Which 3D Printer?

There are many internet resources for 3D printing which give much more in depth information about 3D printing, but this document attempts to simplify the process of choosing a suitable machine.

This page only talks about FDM (fused deposition modeling) printers, as these are by far the most user friendly, cleanest and the cheapest way to get into 3D printing.

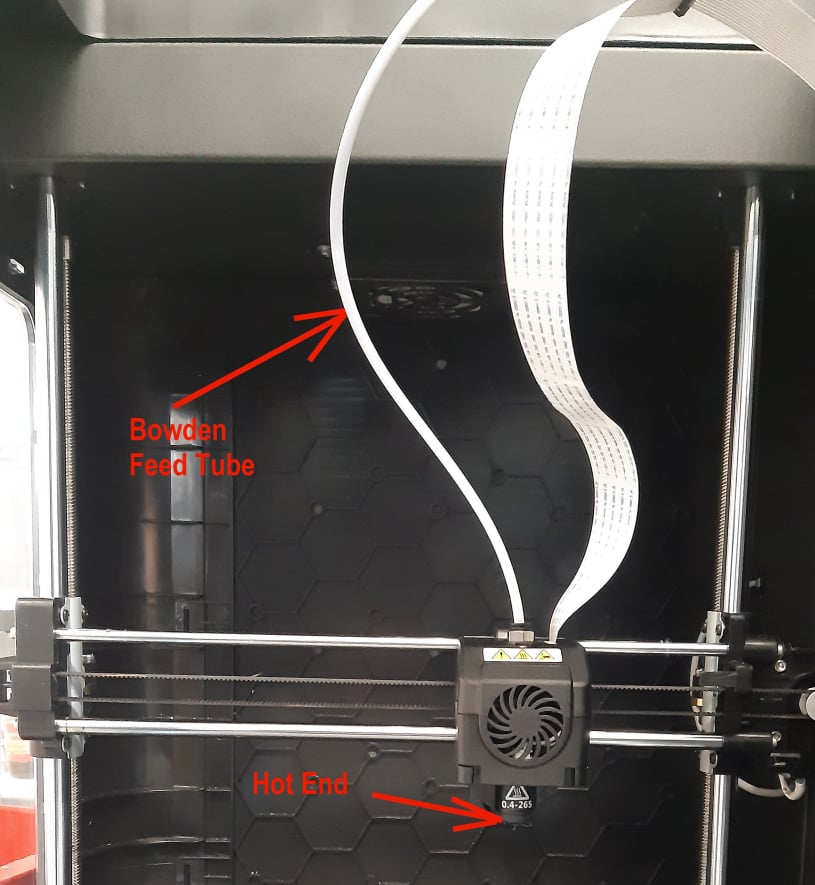

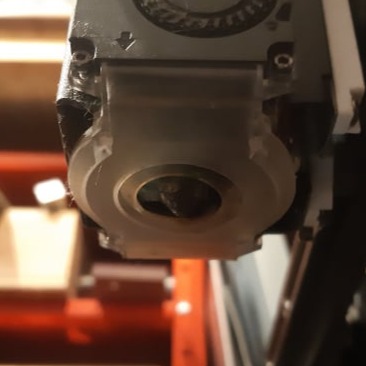

FDM printers work by feeding a plastic filament into a heated nozzle to deposit a thin bead on plastic on to the part. The nozzle is then moved in the X and Y axis to build up a layer of the part and then the Z axis can be incremented and the next layer produced. Most small printers have toothed belts to drive the X and Y axis where rapid motion is required, and then a screw feed for the Z axis.

As a simple approach to selecting an FDM printer, the decision can be based on 3 points.

- Print volume

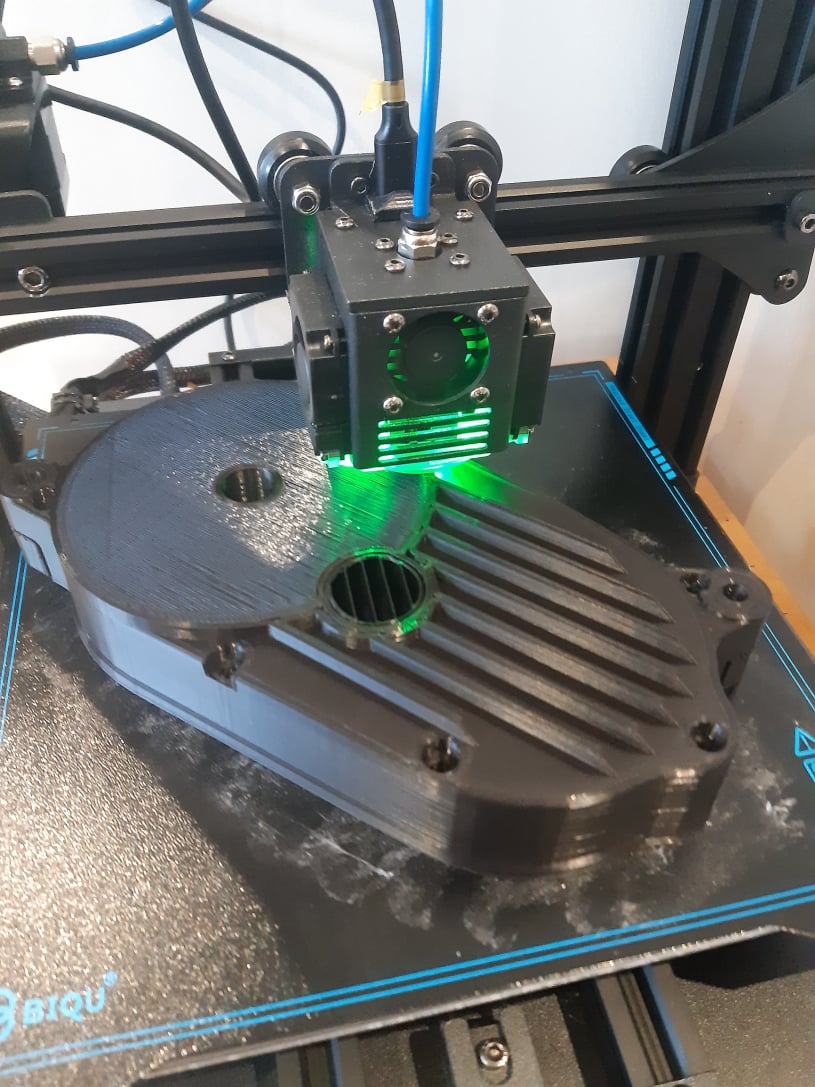

- Feed system

- Nozzle temperature

In all three cases, the answer to these criteria very much depends on what projects are anticipated.