The MK1 Steam Engine

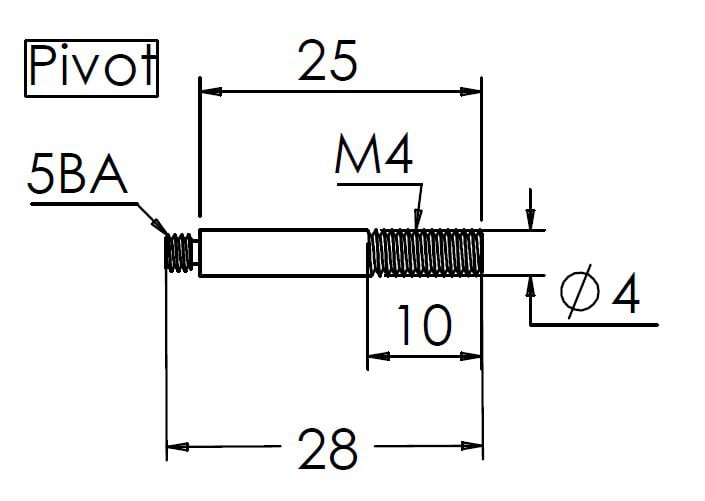

Pivot

The cylinder pivot is made from a silver steel rod of 4mm diameter.

It should be machined to ensure that there is a square shoulder at the root of the 5BA thread. This helps the pin to pull square to the cylinder port face when tightened.