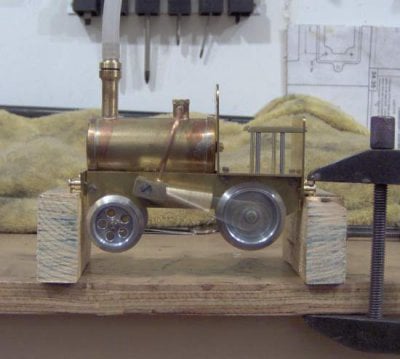

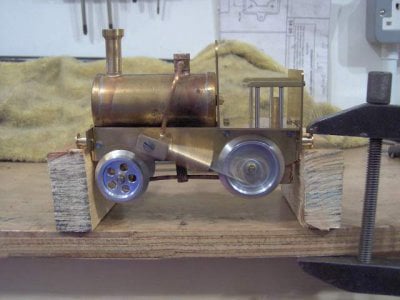

0 Gauge Locomotive - "Dickins"

This locomotive design was by a model engineer called Dr. James R. Senft and the construction was detailed in 'Live Steam Magazine' in 1976.

The best description of the design, is given by the article itself :

"Dickins was inspired by a photograph of a British toy locomotive dating back to 1890. Although differing in mechanical detail, Dickins shares the general appearance of its larger antique toy prototype and consequently shares its quaint charm.................Dickins was designed to run on standard O-gauge toy track - the kind supplied with clockwork train sets - or on Lionel 027 track. The locomotive has ample power and speed for its class. It carries enough fuel and water for a 20 minute run pulling 2 tinplate cars around a 2ft-diameter circle of track, at a rate in excess of 2.5 feet per second."