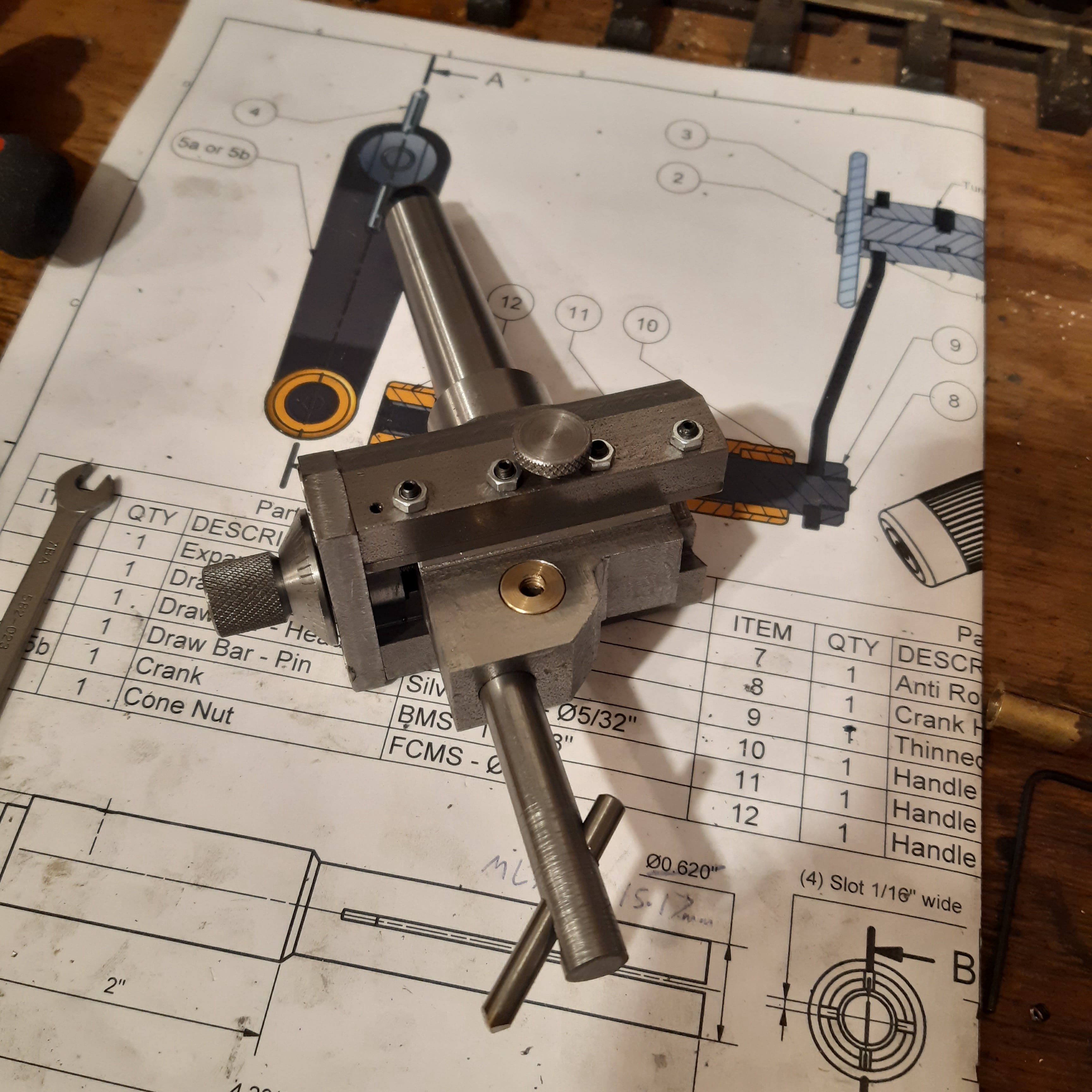

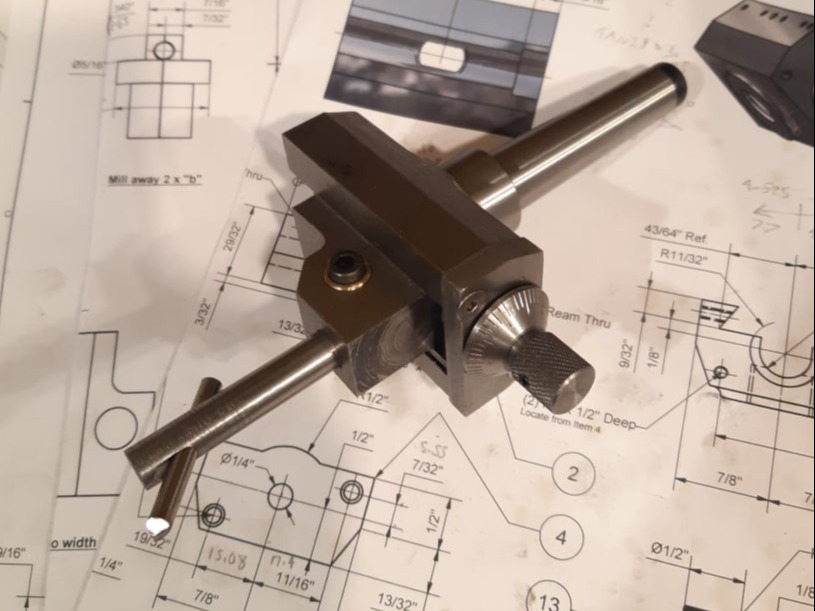

Making a boring head

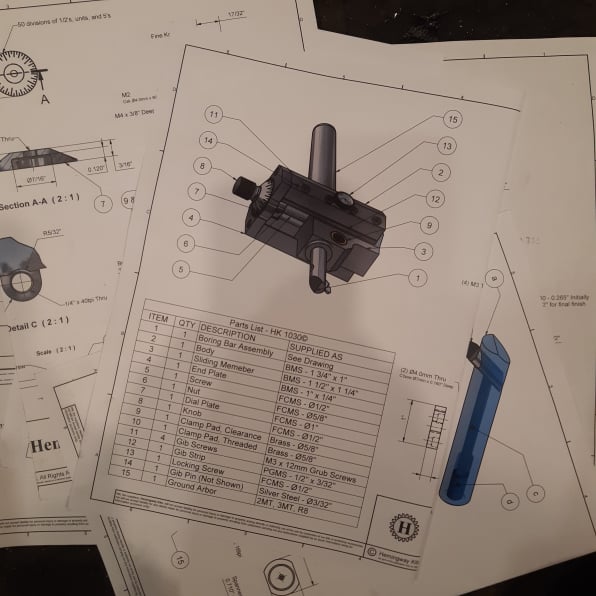

