The MK1 Steam Engine

Assembly and Testing

This page details some checks and tweaks you may need to get your engine running satisfactorily.

This page details some checks and tweaks you may need to get your engine running satisfactorily.

The engine should be assembled with some light oil on the running surfaces.

The first check is to turn the engine by hand to check for tight spots.

If there are problems, try just the axle in the bearing, just the piston in the bore and just the cylinder in the pivot.

If all is well with these checks then there is an assembly tolerance, most likely cause by the crank pin twisting in the big end bearing. To correct this, open out the big end hole to the next size up.

Next the engine can be tested on compressed air.

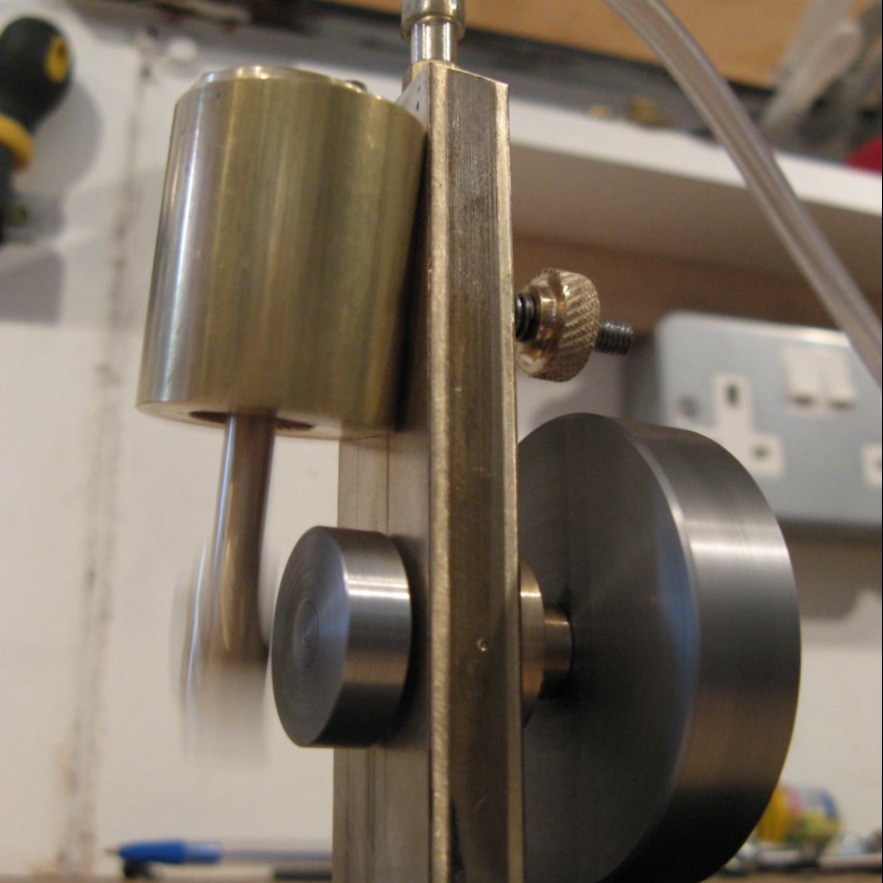

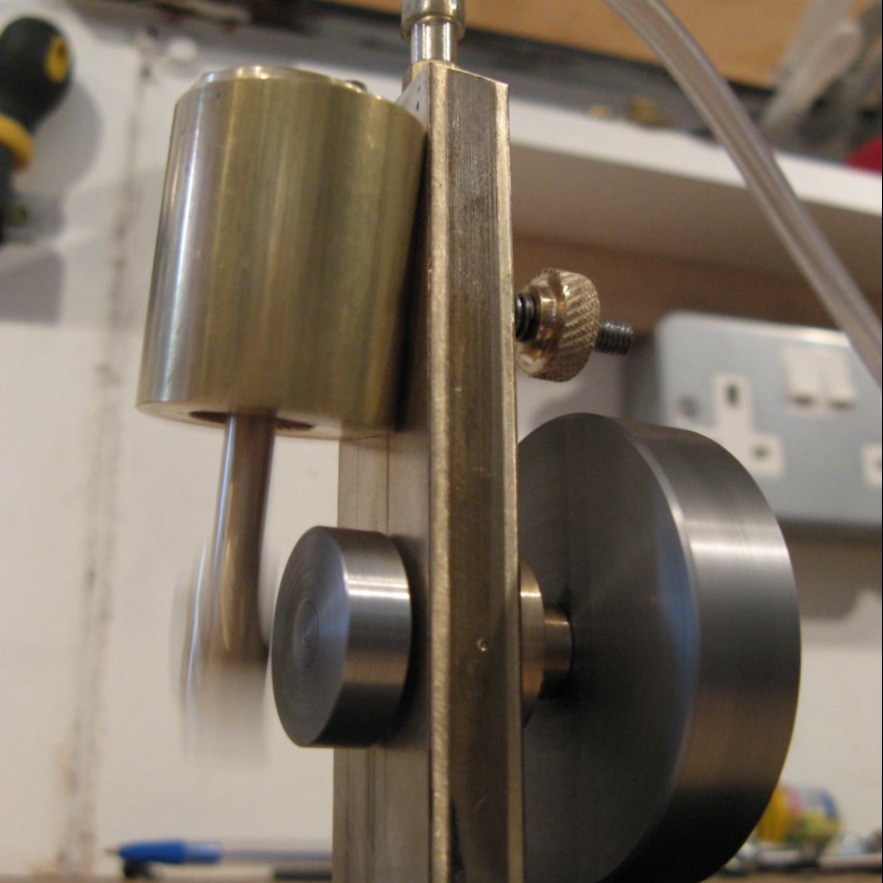

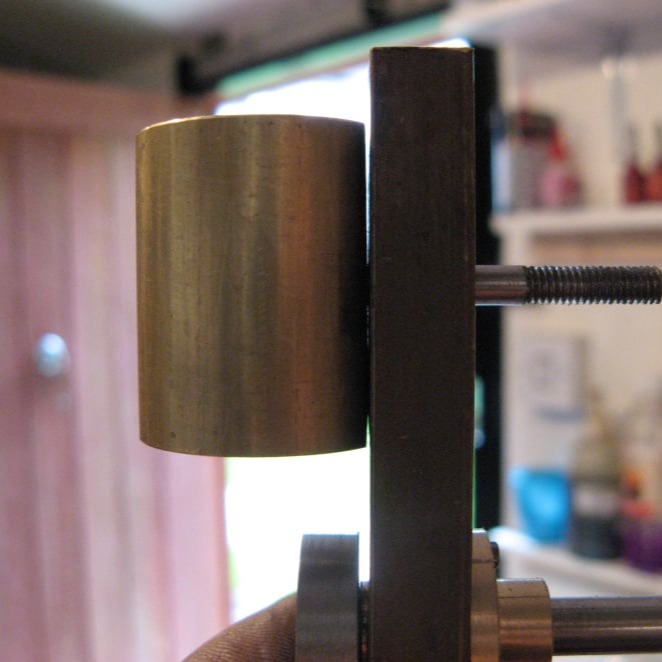

If there is air leaking at the port face, then check how close the cylinder sits to the frame (see above). Any gap here will let air/steam escape. By turning the cylinder over you should be able to work out if the pivot pin is not square in the cylinder or if the pivot hole is not square in the frame. Either way, opening out the pivot hole to the next size up will allow the spring to pull the cylinder square to the face.

A short video of the engine running on compressed air.

A second video of the engine running on steam.

For boiler plans go here.

No Code Website Builder