The MK1 Steam Engine

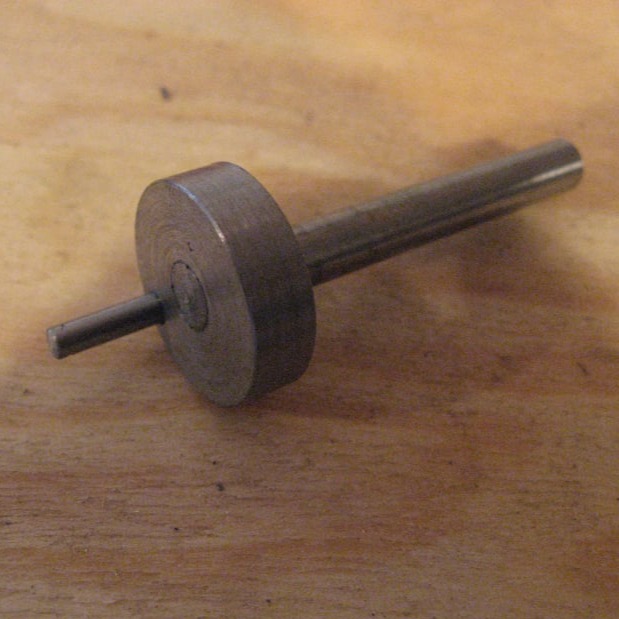

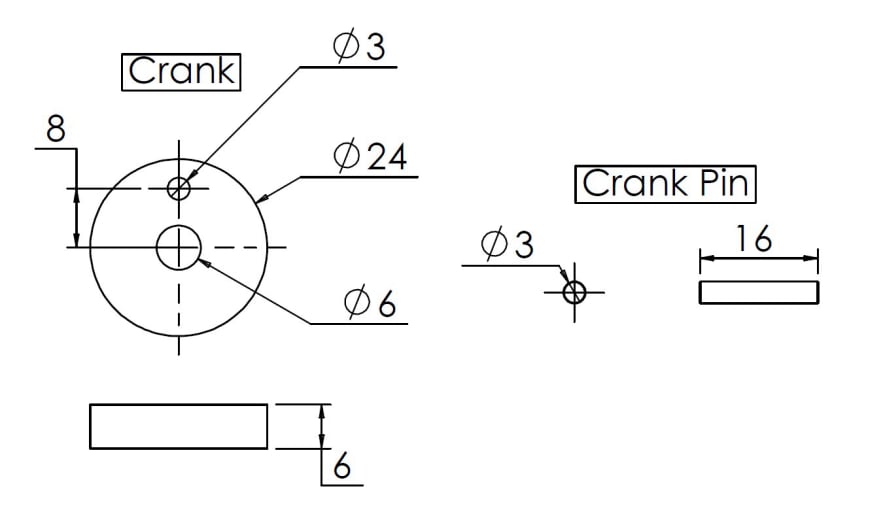

Crank and Crank Pin

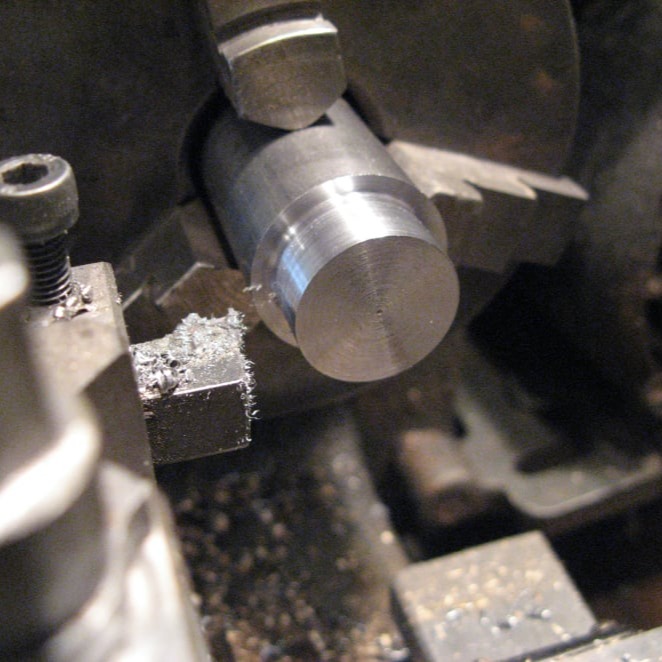

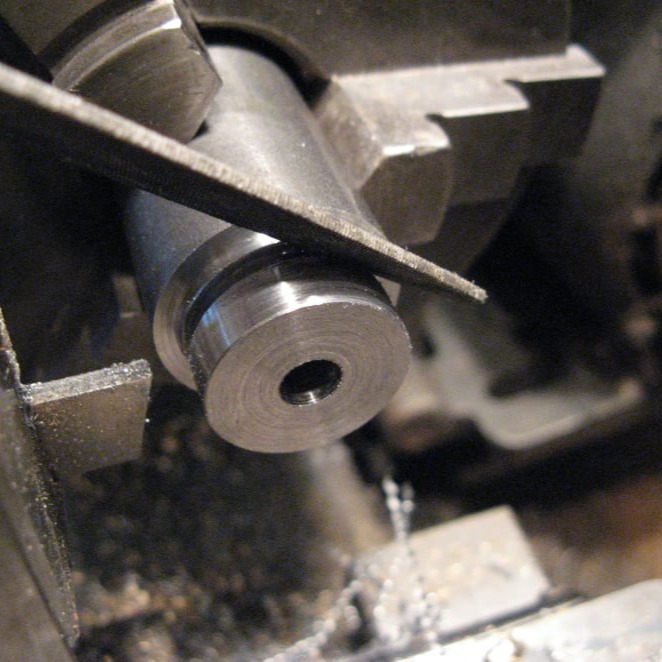

The crank is made from a piece of bright mild steel bar. For simplicity, a process to machine the off-set for the crank pin is described using some packing in the 3 jaw chuck of the lathe.

The crank pin is just a short length of silver steel rod.