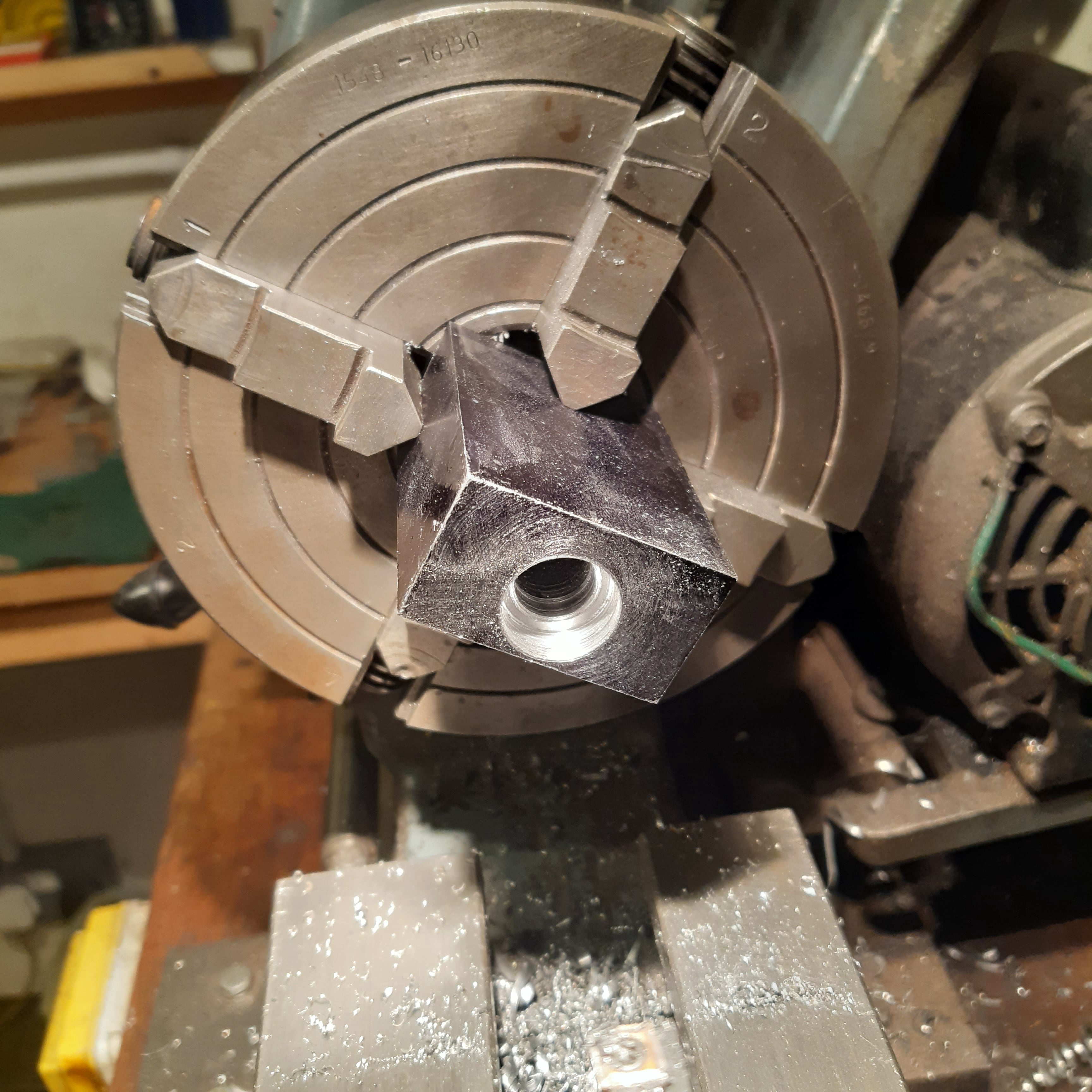

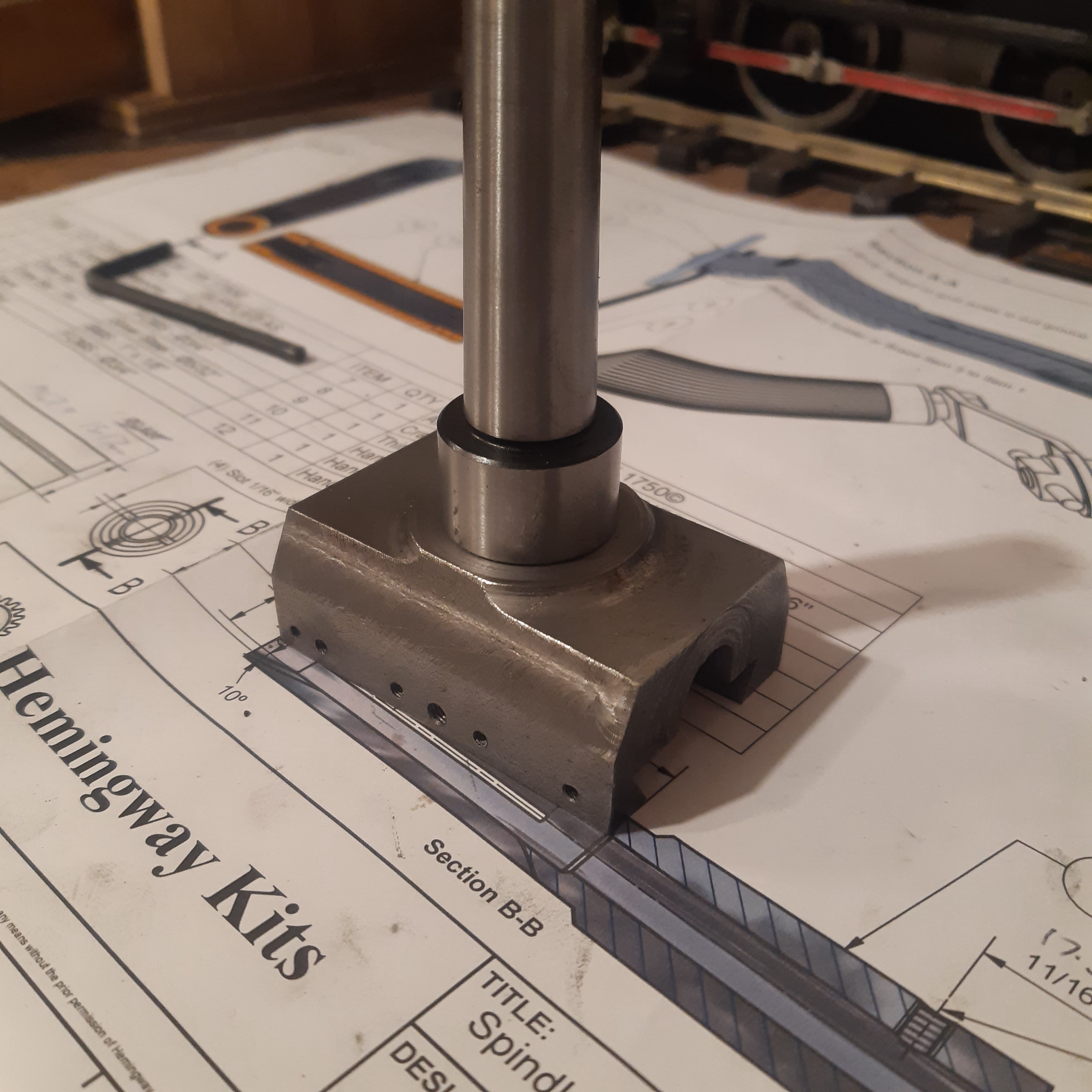

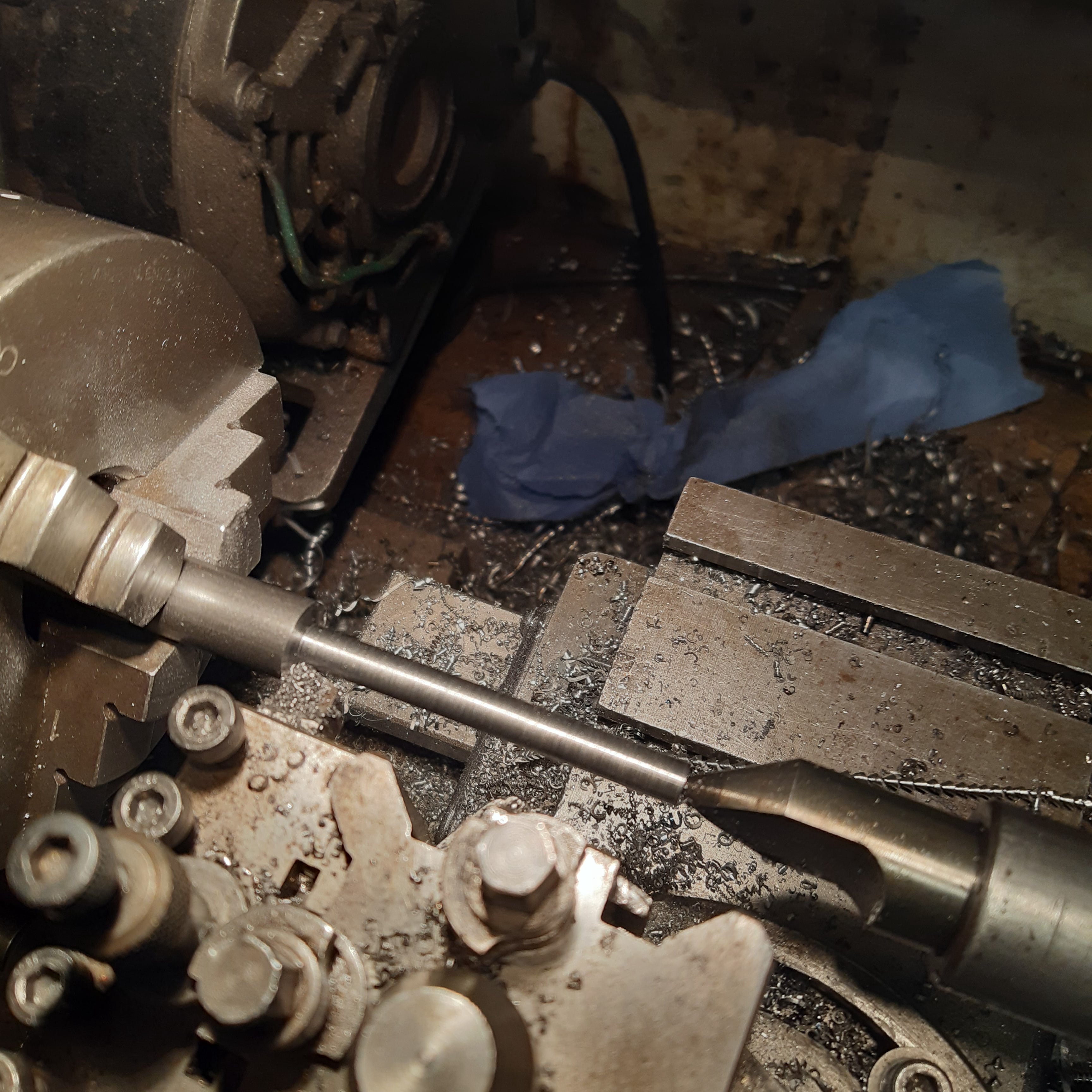

