The MK1 Steam Engine

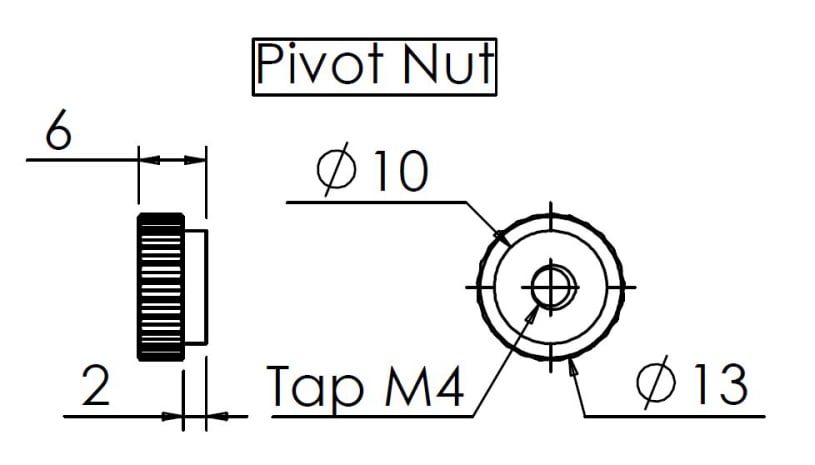

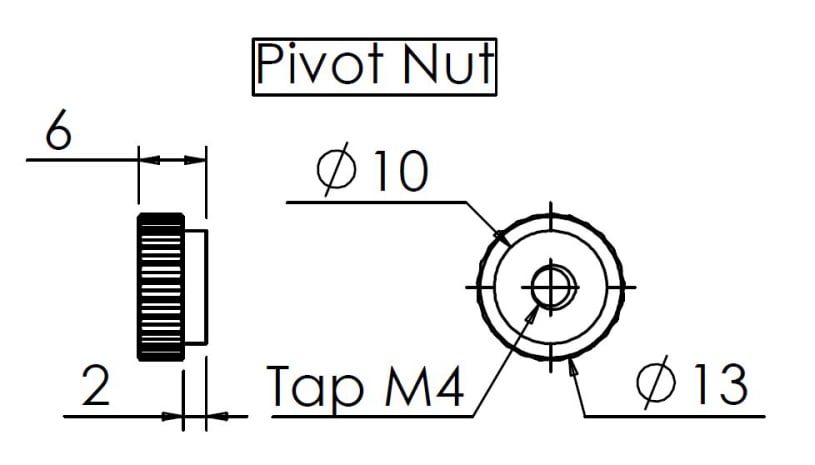

Pivot Nut

The pivot nut can be replaced with a standard M4 nut with washer, but this part gives the chance to try some knurling.

If a knurler is not available then a piece of hex bar would be a good substitute.

The pivot nut can be replaced with a standard M4 nut with washer, but this part gives the chance to try some knurling.

If a knurler is not available then a piece of hex bar would be a good substitute.

A blank for the nut can be turned from any piece of bar. None of the dimensions are critical on this part, aside from the thread which must match the pivot.

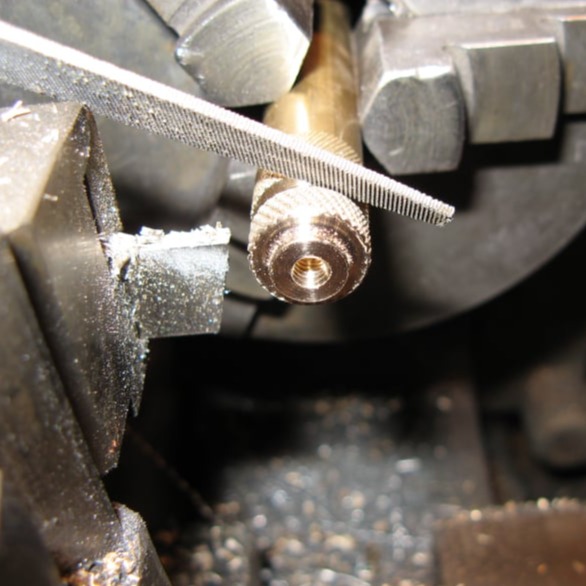

A clamp style knurler is the best to use if you have one. These have the advantage of applying a high knuling force without producing a high load on the lathe bearings. This is because the knurling force is maintained between the rollers.

To achieve maximum benefit the knurler should be opened just slightly smaller than the diameter of the bar.

The lathe needs a slow spindle speed and the knurler is wound in to start the knurl, then moved along the work piece to even out the knurling.

Before parting off the nut, the part can be centre-drilled, drilled and tapped with a thread to match the pivot.

For tapping - the tap can be held in the tail stock chuck, but the tailstock should not be locked to the lathe bed. Instead, hand pressure can be used to push the tailstock towards the work while the chuck is turned by hand.

Finally the nut is parted from the bar stock.

As with all parting the tool should be kept as short as possible to minimise vibrations, and the lathe used on its slowest spindle speed.

Part way through, if the tool is retracted, it is possible to use a file on the cut edge to deburr it, before the nut is parted off completely.

AI Website Maker