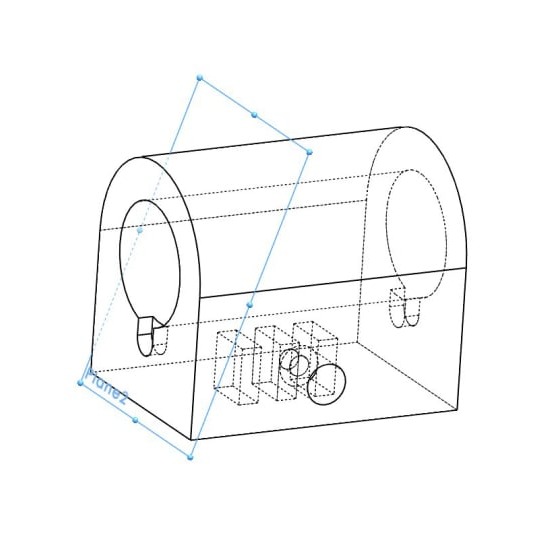

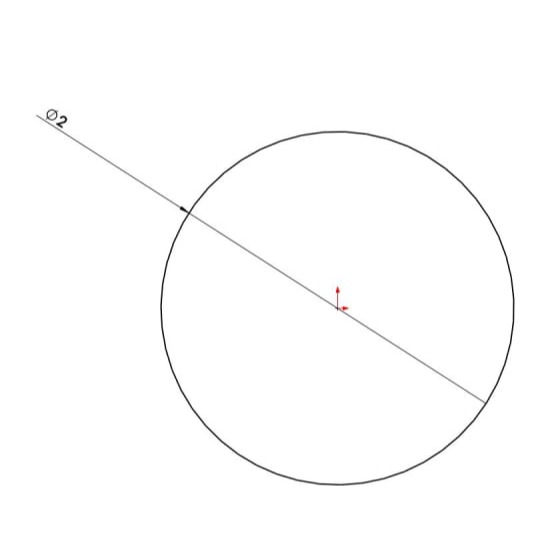

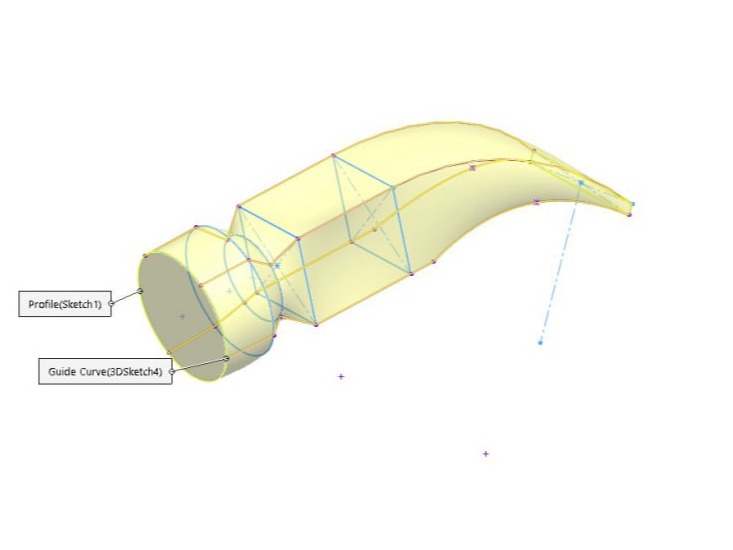

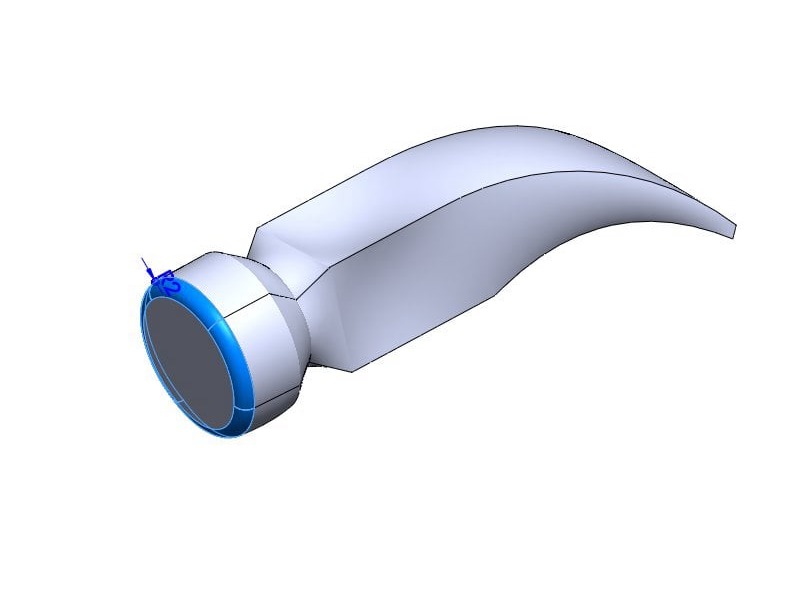

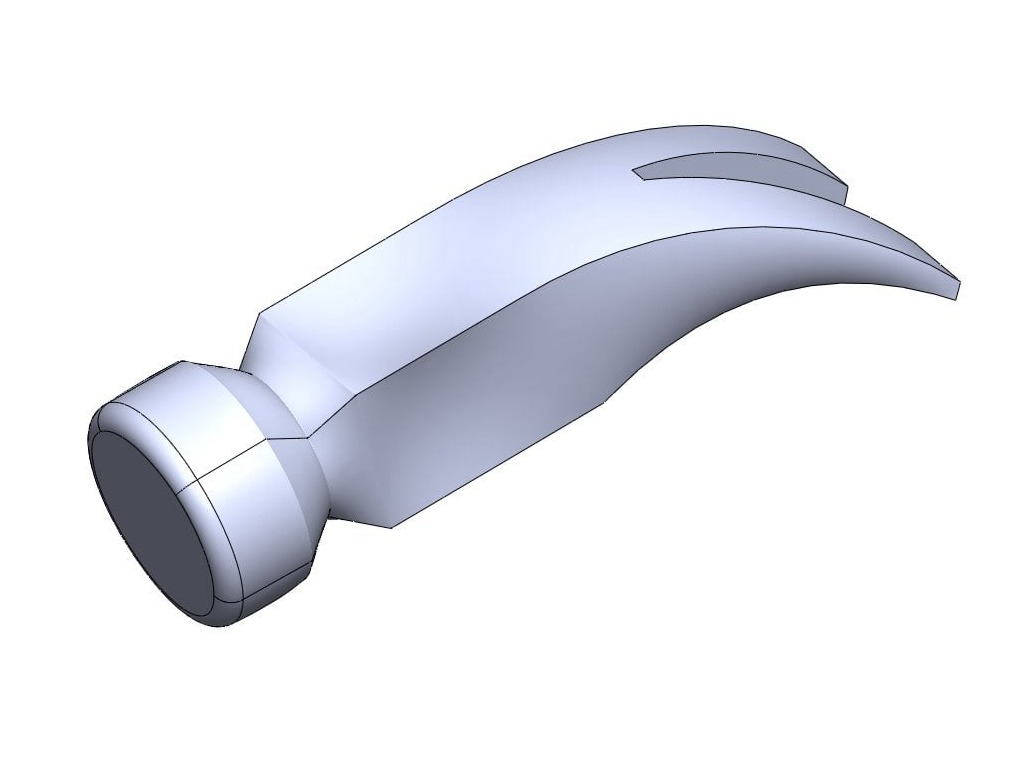

This page talks about Computer Aided Design (CAD) and how it can be useful for model engineers and hobbyists to design parts for projects. As well as part design, CAD can be used to check the fit of parts, to check for clashes in moving assemblies, to export 2D drawings for manufacture and to create files suitable for 3D printing.

CAD softwares are constantly evolving and new options appear, but at the time of writing this page (2023) some free options are; Creo elements express, Onshape, Sketchup, freeCAD, Fusion 360, Solid Egde and NanoCAD.