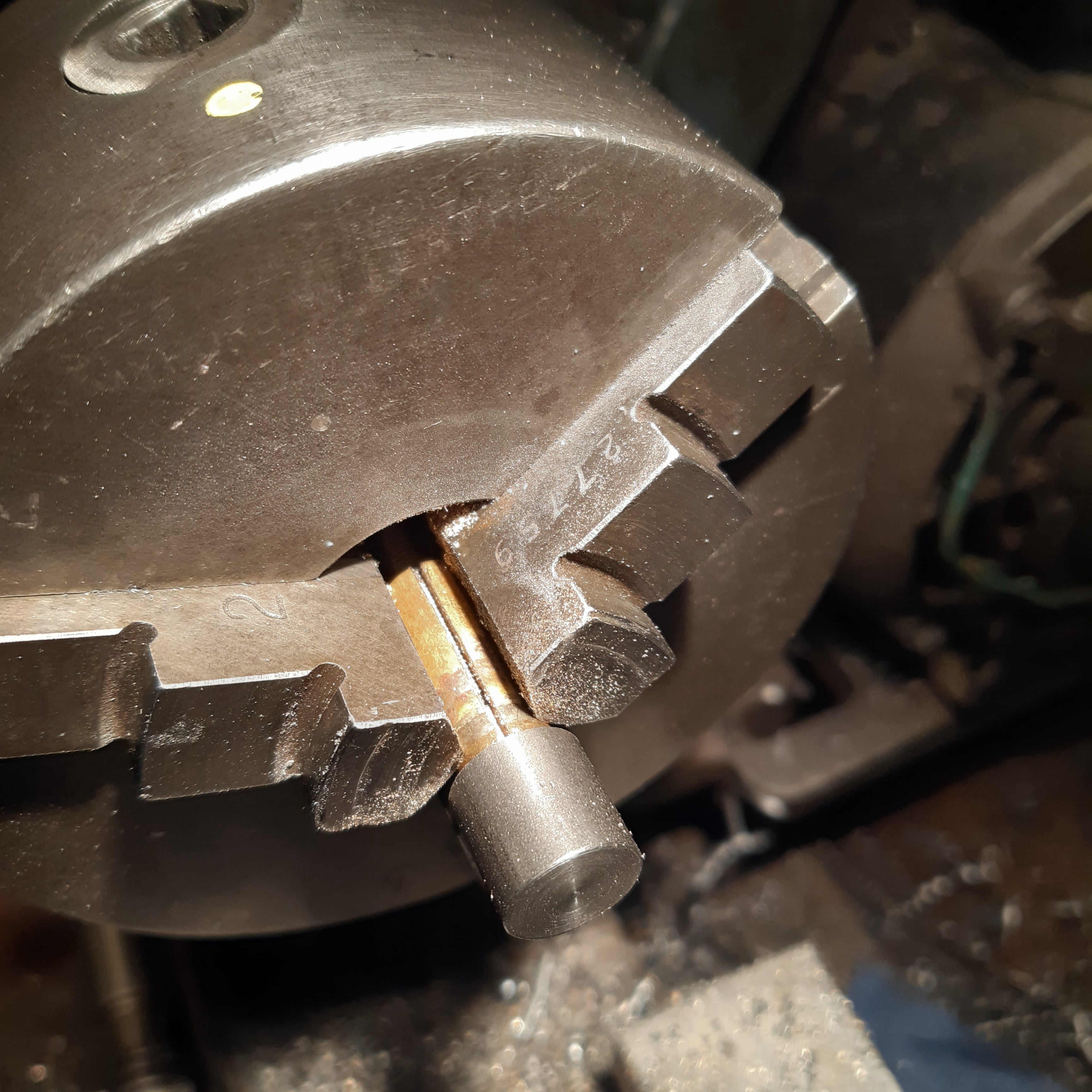

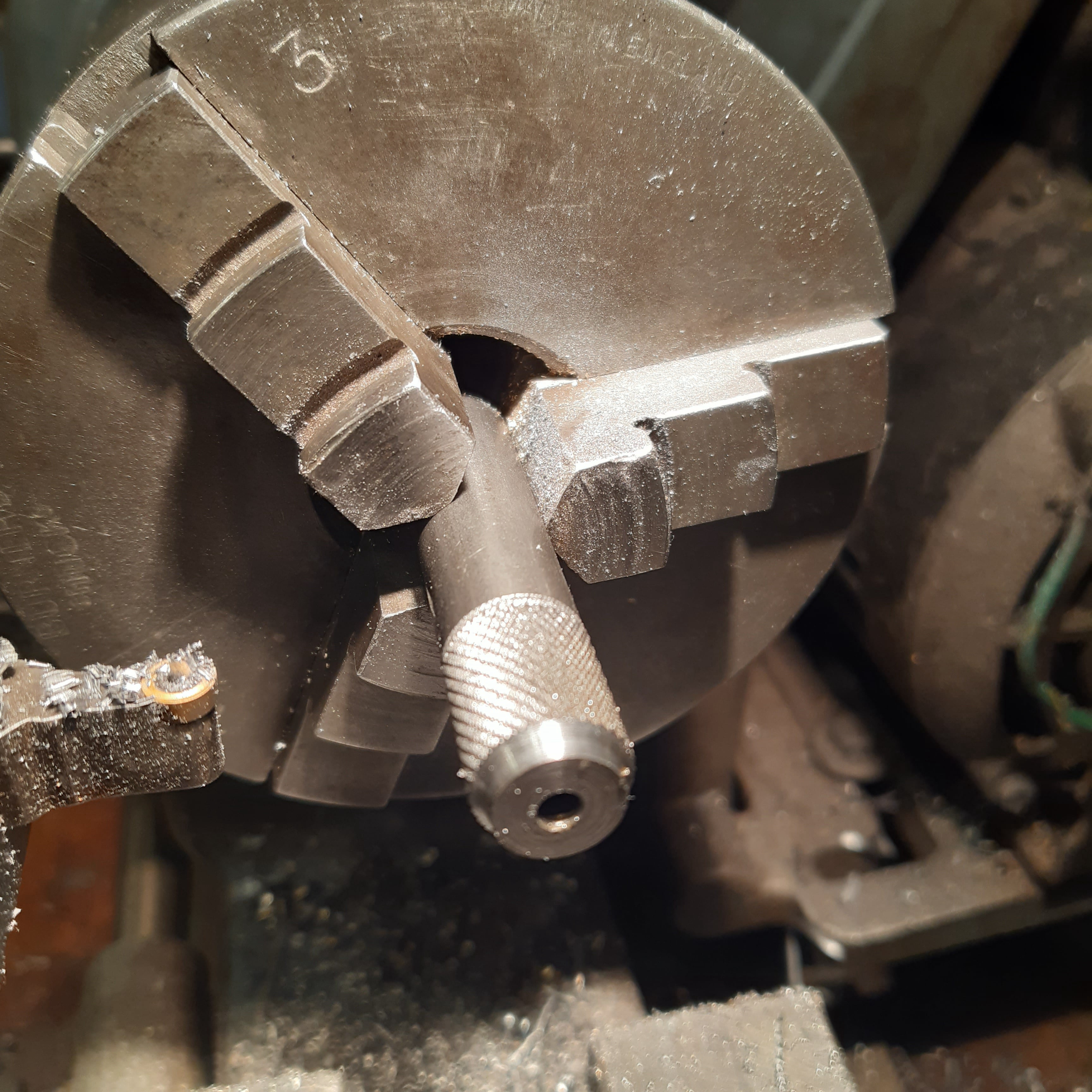

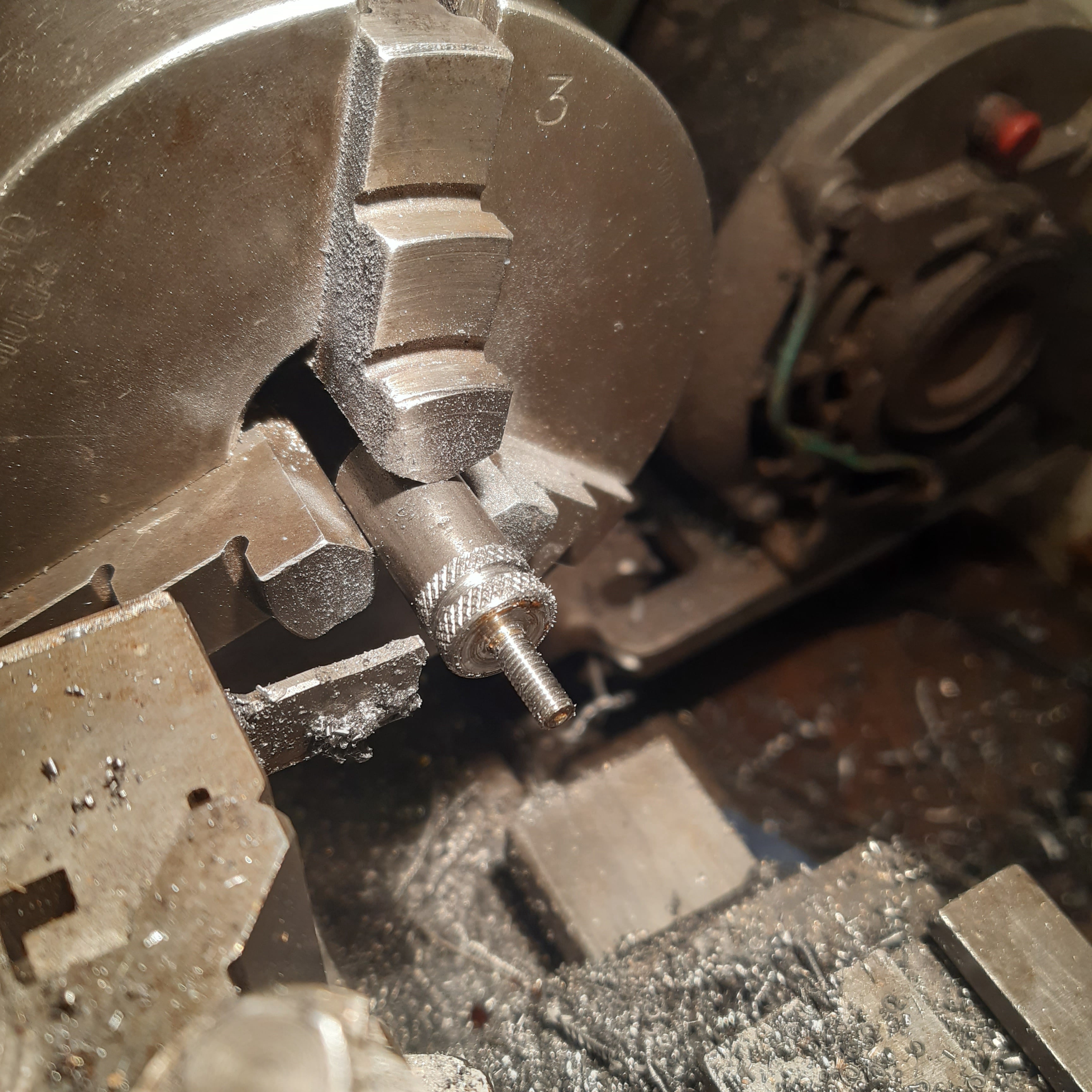

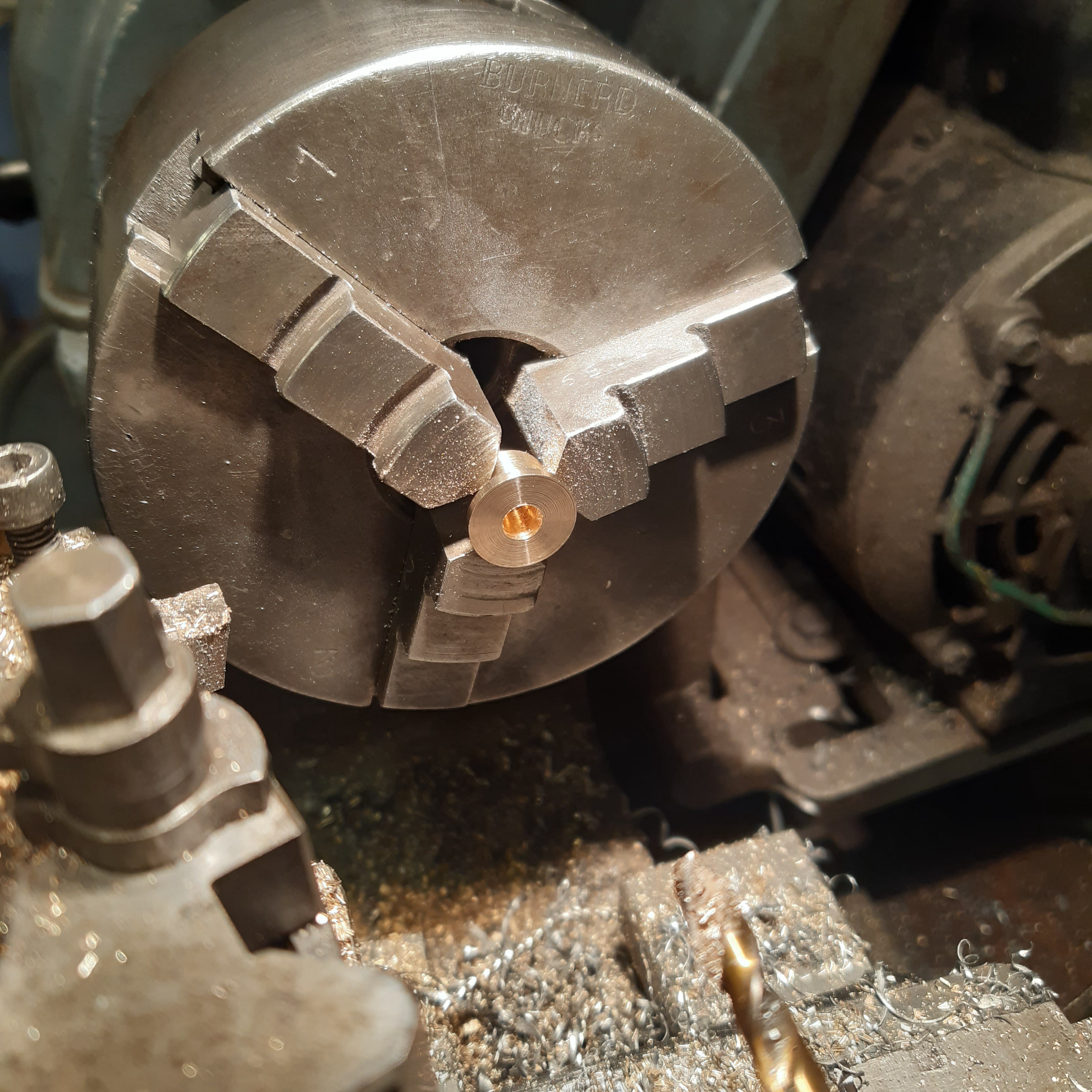

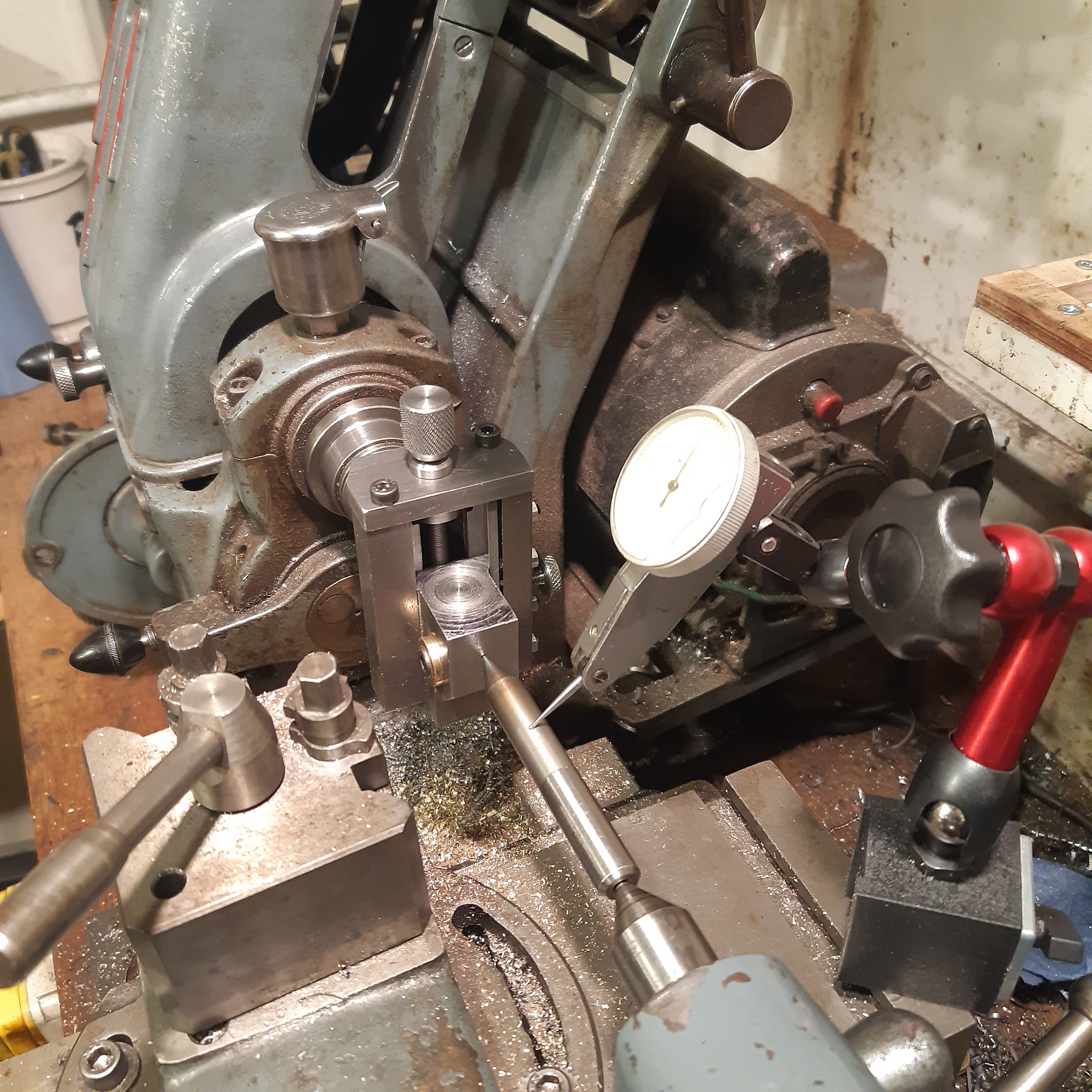

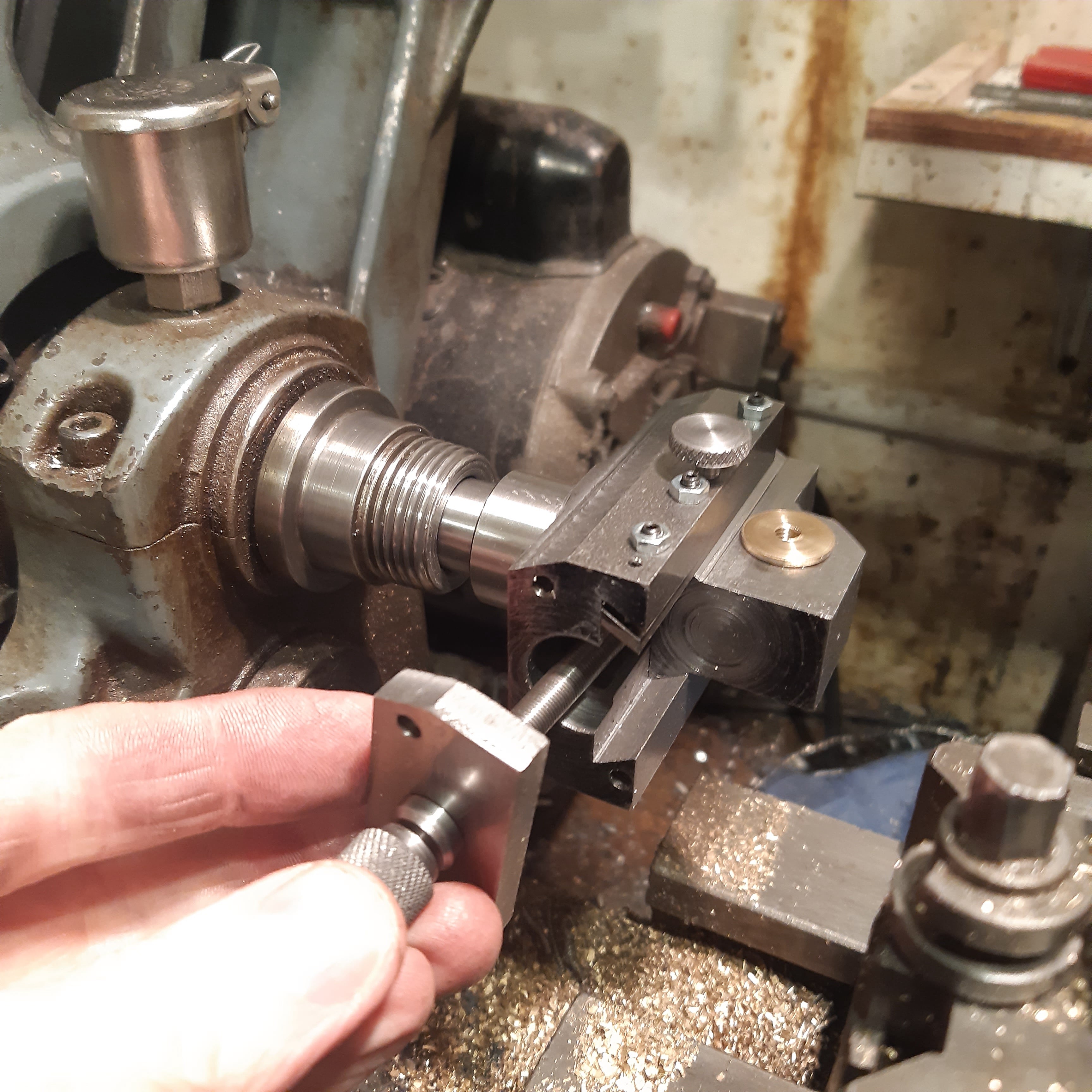

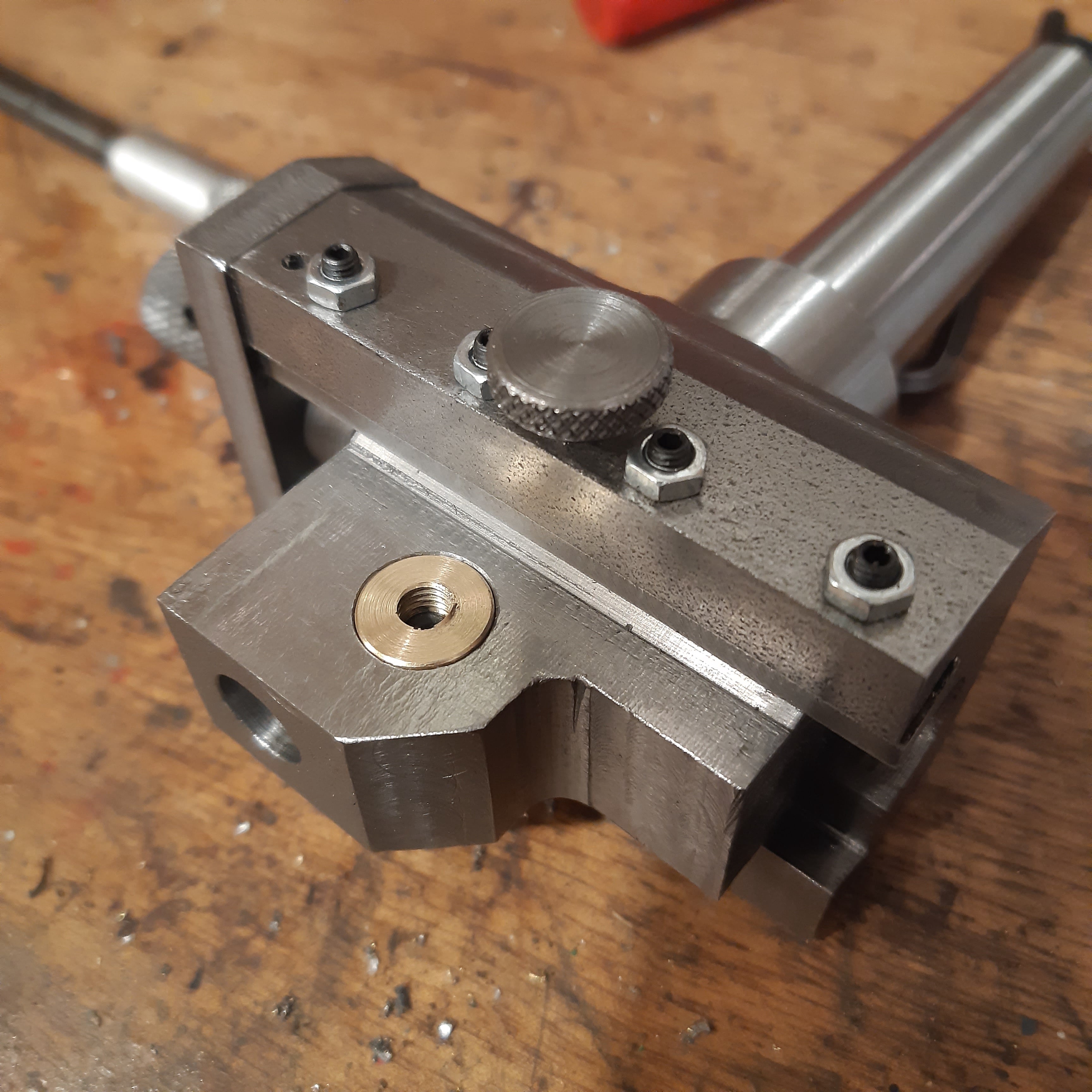

Another kit from Hemmingway Kits. This one was to make a boring head for the milling machine. A kit was purchased with an MT2 arbor.

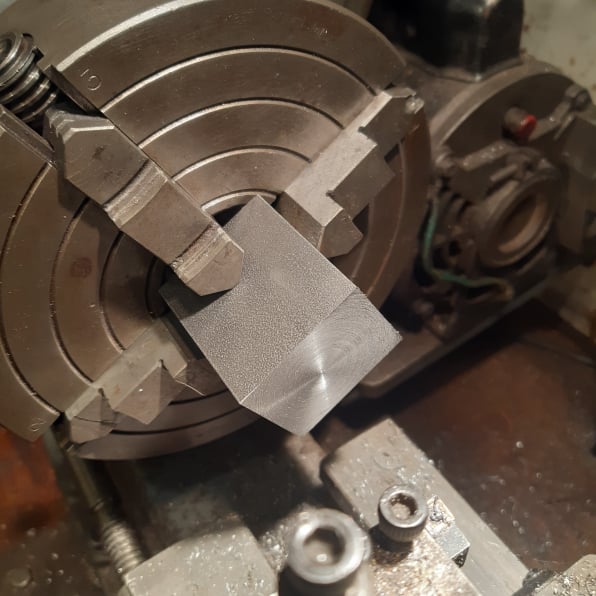

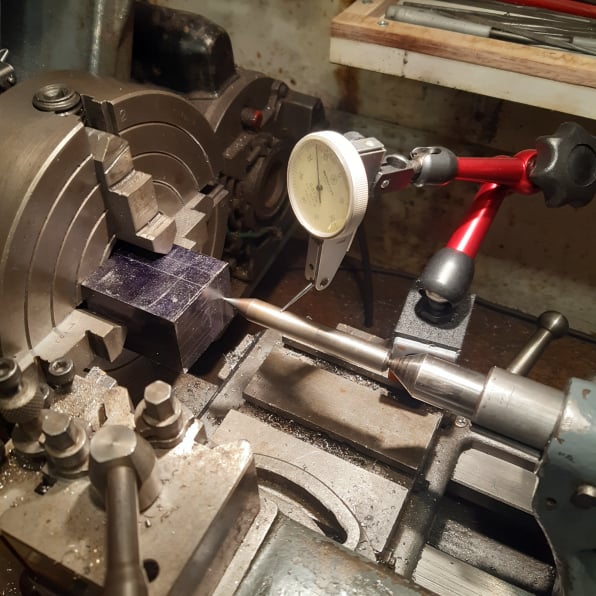

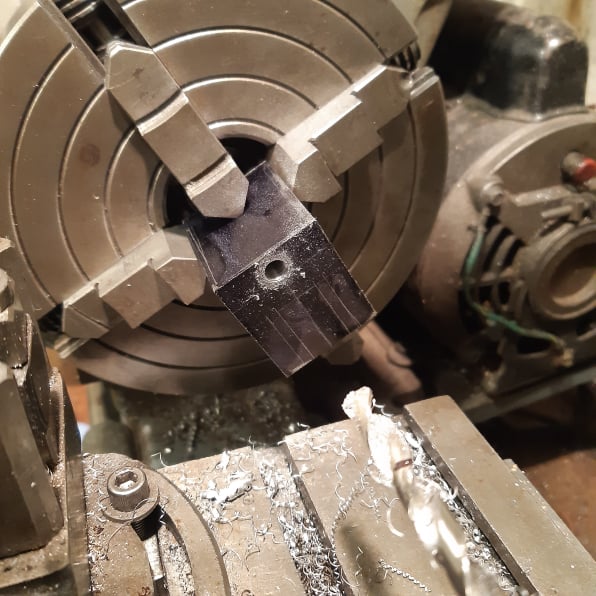

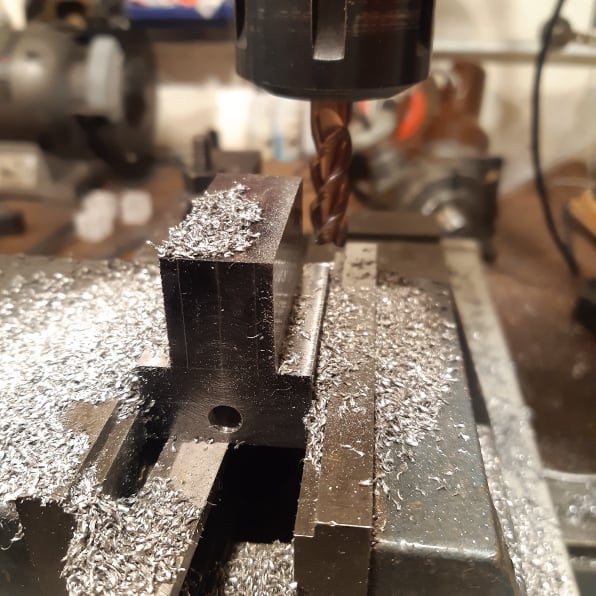

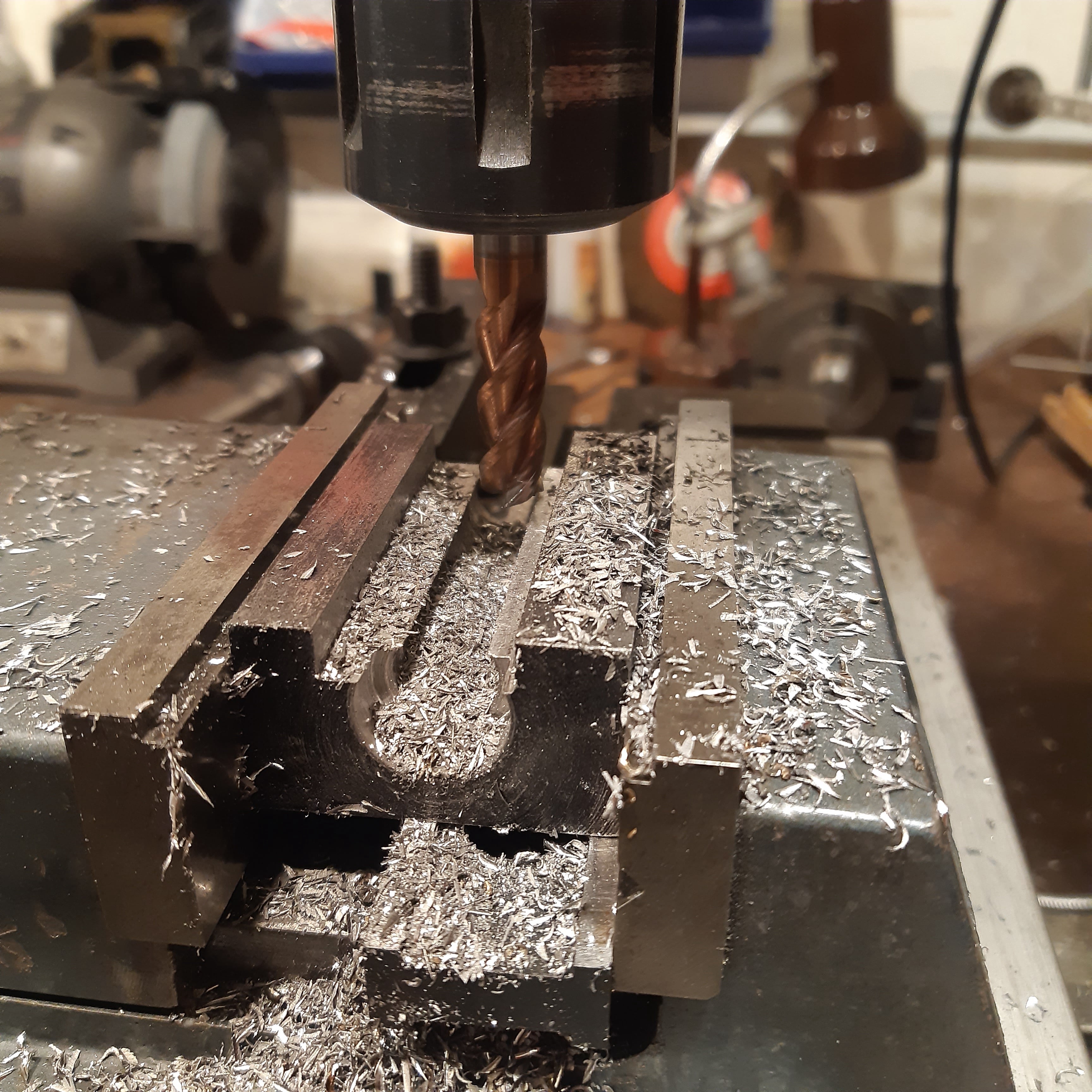

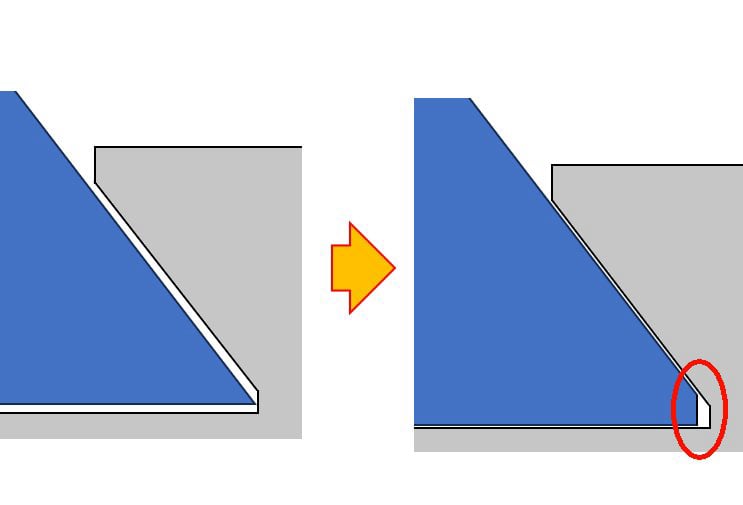

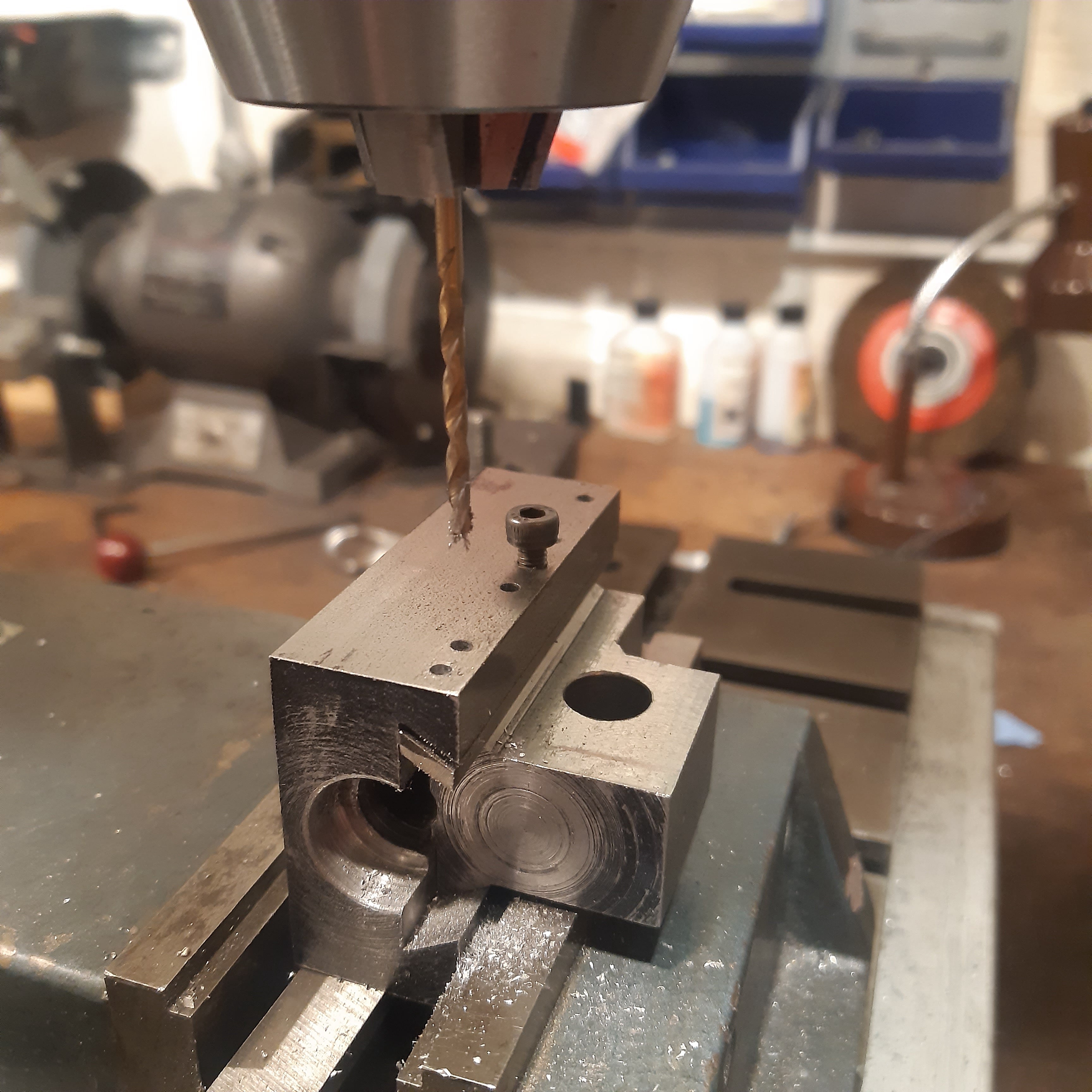

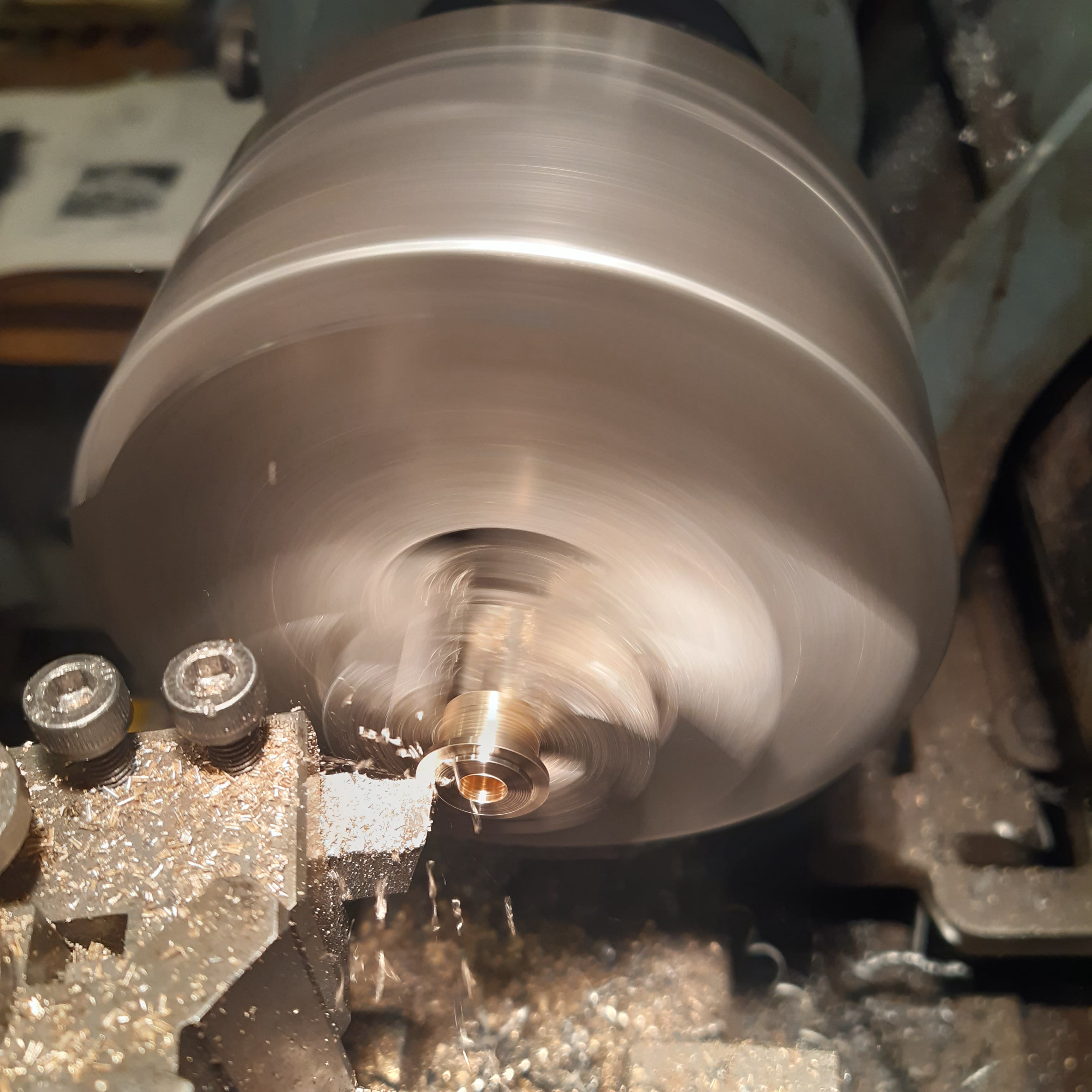

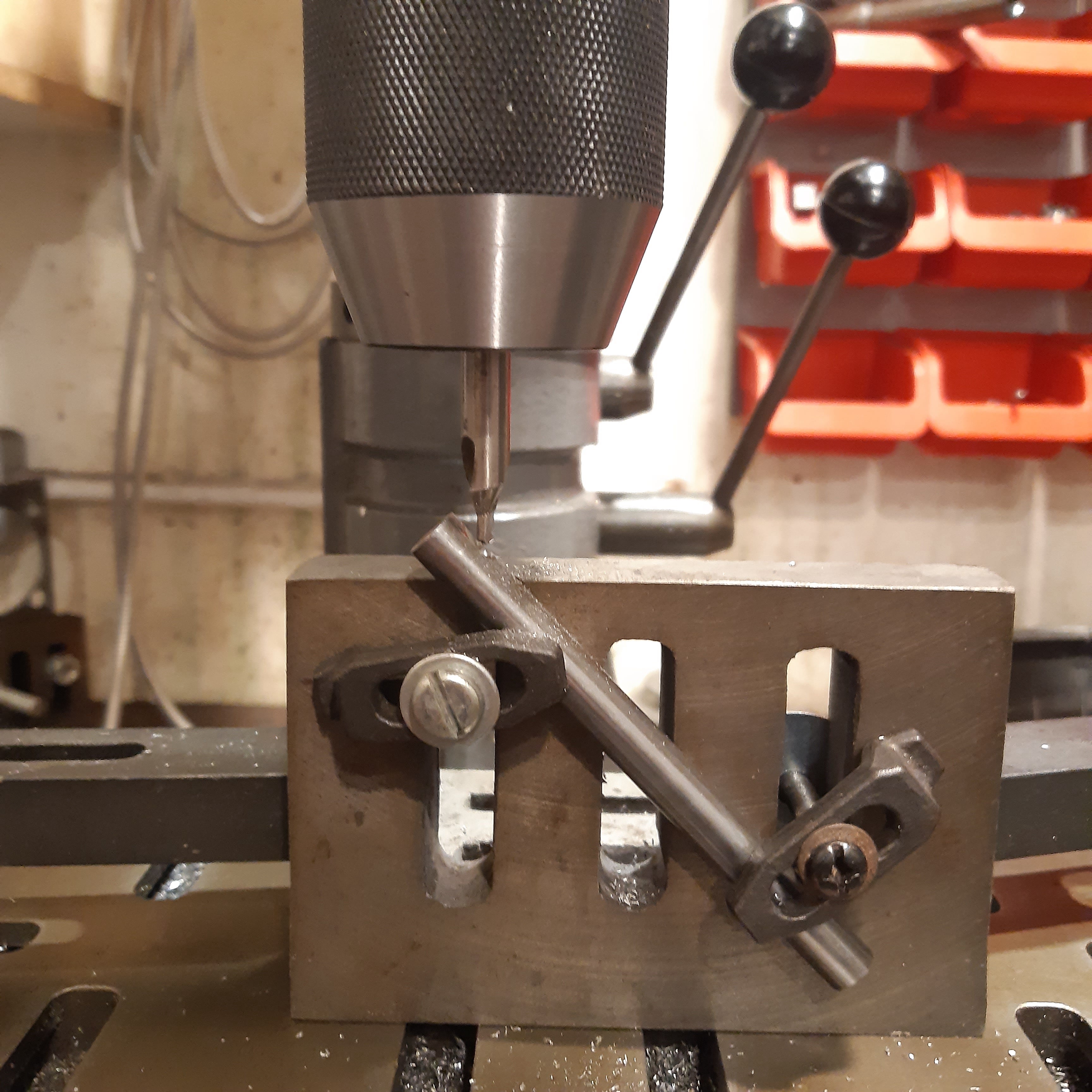

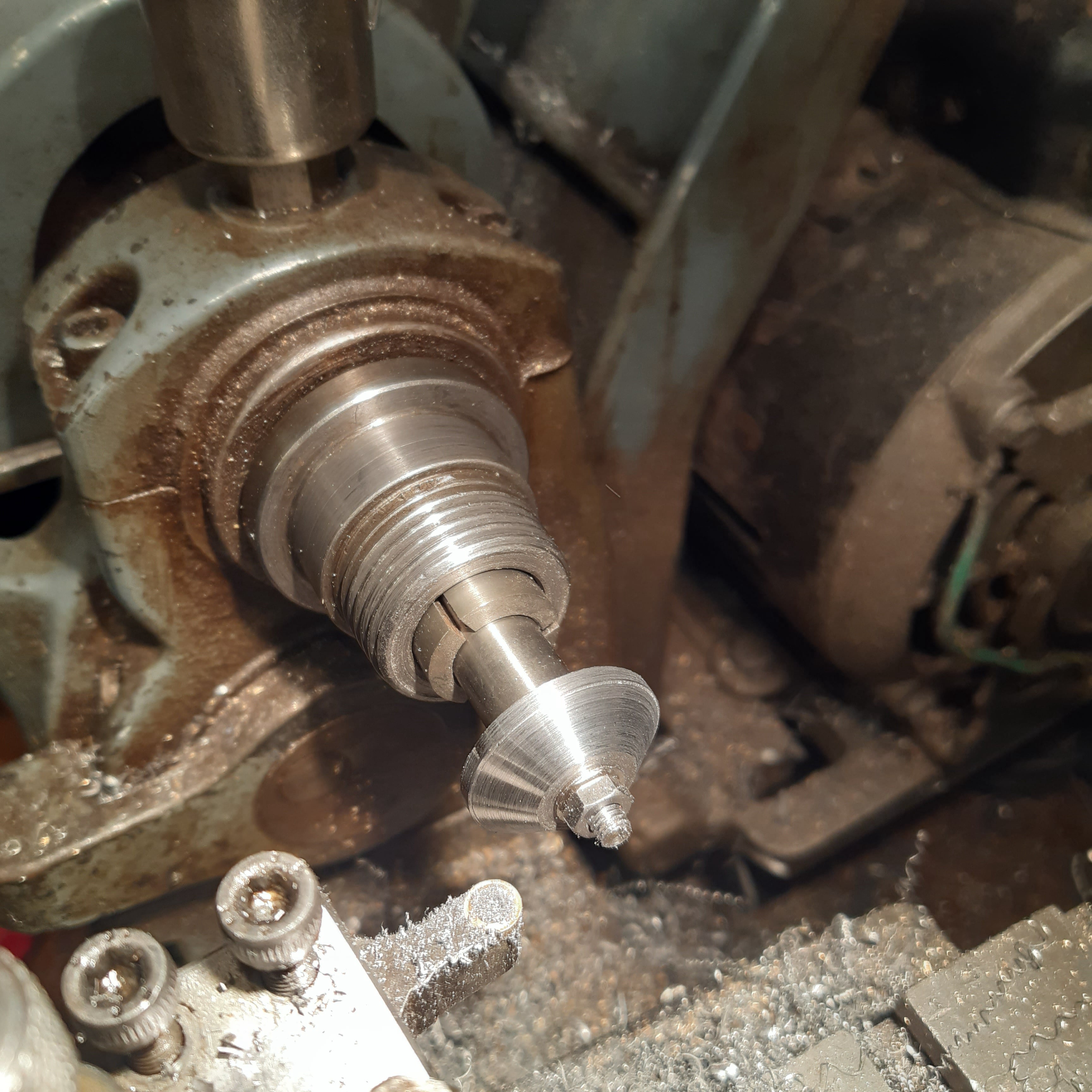

The design required the machining of a dovetail slideway, so a 60 degree milling cutter was also ordered.